Demolition projects generate vast amounts of waste materials that need to be properly managed and disposed of. Traditional methods of handling demolition waste can be time-consuming, costly, and harmful to the environment. However, with the technological advancements in waste processing, the utilization of double-shaft shredders is emerging as a sustainable solution. In this article, we will delve into how double-shaft shredders efficiently process demolition waste to promote efficient waste management practices.

Versatile and Robust Design

Double-shaft shredders are engineered with a versatile and robust design, making them ideal for handling a wide range of materials found in demolition waste. These powerful machines can efficiently shred various materials, such as wood, concrete, metal, plastics, and more. The dual-shaft configuration ensures a controlled and uniform shredding process, resulting in consistent particle size reduction.

Efficient Size Reduction

Utilizing high-torque rotating shafts equipped with sharp blades, double-shaft shredders effectively break down bulky demolition waste into smaller, manageable pieces. The continuous shredding process guarantees a substantial reduction in waste volume, enabling better utilization of available space during transport and storage. Additionally, the shredded waste can be readily recycled or repurposed for other construction or manufacturing applications.

Enhanced Sorting and Separation

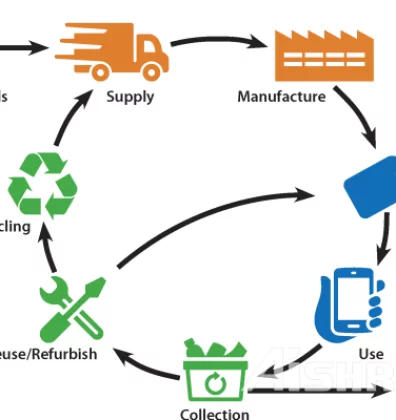

Double-shaft shredders facilitate material sorting and separation within the shredding chamber. By incorporating adjustable screens and sieves, these shredders allow for precise control over the desired output size and separation of different materials. This feature streamlines subsequent recycling processes, making it easier to extract valuable materials from the shredded waste, further promoting a circular economy.

Safety and Environmental Considerations

Double-shaft shredders are designed with safety features to protect operators and minimize environmental impact. Advanced systems, including overload protection, automatic shut-off, and foreign object detection, ensure safe and efficient operation. Additionally, these shredders efficiently reduce waste volume, minimizing the need for landfill space and reducing carbon emissions associated with transportation.

Cost-Effective Waste Management Solution

Implementing double-shaft shredders for processing demolition waste offers a cost-effective waste management solution. The efficient size reduction, enhanced sorting capabilities, and ability to recover valuable materials from the shredded waste contribute to overall cost savings. Moreover, the reduced reliance on traditional waste disposal methods leads to long-term cost efficiencies and a positive environmental footprint.

Double-shaft shredders have revolutionized the way demolition waste is processed, providing an efficient and sustainable solution for waste management. Their versatile design, efficient size reduction capabilities, enhanced sorting and separation features, and overall cost-effectiveness make them a valuable tool in the construction and waste management industries. By embracing this technology, we can minimize the environmental impact of demolition waste and promote a circular economy that prioritizes resource conservation and sustainability.