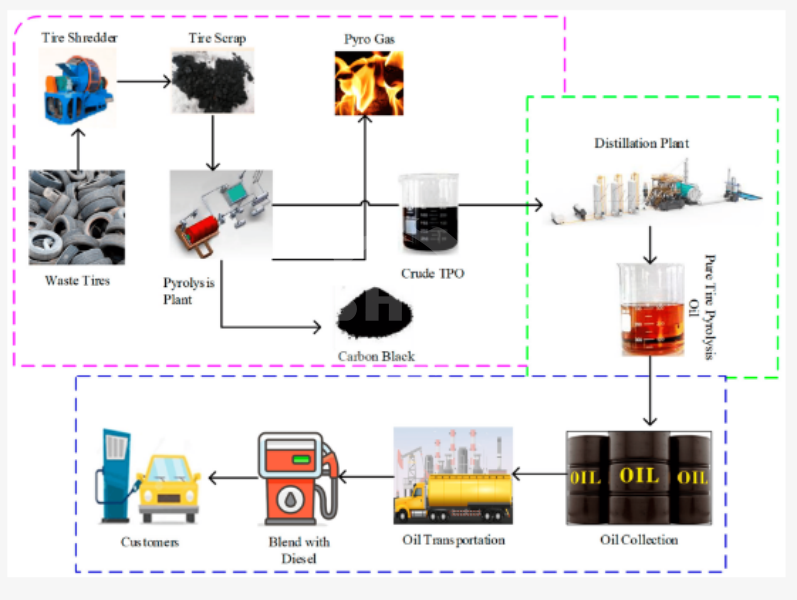

Tire pyrolysis and oil refining is a process of converting waste tires into valuable substances through pyrolysis technology. So what is the overall process like? Let's learn about it together, and see what GEP ECOTECH says.

Firstly, Pre-treatment

Remove metal parts, large debris, etc. from waste tires to prevent equipment damage and improve operational efficiency. For continuous production lines, it is also necessary to shred waste tires into rubber chips or grind them into rubber powder.

Secondly, Feeding

By manual or mechanical means such as screw feeders, hydraulic feeders, lifting winches, the pre-treated tires or rubber powder are fed into the pyrolysis furnace and the furnace door is closed to ensure high-temperature heating in a sealed environment.

Thirdly, Pyrolysis Reaction

Heating the pyrolysis furnace under anaerobic or hypoxic conditions, at a certain temperature and pressure, causes the rubber and organic matter in the tire to undergo pyrolysis. The general temperature control is between 160℃ and 700℃. If oil and gas are produced when the temperature reaches 160℃, the main oil production stage is between 200℃ and 300℃.

Fourth, Oil and Gas Recovery

The oil and gas produced by pyrolysis are buffered by a buffer tank to reduce flow rate and settle impurities, and then enter the condensation system, such as horizontal condenser, tubular condenser, condensing tower. Through circulating water cooling and other methods, the gaseous oil is converted into liquid to obtain tire pyrolysis oil.

Fifth, Solid Separation

The remaining solid substances from pyrolysis are mainly carbon black and steel wires. Carbon black can be discharged and collected through equipment such as screw conveyors, while steel wires are extracted, sorted, and bundled through tire bead wire puller for recycling and reuse.

Finally, Exhaust Gas Treatment

Non condensable combustible gases, after desulfurization, deodorization, and purification treatment, can be used as fuel for pyrolysis furnaces and returned for heating; The smoke generated by combustion needs to be treated by environmental protection equipment such as desulfurization and dust removal, and discharged after meeting the standards to ensure compliance with environmental requirements.

After reading about the general process of tire pyrolysis and refining, do you have any inquiries or questions about waste tire to pyrolysis system? Please just feel free to contact GEP ECOTECH at any time, and we will give you a feedback as soon as we can.