The traditional RDF (Refuse-Derived Fuel) production process mainly relies on heavy-duty single shaft shredders for shredding treatment, sometimes using double shaft shearing or primary shredding as pretreatment equipment to improve material processing efficiency. However, this process presents many challenges: the price of single shaft shredders from some world well-known manufacturers may reach as high as USD850,000, putting significant financial pressure on small and medium-sized enterprises in the initial investment stage; The power consumption for ton processing can reach 50 kW·h, which not only increases operating costs, but may also require additional procurement of high-capacity transformers to meet demand; In addition, wearable parts such as cutters wear out quickly and often require repair or replacement within a few days, thereby increasing maintenance costs. These factors limit the cost control and production efficiency of traditional process, affecting the long-term sustainable development of enterprises.

GEP ECOTECH has been engaged in RDF production research for many years, and our heavy-duty single shaft shredder has been applied in multiple RDF projects. We are constantly exploring more efficient solutions and have launched a new three-stage dual shaft RDF production line.

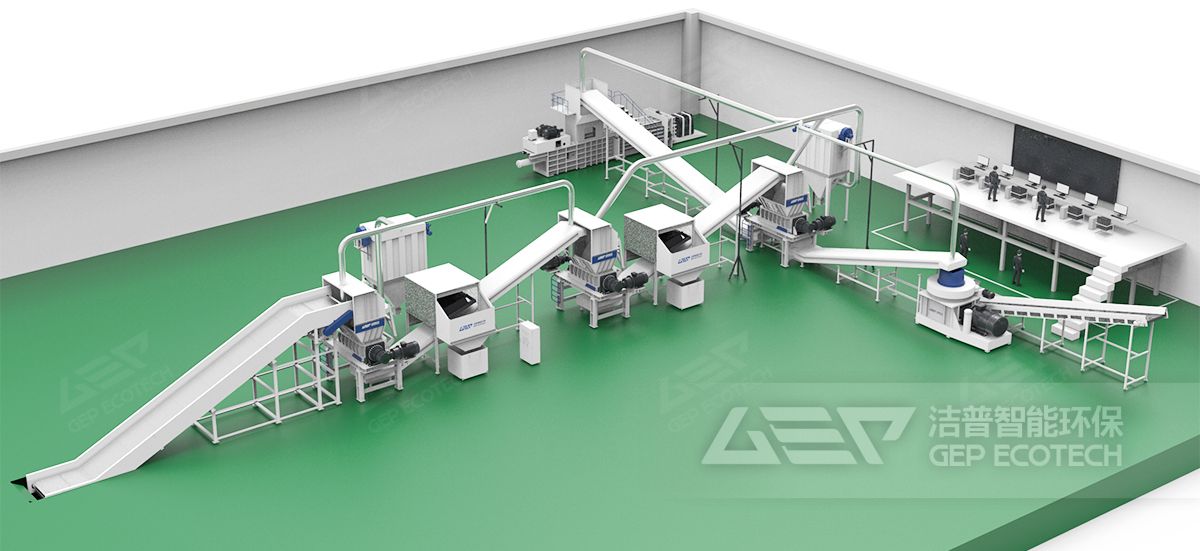

Three-Stage Dual-Shaft Shredding RDF Production Line

What is a three-stage dual shaft RDF production line

The three-stage dual-shaft shredding mechanism RDF production line is an efficient and modular waste treatment system specifically designed for producing RDF. Its core feature is the use of a three-stage dual-shaft shredder series process, which converts mixed waste (such as MSW, industrial waste) into RDF fuel with uniform size and stable calorific value through multi-stage shredding, screening, and sorting. This production line not only solves the high cost and energy consumption problems of traditional RDF preparation processes, but also provides a sustainable solution for waste resource recycling.

Characteristics of the production line

- Three stage progressive shredding: Through primary, intermediate, and fine shredding, the waste is gradually shredded to the target particle size, ensuring the high quality and consistency of RDF fuel. Compared to one-time shredding, it has lower energy consumption and higher efficiency.

- Dual shaft shredder: Adopting a dual shaft design, it has stronger shearing force and processing capacity, and can efficiently process waste with complex components.

- Modular design: The production line can be flexibly configured according to customer needs to adapt to projects of different scales and processing requirements.

- Efficient and energy-saving: By optimizing energy consumption design and extending the service life of wearable parts, operating costs are reduced and economic benefits are improved.

Sinoma Cement RDF Production Line Operation Status

Not long ago, the 100,000 ton per year waste textiles alternative fuel project designed and produced exclusively by GEP ECOTECH was officially put into operation in Jiangsu (a developed province in southeast China). In response to the strong entanglement and complex composition of waste textiles, GEP ECOTECH creatively adopts a three-stage dual-shaft shredding process to convert waste textiles into RDF, which is directly supplied to the cement kilns of a central enterprise—Sinoma Cement to achieve coal substitution.

The overall disposal process of the project is as follows: Loader feeding→ Chain plate conveyor → First-stage double shaft shredder GD12 (preliminary shredding) → Second-stage double shaft shredder GD12 (further shredding) → Magnetic separator (to remove ferrous metals) → Third-stage double shaft shredder GD12 (most discharge size around 10cm) → Hydraulic baler.

This solution has created significant benefits for the customer: The entire production line has a capacity of at least 15 tons/hour, which is significantly higher than the "dual shaft shredder+wind sifter+single shaft shredder" process, fully meeting the needs of large-scale production; Innovative use of three-stage differentiated cutter design, making the cutters more wear-resistant, saving maintenance time, and significantly reducing downtime losses; In addition, the significant reduction in power consumption for ton processing has saved customers a considerable amount of operating costs.

The material size after three-stage dual shaft shredding is relatively uniform (most under 10cm), which can be baled or mixed with other combustibles and pelletized by RDF pelleting to increase the calorific value. But it is not omnipotent either. The traditional “dual shaft shredder+wind sifter+single shaft shredder” process still has its potential market. For example, when strict requirements for the discharge size is required, the single shaft shredding solution would be adopted, which has a screen to control the discharge size. In practical applications, we will provide customized solutions based on the specific needs of our customers. Our engineering team can provide full technical support to ensure that the production line operates at its best.

With over a decade of experience in solid waste disposal, GEP ECOTECH can provide various RDF/SRF production line equipment for different materials, including industrial waste and MSW. Additionally, we offer TDF (Tire-Derived Fuel) and biomass pellet fuel production line equipment. If you have related needs, please feel free to contact us at any time.