For many plastic manufacturers, plastic lumps and purging waste are a real headache. These solid, irregular, and oversized chunks—generated during injection molding, extrusion purging, or machine clean-outs—are hard to manage and even harder to recycle without the right equipment.

Traditional granulators can’t handle these large, dense pieces efficiently. That’s where GEP ECOTECH’s specialized plastic lump shredders come in—turning difficult waste into valuable resources.

PP (Polypropylene) Lumps

Tailored Shredding Solutions: Choose What Fits Your Needs

We offer two main types of shredders for handling plastic lumps, blocks, and purging waste. Each is designed for different materials, throughput, and output goals.

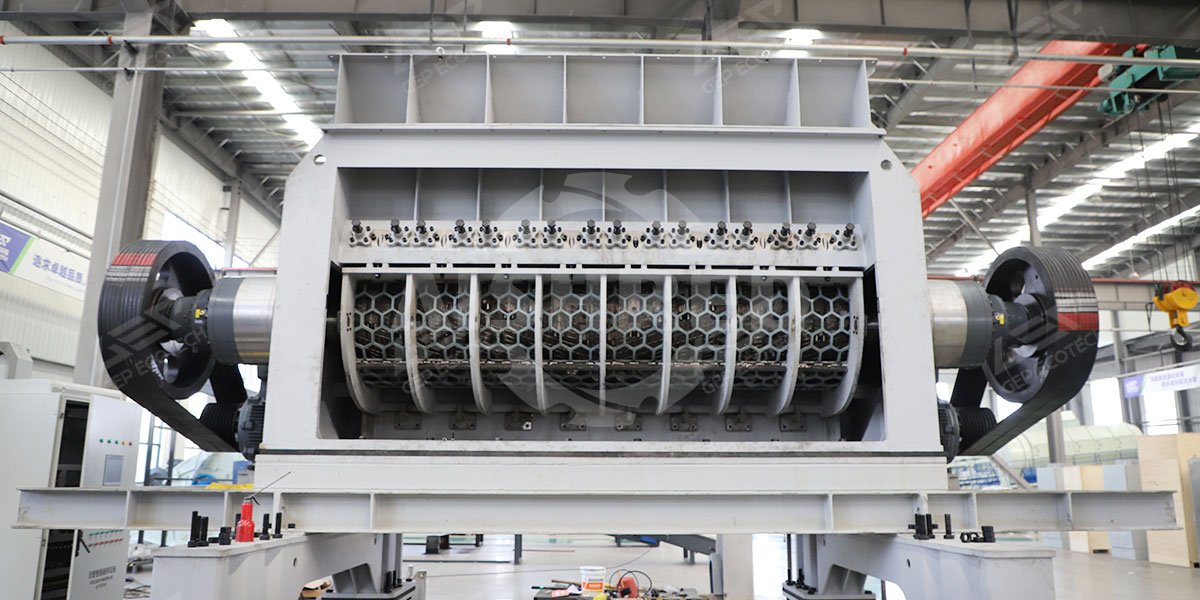

Dual-Shaft Shear Shredder

Heavy-duty performance for irregular and tough plastic lumps

- Twin shafts rotate at low speed and high torque, ideal for tearing through thick lumps and start-up purge blocks.

- Excellent for contaminated, mixed, or oversized materials that are too difficult for granulators.

- Simple, robust structure with low maintenance needs.

Typical applications

- Injection molding head blocks

- Start-up purge from extrusion lines

- Plastic chunks with metal or fiber reinforcement

- Processing before granulation or washing

Single-Shaft Shredder

Precision shredding for clean, homogenous plastic blocks

- Equipped with a hydraulic pusher and screen to control output size

- Delivers uniform chips that are easy to feed into pelletizing or compounding lines

- High efficiency for continuous recycling operations

Typical applications

- Clean purging plastic

- Uniform start-up waste

- High-quality recovery lines for pellet production

Key Features of Our Plastic Lump Shredders

- Durable and Wear-Resistant Blades – Specially treated steel blades for longer lifespan and reduced downtime

- Flexible Hopper Design – Tailored for large, awkward pieces of plastic

- Smart Control System – PLC-based automatic monitoring, load balancing, and overload protection

- Easy Maintenance – Quick access to blades and components

- Custom Output Size – Screens and configurations to match downstream needs

Our plastic lumps shredders are widely used in:

- Plastic product manufacturing plants

- Recycling companies

- Regrind production lines

- Compounding and pelletizing operations

- E-waste dismantling plants (for thick plastic casings)

Processing Injection Lumps in Malaysia

One of our clients in Southeast Asia operates a high-throughput recycling line that handles 1.2 tons per hour of PP injection molding lumps and purging blocks. They chose our GD6 dual-shaft shredder for its strong shearing ability, stable operation, and low energy consumption. The shredded material is cleaned and pelletized for reuse in non-critical molded parts.

Plastic Lumps Shredding Line

Don't let purging waste and oversized blocks slow down your recycling operations. Contact GEP ECOTECH today for a tailor-made shredding solution that delivers power, precision, and performance.