The biomass blending process is a technology that combusts biomass fuels in a mixture with traditional fossil fuels (e.g., coal, oil, etc.). This practice reduces dependence on fossil fuels and lowers greenhouse gas emissions, while also utilizing waste resources and contributing to environmental protection and sustainable development. gas emissions, while also utilizing waste resources, contributing to environmental protection and sustainable development.

Pretreatment of biomass prior to blending is a critical step to ensure that biomass materials can be efficiently and stably blended with fossil fuels for combustion. The pre-treatment process usually includes crushing, drying, sieving, mixing, etc., with the aim of adjusting the biomass feedstock to a condition suitable for blending.

The biomass blending pre-treatment system uses a variety of equipment to prepare the biomass fuel so that it is suitable for combustion with traditional fossil fuels (e.g., coal) or for individual high-efficiency energy conversion.

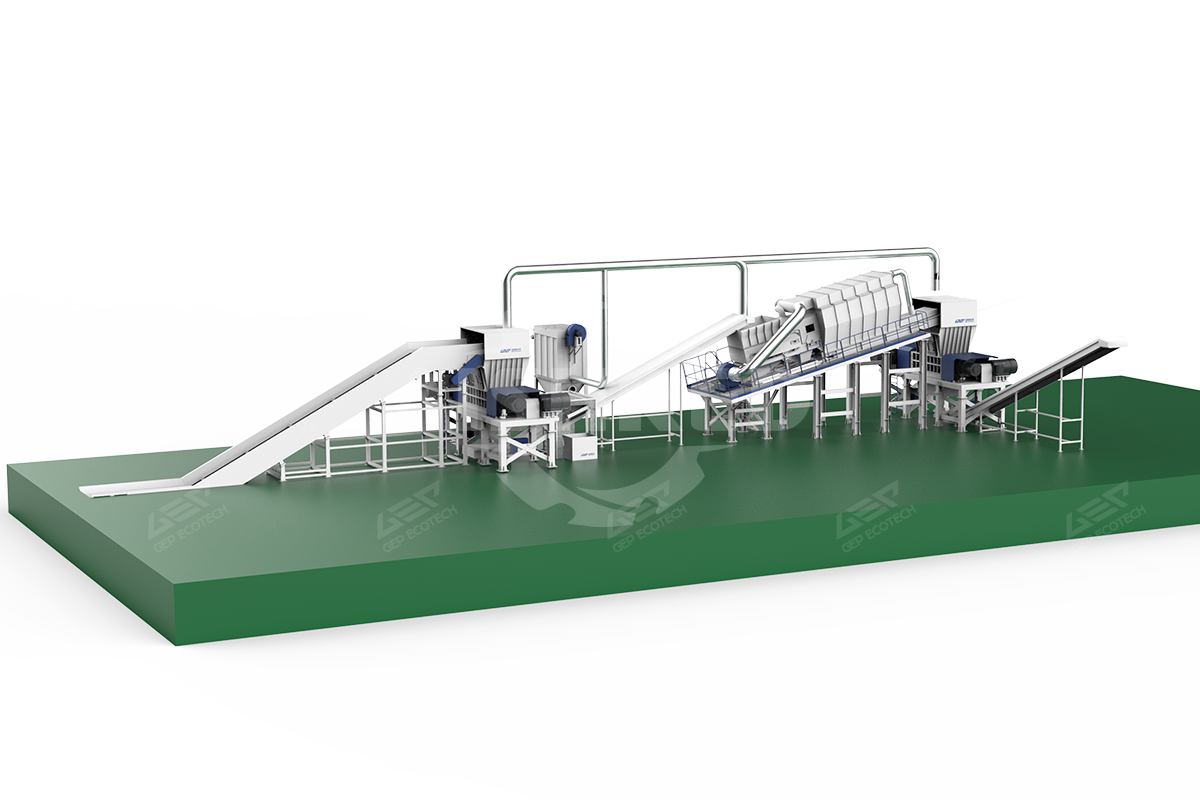

GEP ECOTECH's biomass pre-treatment system adopts the process of “feeder – pre-shredding - fine shredding - dust removal system - feeding system”. Drawing on European technology and through innovative product design, the overall system requires only 1-2 people to work, with a high degree of automation. For round bundles, square bundles, bulk material after two stages of shredding, they were fed into the combustion system. The whole process is environmental protection and high efficiency.

Biomass co-firing is a technical solution that is both beneficial to energy conservation and emission reduction and has economic benefits, but its specific application still needs to consider various factors according to the actual situation. With the advancement of relevant research and technology, it is expected that there will be more innovation and development in this field in the future.