Lithium batteries, as an important means of modern energy storage, have been widely used in fields such as electric vehicles and consumer electronics. With the upgrading and end of service life of lithium batteries, a large number of waste lithium batteries need to be processed and recycled. As a key link in the recycling process, optimizing the performance of the lithium battery crushing system is of great significance for improving recycling efficiency, reducing costs, and minimizing environmental impact.

The current situation and challenges of lithium battery crushing system

- Equipment wear and energy consumption issues

- Security risks

- Resource recycling efficiency

Optimization strategy

- Equipment innovation and upgrading

- Process optimization

- Safety protection measures

- Intelligent control

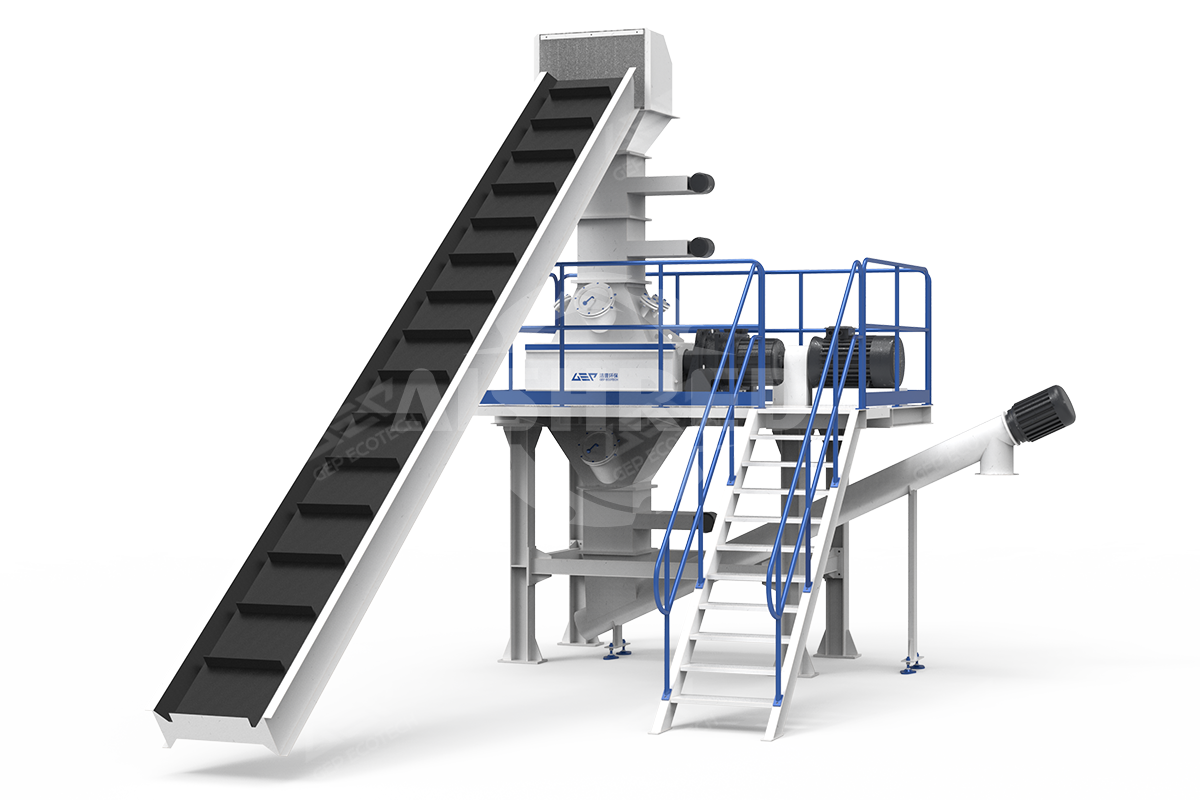

GEP ECOTECH Battery Crushing System

The process of GEP helping a leading domestic lithium battery recycling enterprise achieve perfect results in the practical application of lithium battery crushing systems is not achieved overnight. Firstly, both parties conducted in-depth research and analysis on the existing production processes and equipment, and identified the technical difficulties suitable for lithium battery crushing; Then, Jiepu designed a customized lithium battery crushing system based on the actual situation of different sites. The system adopts advanced processes such as conveying, sealing, crushing, and firefighting, which can adapt to the crushing of various batteries and achieve good discharge size, laying a good foundation for subsequent cracking and purification.

The lithium battery crushing system is a comprehensive project that requires multiple aspects such as equipment, process, safety, and intelligence. Through continuous technological innovation and management improvement, efficient and safe operation of the crushing system can be achieved, providing strong support for the discovery of the lithium battery recycling industry.