Biomass coupling is an innovative energy utilization method that combines biomass energy with traditional fossil fuels to generate electricity, thereby enhancing energy efficiency. Its unique technological advantages and environmental benefits have become a significant driver for the sustainable development of the energy sector.

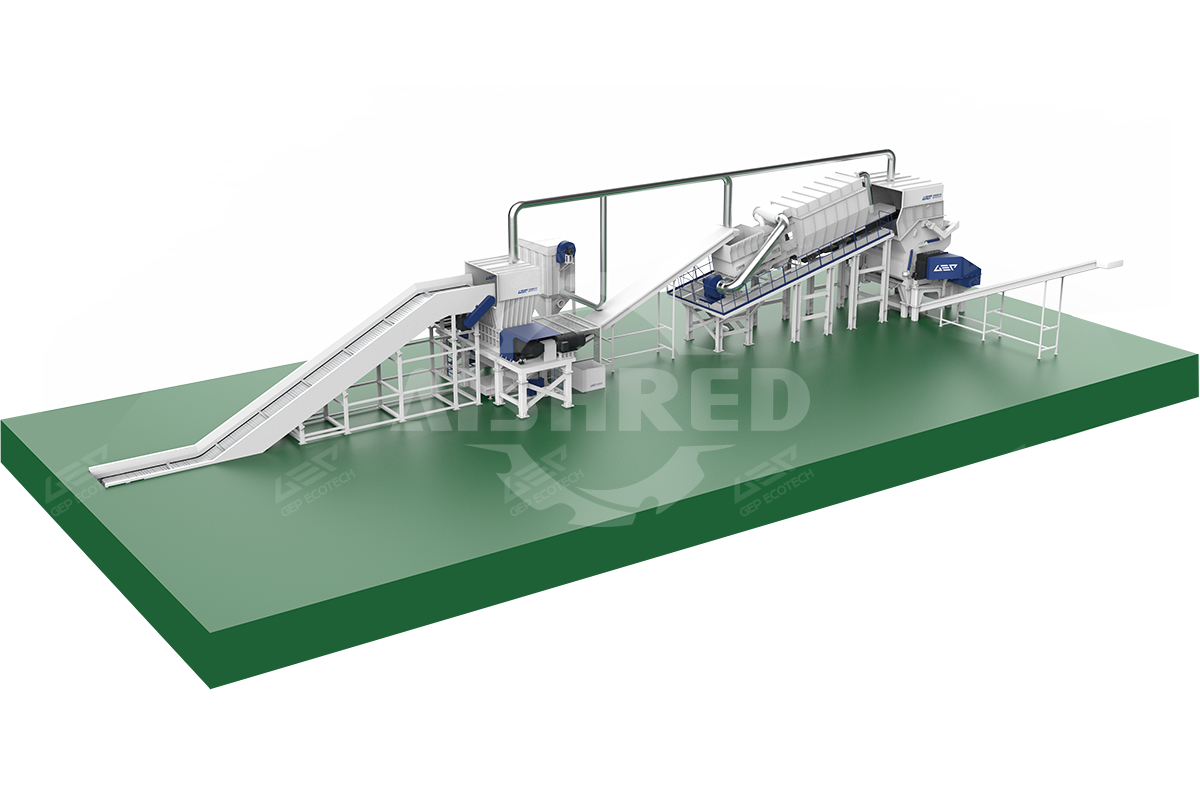

In biomass coupling, raw materials undergo pre-treatment processes such as shredding and drying before being mixed with coal powder in a specific ratio and fed into the boiler for combustion. The primary processing workflow is as follows:

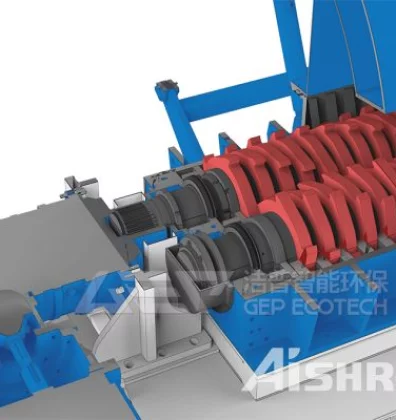

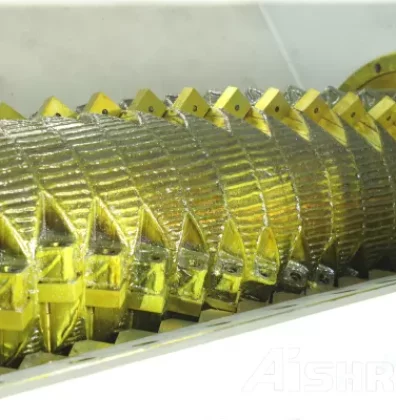

- Primary Shredding: The raw biomass materials are conveyed to a biomass shredder, which can quickly break down and disperse both bundled and loose biomass into smaller pieces.

- Magnetic Separation: The shredded materials then pass through a magnetic separation system to remove non-ferrous metals, ensuring purity and safety.

- Screening: After primary shredding and magnetic separation, the materials enter a screening system. This step removes heavy substances and other incombustible materials, streamlining the biomass for further processing.

- Fine Shredding: The screened materials are fed into fine shredding equipment, where they undergo secondary shredding. The output size is precisely controlled by a screen mesh to meet the requirements for biomass coupling.

If you have similar projects or are interested in exploring biomass coupling solutions, please feel free to contact us. We offer tailored services and comprehensive solutions to meet your specific needs.