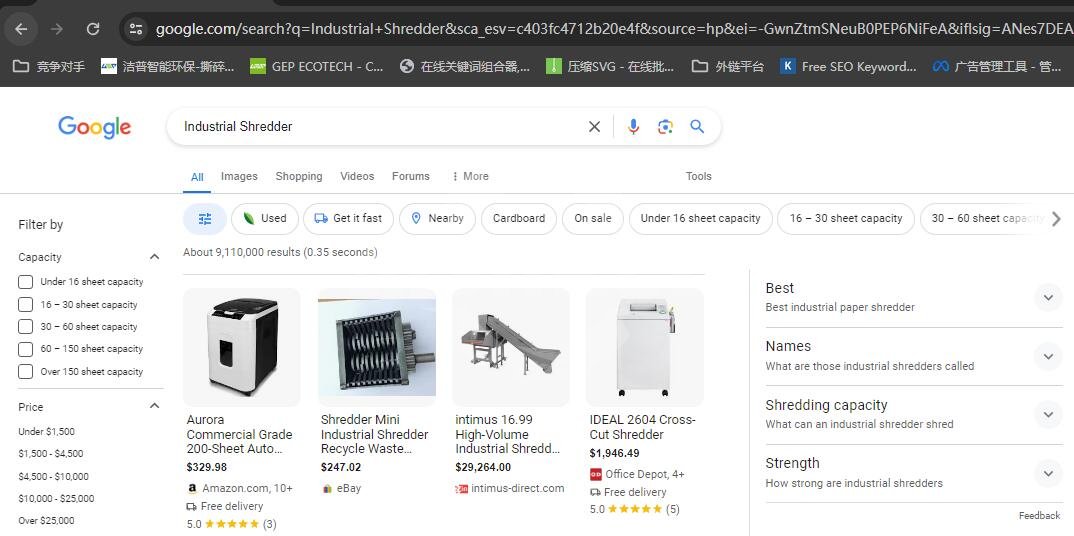

In our daily lives, paper shredders are ubiquitous office equipment. However, when discussing industrial shredders, many individuals encounter confusion. Have you ever searched for "industrial shredder" on a search engine, only to find results predominantly focused on office paper shredders? Perhaps you have even encountered platforms that conflate the two, exacerbating your confusion. Rest assured, you are not alone. Here, we will demystify industrial shredders and elucidate their true nature for you.

Google search results page confusing industrial shredders and paper shredders

Ⅰ. Concept

Industrial shredders are not intended for paper shredding. Rather, they are machines used to cut and tear various materials into small pieces. Due to their widespread use in industrial settings, they are referred to as "industrial shredders."

Ⅱ. Classification

There exist numerous types of industrial shredders, which can operate independently or collaboratively, serving various industries. They are classified based on different criteria:

Classification by Number of Shafts

- Single Shaft Shredder: Processes materials by rotating a single main shaft with blades.

- Dual Shaft Shredder: Utilizes two inwardly rotating main shafts to drive blade movement, suitable for processing diverse materials.

- Quad Shaft Shredder: Utilizes four main shafts arranged in a reverse trapezoidal layout, providing enhanced processing capabilities compared to dual shaft shredders.

Classification by Processing Stage

- Pre-shredder: Primarily used for initial processing of large-volume materials to achieve disintegration and reduce subsequent processing load.

- Shear Shredder: Utilizes shear force to process materials into strips approximately 5-15 cm long.

- Fine Shredder: Mainly used to process materials into smaller and consistent sizes to meet specific application requirements, such as RDF production lines and recycling needs.

Classification by Material Processed

- Municipal Solid Waste Shredder: Used for processing urban solid waste, typically for incineration, alternative fuels, or pre-treatment before landfilling.

- Industrial Waste Shredder: Used for processing industrial and commercial solid waste, suitable for incineration, co-processing with cement kilns, or volume reduction.

- Biomass Shredder: Used for processing agricultural and forestry waste, for biomass fuel preparation in biomass power plants or coal-biomass co-firing power plants.

- Tire Shredder: Used for crushing and recycling waste tires.

- Food Waste Shredder: Used for processing various wet waste.

Additionally, industrial shredders can be categorized into fixed and mobile equipment based on mobility. Different manufacturers may also classify their shredder product lines differently based on various criteria and market positioning. You can learn more about our industrial shredders and other products here.

Ⅲ. Applications

Industrial shredders have diverse applications, distinct from ordinary paper shredders. Here are several typical application scenarios:

Municipal Solid Waste Disposal

Urban activities generate a significant amount of municipal solid waste. Direct landfilling is discouraged, with methods such as incineration, co-processing with cement kilns, and mechanical biological treatment gaining prominence. Industrial shredders can shred waste materials and enhance sorting, increasing the recovery rate of recyclable materials, improving processing efficiency, and reducing costs.

Industrial and Commercial Waste Disposal

Industrial and commercial waste is relatively homogeneous. Industrial shredders can reduce the volume of difficult-to-handle materials, facilitating transportation and further processing. Converting combustible materials into SRF/RDF is a popular utilization method, with industrial shredders playing a pivotal role in this process.

Scrap Tire Disposal

Scrap tires can be recycled into rubber granules, rubber powder, tire-derived fuels, etc. Shredding tires is the initial step in recycling, with high-quality industrial shredders being essential in the recycling production line.

Data Destruction

While industrial shredders can also be used for data destruction, it differs significantly from paper shredders. Certain data storage media, such as mechanical hard drives, solid-state drives, and tapes, cannot be handled by paper shredders. Industrial shredders can easily destroy these items, ensuring confidentiality.

Ⅳ. FAQs

What is the typical price range for industrial shredders?

Determining the price range for industrial shredders is akin to pricing a car. There is a considerable price disparity between different brands and models. Similar to purchasing a car, individuals inquire about specific features rather than asking for a generalized price. Industrial shredders are akin to customized industrial machines, with prices contingent upon meeting unique requirements. As a preliminary estimate, industrial shredders we have sold range from over $10,000 to over $300,000.

How to choose the right industrial shredder?

Selecting the appropriate industrial shredder for specific tasks is akin to designing infrastructure projects. Numerous factors must be considered, including power supply, energy consumption, noise levels, site layout, and output planning. It is imperative to communicate extensively with professional suppliers to develop comprehensive plans aligned with requirements.

Which are some reputable industrial shredder manufacturers to recommend?

Partnering with reputable suppliers is paramount. Avoiding trading companies, which excel in managing supply chains but lack technical expertise, is advisable. Reliable suppliers prioritize brand value and offer transparent pricing, ensuring mutual benefit.

GEP ECOTECH Corporate Video Introduction

I recommend five high-quality industrial shredder manufacturers for your reference:

- GEP ECOTECH: A well-known leading industrial shredder manufacturer in China, dedicated to providing leading environmental solutions to global customers, with business footprints all over the world.

- SSI: A well-known industrial shredder manufacturer in the United States, established in 1980.

- Weima: A well-known industrial shredder manufacturer in the United Kingdom, established in 1986.

- Forrec: An industrial shredder manufacturer in Italy, established in 2007.

- Vecoplan: An American company originating from Germany, with rich experience in wood processing and plastic recycling.

Ⅴ. Conclusion

Industrial shredders are robust equipment that efficiently processes materials through mechanical force and power systems. They find applications across industrial production, resource recycling, volume reduction, and product destruction. Choosing an industrial shredder entails considerations beyond technical parameters, focusing on task completion and system efficiency.

Links: