Size reduction is defined as operations or processes which reduce the size of influent materials through division into two or more subunits. Size reduction of municipal solid wastes (often called shredding, grinding, or pulverizing) is a new concept, and much of the technology has been borrowed from the mining and rock-crushing industry. Because solid waste is a heterogeneous mixture(unlike rock), much of the technology is not directly transferable; and size reduction of solid waste has not always been efficient; however,as more solid waste systems have been built, the technoloqy of solid waste size reduction has been sianificantly advanced.

More than 2.01 billion tonnes of municipal solid waste are produced annually worldwide. Land areas suitable for land disposal near urban areas where the bulk of the solid waste is generated are becoming scarce and expensive. Open burning and open dumping have been outlawed in many areas because of pollution and health hazards. Incineration is becoming increasingly more expensive because of sophisticated pollution control equipment required to meet acceptable air and water quality standards. Current emphasis in solid waste management, therefore, has centered on both disposal of this great quantity of material and its utilization as a national resource. Because the quantities of solid waste produced each year are so great, the relatively high capitai costs of mechanical processing equipment can be amortized over large tonnages, and consequently the cost of processes such as shredding have become competitive with other solid waste management options. This in turn has permitted shredding to become an integral part of disposal and resource recovery systems.

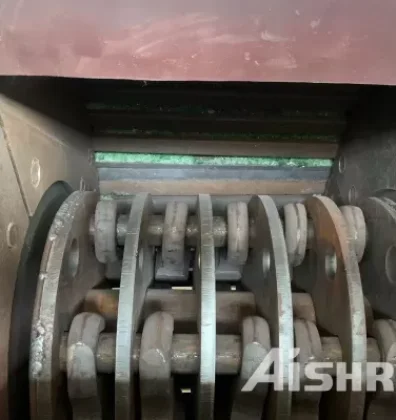

Shredding as an Integral Part of a Disposal System

Municipal solid waste generally has a low, but nonuniform bulk density. Size reduction increases the homogeneity and the bulk density. The process of size reduction yields a smaller range of particle sizes and thoroughly mixes the solid waste. The net result is that the waste can be easily compacted to a uniform density, and voids formed by bulky items are eliminated. The amount of reduction in bulk can vary depending on the final processing of the waste; however, landfill measurements have indicated that shredded waste placed in a landfill and compacted in a manner similar to unshredded waste can have the effective density increased 25 to 60 percent over that of unshredded sol id waste, depending on whether or not daily cover is requirpd.

It is the bulk reduction and mixing of the waste that gives size reduction its most promising potential for immediate application in land disposal technology. Solid waste that has been shredded and compacted has fewer voids than unshredded waste, has no objectionable odor when properly compacted, does not attract vermin, and has been used in landfill without a daily cover of soil. It is because of these advantages that a milled solid waste disposal site tends to be more saleable to the general public than a standard land disposal site.

Shredding can also fit into another disposal system variation, and that is, land disposal preceded by incineration. Shredders are sometimes used to reduce bulky wastes so that they may be fed into the incinerator combustion chamber and processed along with the nonshredded waste. Additionally, there are new incinerator combustion chamber designs, such as fluidized beds, spreader stokers, and suspension burners, that require shredded solid waste for certain feed characteristics, as wel1 as, rapid combustion characteristics.

Shredding has also been used in conjunction with solid waste baling. The bales were found to maintain relatively high density, after wire tying, with a relatively low compactive effort as compared to a scrap metal type baler using nonprocessed waste and no wire tying. Should market conditions warrant, fractions of the shredded waste (e.g. light combustibles, ferrous material, etc.) can be separated out prior to baling for disposal.

Shredding as an Integral Part of a Resource Recovery System

As was indicated in the preceding paragraph, solid waste disposal and resource recovery are neither mutually exclusive, nor independent. An increasing number of communities are looking to resource recovery to serve not only as a means of conservina resources s but also as a means of reducing the volume of solid waste for disposal. Shredding is a processing step that serves both resource recovery and disposal.

There are basically two forms of resource recovery being instituted in communities today. The first form is recovery of materials such as glass, paper or metals. The other is recovery of energy such as by pyrolysis (heating with limited oxygen to produce chemical by-products with fuel value) or by direct combustion of the light combustible portion of solid waste in power plant boilers along with fossil fuel. Many variations of both forms of resource recovery are facilitated by or directly require shredded solid waste as an input material. The reasons for this are:

- Ease of handling: Comnared to nonprocessed solid waste, shredded solid waste has a smaller range of particle size, is more uniform in density, and is a more homogeneous mixture5 thus permitting it to be easily handled and processed by mechanical equioment. The mechanical and chemical processes used by most recovery systems require separation of various components. This separation is easier and more efficient when particle size range is controlled. Sorting operations such as screening, air classification and magnetic separation can be optimized with respect to power requirements and efficiency of separation by shredding waste to designated particle size ranges. Shredding should be considered a "service" component of the system--!.e.9 it does not determine what the operating oarameters of the system are; it simoly adjusts the physical characteristics of the solid waste to optimize efficiency of the system.

- Improved burning characteristics: For energy recovery systems such as the one employed by the Union Electric facility in St. Louis, Missouri, shredding serves a twofold purpose. As stated above, it improves handling and separation characteristics for sorting into a light, fuel fraction and a heavy, chiefly inorganic fraction. The heavy fraction, in turn, can be further separated into ferrous, nonferrous metals, and glass fractions. The light, fuel fraction of shredded material is amenable to pneumatic feeding of the tangentially coal fi red boilers employed by Union Electric. Once inside the boiler, the solid waste particles are burned in suspension. Because these particles are relatively small (typically 1.5 inches or smaller), the chances of complete combustion of the waste are enhanced for the relatively short time that the waste is in suspension. Similarly, for some forms of heat recovery incinerators, such as fluidized bed furnaces, or spreader stoker furnaces, smal1 particle sizes can increase the surface area of the solid waste for better heat transfer characteristics. It should be pointed out, however, that for many standard grate incinerators shredded waste is actually detrimental to complete combustion, because too dense a fuel bed is formed to allow for complete combustion and mixing with process air.

Output particle size is normally specified in terms of the "nominal" particle size produced by a shredder. The nominal particle size is usually designated as a minimum percentage by weight of waste passing a given screen size, such as 80 or 90 percent passing a three inch square mesh screen.

The single, most important step in designing a sol id waste size reduction facility is to determine what functions the facility is expected to perform in the solid waste management system. This involves determining what input the shredder will receive and what output it is expected to deliver. Of the two--input and output--an exact definition of the output requirements is the more critical, for the output requirements determine the performance specifications of the size reduction facility-capacity in tons per hour, output particle size, composition, etc. The output particle size required will depend on what the next step in the solid waste management system is to be. For instance, if land disposal is the next step, a nominal particle size of three or four inches might be specified as the required output of the shredder. For the derivation of solid waste fuel for power plant application, a nominal particle size of 1.5 inches might be specified. For such an application,multi-stage shredding might be warranted, that is,the first stage shredding would produce a nominal particle size of four inches for the purpose of separation into a heavy fraction and a light fuel fraction. This light fuel fraction would in turn go through a second stage shredder with an output nominal particle size of 1.5 inches for feeding into a boiler. This multi-stage shredding would yield an overall shredding power and maintenance savings by not reducing the heavy fraction smaller than necessary. Similarly, other solid waste management systems wi 11 define particle size requirements where shredding is to be used. These particle size requirements should be carefully noted to avoid too coarse a shred which could adversely affect the remainder of the system or to avoid too fine of a shred which could adversely affect the system and unnecessarily increase power, maintenance and other operating costs.

GEP ECOTECH offers a comprehensive range of size reduction machines for solid waste treatment. Here you will find the right machine for every challenge, no matter how demanding. Simply filter according to your criteria and you will receive a solution perfectly matched to your industry and application.

You can find more information about shredding technology here: https://www.aishred.com/application/