The recycling of waste tires has always been an important environmental issue. Tire grinding, as an important way to recycle waste tires, can convert waste tires into valuable rubber powder, which can then be used in multiple fields such as recycled rubber, waterproof materials, sports facilities, etc., to achieve the recycling of resources and reduce environmental pollution.

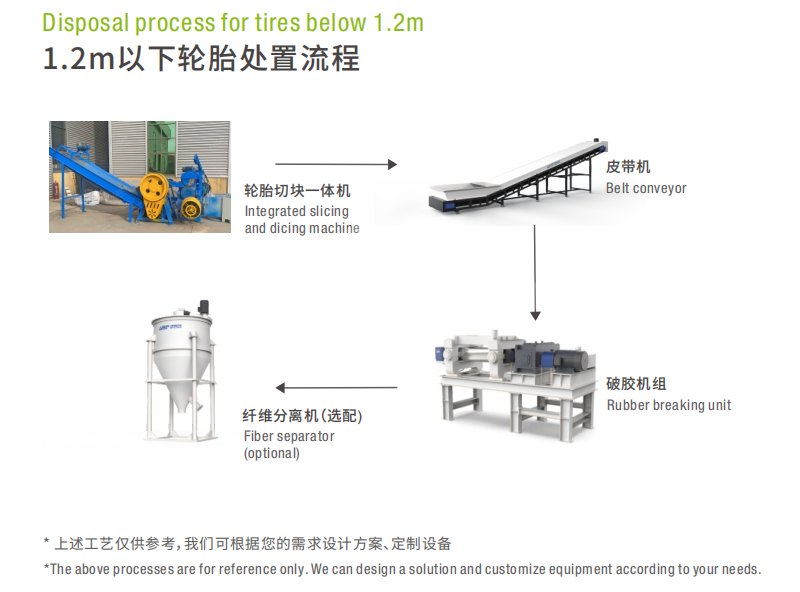

In the field of waste tire recycling, GEP ECOTECH has always been adhering to the spirit of exploration and innovation, and is committed to providing customers with efficient and environmentally friendly solutions. Recently, based on new market changes and demands, we have launched a cost-effective tire grinding and disposal production line, which can prepare tires with a diameter of less than 1.2m into rubber powder. The disposal process is as follows:

Features

Simplify the process flow

The integrated slicing and dicing machine integrates the dual functions of cutting and crushing, and can directly cut the entire tire into rubber blocks of about 50 mm, improving processing efficiency. In addition, it also replaces the two equipments of the tire bead machine and the tire shredder, reducing the floor space and energy consumption, making the production line more compact.

High cost performance

Compared with traditional shredders, the price of integrated slicing and dicing machine is only tens of thousands of dollars, which greatly reduces the investment threshold, allowing more small and medium-sized investors to afford this equipment and participate in the waste tire recycling industry.

Flexible Configuration

In order to meet the needs of different customers, we designed the fiber separator as an optional device. Customers can choose whether to configure this device according to the specific needs of the back-end application.

Customized service

The entire production line can also be customized according to the customer's production scale, site conditions and some other personalized requirements to ensure that customers can get the most suitable solution for themselves

If you are looking for efficient and environmentally friendly tire recycling solutions, please feel free to contact us. We will provide you with the most professional technical support and services, and work together to create a green future!