Municipal Solid Waste (MSW) management is a pressing global challenge, and effective waste processing technologies are essential for sustainable waste disposal. In recent years, fine shredders have emerged as valuable assets in the secondary processing of MSW. This article explores the significance of fine shredders in enhancing MSW processing efficiency and promoting resource recovery.

Discharge Effect of Fine Shredder Crushing Municipal Solid Waste

Fine Shredders in MSW Processing

- Size Reduction for Enhanced Sorting: Fine shredders play a crucial role in reducing the size of MSW materials, making them more manageable for subsequent sorting processes. By breaking down bulky items into smaller particles, these shredders facilitate the extraction of valuable recyclables and organic materials.

- Increased Surface Area for Biological Treatment: The fine shredding process increases the surface area of organic waste, promoting more effective biological treatment. This is particularly beneficial for composting and anaerobic digestion, where smaller particles result in faster decomposition and higher biogas yields.

- Facilitating Material Recovery Facilities (MRFs): Fine shredders contribute to the efficiency of Material Recovery Facilities by preparing waste materials for sorting through conveyor belts and manual picking lines. The smaller, uniform particles produced by fine shredders make it easier to segregate different types of materials for recycling.

- Enhanced Combustion in Waste-to-Energy (WTE) Facilities: In waste-to-energy facilities, fine shredding improves the combustion process by creating a more uniform feedstock. This uniformity leads to better heat transfer and combustion efficiency, ultimately maximizing energy recovery from MSW.

- Reducing Landfill Volume and Environmental Impact: Fine shredders aid in reducing the volume of waste destined for landfills. Smaller particle sizes allow for denser packing, extending the lifespan of landfills and minimizing their environmental impact.

- Adaptability to Various Waste Streams: Fine shredders are versatile and can handle a wide range of waste materials, including plastics, paper, textiles, and organic waste. This adaptability makes them essential components in comprehensive MSW processing systems.

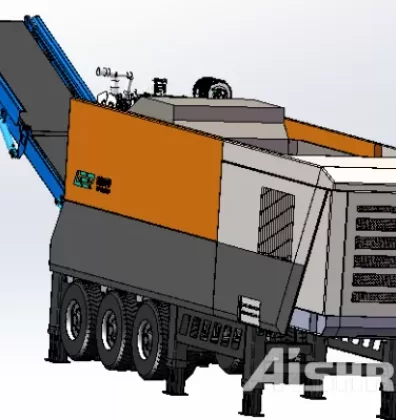

GEP ECOTECH's Fine Shredders for Enhanced MSW Secondary Processing

GEP ECOTECH's Fine Shredders stand as pioneering solutions in the realm of Municipal Solid Waste (MSW) management, driving enhanced secondary processing capabilities. With a commitment to environmental sustainability and cutting-edge technology, GEP ECOTECH's Fine Shredders play a crucial role in optimizing MSW processing efficiency. These state-of-the-art shredders, equipped with advanced size reduction capabilities, ensure precise material breakdown, facilitating seamless sorting and separation processes within Material Recovery Facilities (MRFs). Designed for versatility, these shredders adeptly handle diverse waste streams, including plastics, paper, textiles, and organics.

GEP ECOTECH's Fine Shredders in MSW to RDF Project

Fine shredders have become integral components in the secondary processing of MSW, offering numerous benefits for waste management and resource recovery. Their role in size reduction, facilitating sorting processes, and enhancing biological treatments positions them as key players in the pursuit of more sustainable and efficient waste processing systems. As advancements in technology continue, fine shredders are likely to evolve, further contributing to the optimization of MSW management practices and the promotion of a circular economy.