Tire pyrolysis oil refining has become increasingly popular due to its simplicity and high profitability. Many tire recycling companies are adopting or exploring this technology as it not only generates valuable oil from waste tires but also reduces environmental impact. Its flexibility to integrate seamlessly with existing recycling lines makes it an efficient choice for production expansion. Additionally, the process helps lower dependency on fossil fuels by creating alternative energy sources, aligning with global sustainability goals.

Price of Tire Pyrolysis Production Line

When it comes to tire pyrolysis oil refining systems, the cost is a major concern for both newcomers and experienced recyclers. However, the price can vary significantly depending on the system's configuration and capacity. To help you better understand, let’s explore the different types of pyrolysis systems and their general price ranges.

Batch-Type Pyrolysis System

The batch-type pyrolysis system is the go-to choice for most entry-level recyclers due to its straightforward operation. Its pyrolysis furnace can process whole tires without pre-treatment, producing one batch per day. The system's capacity largely depends on the furnace size, typically handling around 10 to 20 tons per batch.

The process includes four main steps:

- Feeding – Tires are loaded into the pyrolysis furnace.

- Pyrolysis – The furnace is heated for approximately 8–10 hours to break down the tires.

- Cooling – The system is cooled to safely handle the outputs.

- Residue Removal – Char and other by-products are removed.

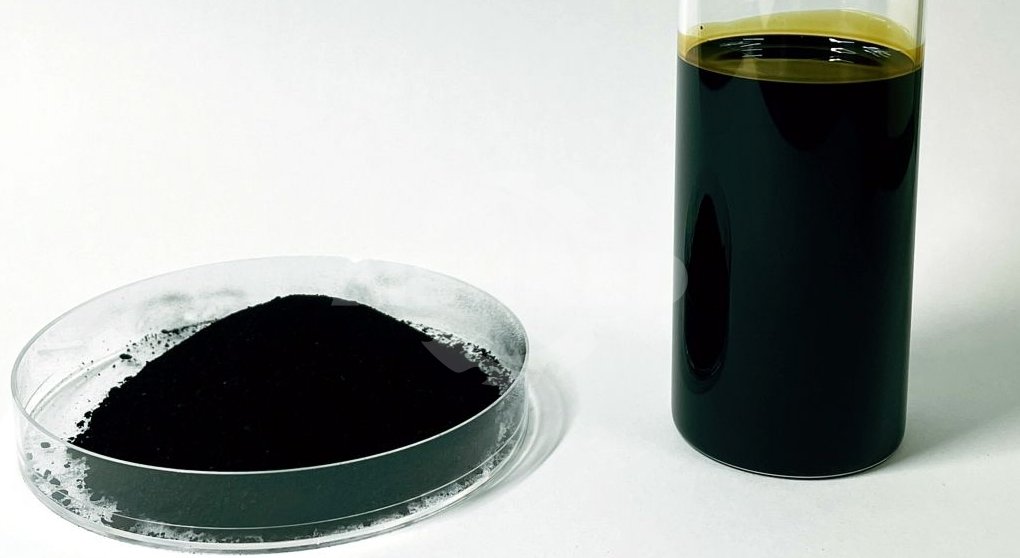

Batch systems typically achieve an oil yield of around 40%. Their simplicity, affordability, and ease of operation make them attractive for small-scale setups. However, the yield and equipment performance can vary based on the operator's expertise. Skilled operators can optimize oil output and minimize wear and tear on the machinery.

In terms of cost, a basic batch-type pyrolysis system can start as low as $20,000. However, more reliable systems from established manufacturers are generally priced around $50,000.

Continuous Pyrolysis System

The continuous pyrolysis system stands out for its ability to process materials and produce oil continuously, offering significantly higher efficiency compared to batch systems. With a starting capacity of around 30 tons per day—making it suitable for larger operations—it primarily uses rubber powder instead of whole tires as feedstock.

This system achieves an oil yield of over 50%, making it an excellent choice for high-volume production and maximizing resource utilization. Its continuous operation reduces downtime, ensuring consistent output and higher profitability. However, the upfront investment is considerably higher. A basic continuous pyrolysis system typically starts at $400,000. Additionally, since rubber powder is the required input, a tire pulverizing production line is also necessary, which adds to the overall cost.

Due to these factors, continuous systems are most often adopted by large recycling enterprises or those looking to scale up their operations significantly. Their efficiency, high oil yield, and integration with tire pulverizing lines make them a preferred choice for maximizing output and operational scale.

Energy Consumption

Tire pyrolysis systems are highly energy-efficient, as they use the oil and gas produced during the process as their main heat source, resulting in minimal electricity consumption. However, the continuous pyrolysis system includes a tire shredding and grinding stage, which requires several hundred kilowatts of power. This should be taken into account when designing the power supply to ensure adequate capacity for the entire system.

GEP ECOTECH Tire Pyrolysis Solutions

GEP ECOTECH offers efficient and cost-effective tire pyrolysis systems designed for both small and large-scale operations. Our systems deliver high oil yields, low energy consumption, and are easy to integrate into existing recycling lines. We provide full support from design to installation and maintenance.

Contact us today for a personalized quote and to learn how our solutions can help you turn waste tires into valuable resources while maximizing profitability.