In the field of solid waste disposal, sorting equipment plays a significant role in many production lines, and the sorting effect and applicability of sorting equipment have always been a focus of attention. Especially for the more common wind selection equipment, many people are not very clear about its functions and scope of application, including how it performs in actual operation? Below, I will provide a detailed introduction to the wind selection equipment for everyone to have a clear understanding.

Scope of Application

Wind sifters are widely used in the processing of municipal solid waste, industrial waste, and other industries, effectively separating materials of different densities.

Sorting Effectiveness

The primary function of a wind sifter is to classify materials based on their density and particle size. It can separate lightweight materials (such as paper scraps, plastic bags, and films) from heavy materials (such as metals, glass, and stones), thereby achieving efficient material classification.

Advantages of Wind Sifter

- Flexible Airflow Adjustment: The main unit is controlled by a frequency converter, allowing flexible airflow adjustment according to the characteristics of the materials to ensure optimal sorting results.

- High Purity Sorting: The sorted materials have a high purity level, facilitating further processing in subsequent operations.

- Modular Design: The modular structure makes maintenance and component replacement easier, reducing equipment maintenance costs.

- Durability: With fewer wear-prone parts, the equipment has a long service life, reducing the frequency of equipment replacements.

- Wide Applicability: It can meet the sorting needs of materials with different properties and has a broad range of applications.

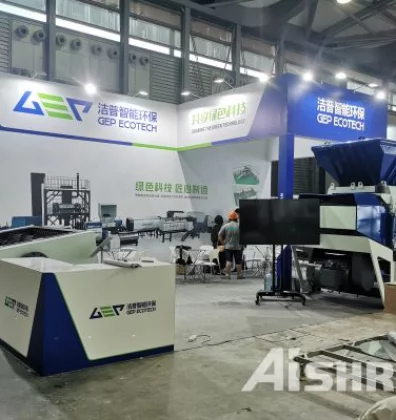

Welcome to contact GEP ECOTECH for detailed inquiries!