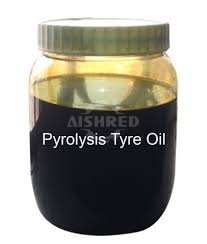

The oil produced from tire pyrolysis and refining is usually referred to as pyrolysis oil or cracking oil. It belongs to heavy oil and cannot be directly burned. It needs to be further processed before it can be safely and effectively used. The following are specific reasons and solutions:

1. Complex Composition

1) Impurities: Pyrolysis oil contains impurities such as sulfur, nitrogen, chlorine, etc. Direct combustion can produce harmful gases.

2) Instability: The chemical composition of pyrolysis oil is complex, and direct combustion may lead to incomplete combustion, producing black smoke and harmful substances.

2. Disposal Method

1) Refining: Removing impurities through processes such as distillation and filtration to improve the purity and stability of the oil.

2) Desulfurization: Using desulfurizers or catalysts to remove sulfides and reduce the production of sulfur dioxide during combustion.

3) Mixing: Mixing pyrolysis oil with diesel or other fuels to improve its combustion performance.

3. Application Fields

1) Industrial fuel: Processed pyrolysis oil can be used as fuel for industrial boilers, kilns, etc.

2) Power generation: Fuel used in power plants to provide thermal energy for power generation.

3) Chemical raw materials: used as raw materials for chemical production, further processed into other products.

4. Safety and Environmental Protection

1) Emission control: When using pyrolysis oil as fuel, corresponding emission control equipment should be equipped to reduce pollutant emissions.

2) Compliance: Ensure that the handling and use processes comply with local environmental regulations and standards.

GEP ECOTECH, as a Provincial “SRDI” (Specialized, Refinement, Differential and Innovation) Enterprise, has many years of experience and rich project cases in tire pyrolysis and oil refining. If you have any inquiries, please feel free to contact us at any time.