Explore GEP ECOTECH for the Latest Updates on Our Developments

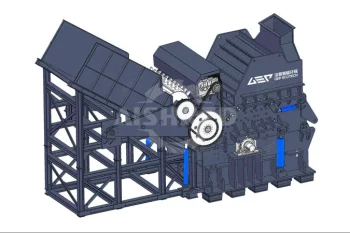

GEP ECOTECH proudly announces the launch of its next-generation waste wood shredder, an advanced machine engineered to meet the…

May 19, 2025

The traditional RDF (Refuse-Derived Fuel) production process mainly relies on heavy-duty single shaft shredders for shredding…

Mar 24, 2025

Scrap Aluminum Shredder is a kind of shredding equipment used to process scrap aluminum, which is mainly used for the shredding…

Nov 29, 2024

Many people are looking for hazardous waste disposal companies or hazardous waste disposal sites near them. GEP ECOTECH has…

Nov 19, 20245-gallon paint buckets are a common sight in home renovations and industrial projects. While these buckets are sturdy and…

Sep 13, 2024

When it comes to shredding tires, there are various equipment options available, such as single-shaft or dual-shaft shredders.…

Sep 10, 2024

In the process of waste tire recycling, the complete separation of rubber and steel wire directly impacts the purity of the output and the efficiency of downstream processing. As a leading solid waste treatment technology company, GEP ECOTECH has developed a high-performance tire steel wire separator to provide…

Building a WEEE recycling and treatment center requires strategic planning, advanced technology, and compliance with international environmental standards. This guide outlines a comprehensive framework for entrepreneurs, investors, and organizations seeking to enter the global e-waste management market. It emphasizes…

In the face of rising plastic waste, especially lightweight and flexible materials like PET bottles, PE films, and PP woven bags, the need for reliable, small-scale shredding equipment is growing rapidly. GEP ECOTECH's small shredder machine for plastic is engineered to provide a compact, cost-effective, and efficient…

GEP ECOTECH proudly announces the launch of its next-generation waste wood shredder, an advanced machine engineered to meet the growing demand for high-performance wood waste processing. Tailored for handling diverse types of waste wood—such as wood pallets, logs, trimmings, boards, and construction offcuts—the new…

Lithium-ion battery cathodes are vital to the performance of modern energy storage systems. They are typically composed of high-value materials such as lithium cobalt oxide (LiCoO₂), nickel-cobalt-manganese (NCM), or lithium iron phosphate (LiFePO₄), coated onto aluminum foil current collectors using polyvinylidene…

In the field of solid waste resource utilization, air separators play a crucial role as key equipment. GEP ECOTECH, a pioneer in solid waste treatment, offers a series of high-performance air separators with advanced technology and extensive industry experience. These separators provide efficient and precise sorting…

Tire debeaders, also known as tire bead wire removers, play a crucial role in the waste tire recycling process. These machines are specifically designed to extract the thick steel wires embedded in the bead of large tires, such as those used on trucks, buses, and off-the-road (OTR) vehicles. This machine can be…

Paper converting and printing facilities generate significant volumes of pre-consumer waste during cutting, trimming, binding, and packaging processes. This waste includes edge trim, roll ends, misprints, matrix waste, and other offcuts—materials that are typically clean but bulky, and difficult to handle efficiently…

As urban waste volumes grow, the demand for efficient, space-saving, and cost-effective waste management becomes more urgent. GEP ECOTECH's horizontal hydraulic baler stands out as a smart solution that complements solid waste treatment lines, particularly in municipal solid waste (MSW), packaging recycling, and bulky…

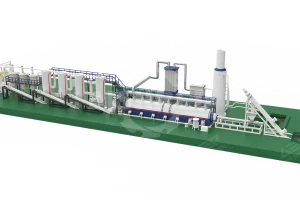

GEP ECOTECH offers a state-of-the-art continuous waste tire pyrolysis system designed to convert scrap tires into valuable products such as pyrolysis oil, carbon black, steel wire, and syngas, with near-zero emissions and continuous, automated operation. This technology is ideal for investors seeking sustainable and…

With growing environmental awareness and the global shift toward sustainable energy, RDF (Refuse Derived Fuel) is gaining traction across industries. TDF (Tire Derived Fuel), a significant branch of RDF, is increasingly valued for its ability to transform waste tires into valuable fuel. By shredding scrap tires into…

With the rising number of end-of-life vehicles (ELVs) worldwide, the recycling of automotive shells has become a strategic necessity in the resource recovery and green manufacturing sectors. Automotive body shells are typically composed of high-strength steel, aluminum, copper, plastic composites, insulation materials…

As nations accelerate their transition to carbon neutrality, power plants are increasingly adopting biomass co-firing in Circulating Fluidized Bed (CFB) boilers to reduce coal dependency and decarbonize energy production. This shift not only aligns with global climate goals but also unlocks the potential of…

Ghost nets—abandoned fishing nets, are a major threat to the environment, marine life, and human activity. These nets don't degrade easily and continue to trap and kill fish, turtles, and seabirds, damaging the marine ecosystem. Made from plastics like nylon and PE, they can break down into microplastics that enter…

Wood shredder is an efficient and reliable solid waste treatment equipment widely used in fields such as wood recycling, biomass energy preparation, and garden green waste treatment. According to the different types, volumes, and final application requirements of the processed materials, they can be subdivided into…

In today’s fast-growing plastic recycling industry, the performance of shredding equipment directly impacts both the quality and cost-efficiency of resource recovery. Facing a wide range of plastic waste—from soft packaging films to hard and thick materials—many traditional shredders fall short due to limited…

In the solid waste treatment and recycling industry, many operators face a common challenge — their existing shredders underperform due to worn-out or poorly matched cutter boxes, blades, or shafts. Instead of replacing the entire machine, upgrading key components can significantly improve performance, efficiency, and…

For many plastic manufacturers, plastic lumps and purging waste are a real headache. These solid, irregular, and oversized chunks—generated during injection molding, extrusion purging, or machine clean-outs—are hard to manage and even harder to recycle without the right equipment.Traditional granulators can’t handle…

As the global photovoltaic (PV) industry matures, a new wave of challenges is emerging: the large-scale retirement of aging solar panels. With a typical lifespan of 25–30 years, the first generation of solar modules is reaching its end-of-life, leading to a surge in decommissioned PV components.To address this growing…

When using pyrolysis to process plastic waste, the purity of the plastic and the presence of contaminants such as paper, metals, glass, dirt, or non-plastic materials can interfere with the pyrolysis process and reduce the quality of the output. Generally speaking, the plastics entering the pyrolysis reactor should…

The maximum water content in the material entering a pyrolysis reactor is a critical factor for ensuring efficient and effective operation. Excess moisture can negatively impact the pyrolysis process, leading to higher energy consumption, reduced output quality, and potential operational issues. Here's a detailed…

In today's rapidly developing solid waste treatment industry, efficient and precise metal processing technology has become the core competitiveness for improving resource regeneration efficiency. Faced with the processing pain points of high hardness, complex shapes, and sensitive properties of waste metal materials,…

Carbon black is one of the important products of tire pyrolysis, accounting for 30%-35% of tire pyrolysis products, second only to pyrolysis oil. The calorific value can reach 7000 kcal, which is equivalent to coal. After being made into carbon black balls by a briquette machine, it can replace coal in industrial…

Waste tires contain bead wires, which, if not removed, may cause increased wear and even damage to equipment such as tire shredders. The use of tire debeader can effectively reduce equipment wear and maintenance costs. At the same time, it can greatly improve the efficiency of waste tire processing, reduce…