As biomass-to-energy applications gain traction across Southeast Asia, efficient pretreatment of agricultural residues becomes essential. A recent inquiry from a Southeast Asian client highlights this trend. The client aims to process loose paddy straw and Napier grass, with a processing capacity of 5–10 tons per hour, maximum feed length of 2 meters, and a target discharge size around 100–200 mm, for further reduction before feeding into a biomass power plant. After initial communications, we GEP ECOTECH, came up with a double shaft shredding solution for the client.Why Shredding Is Important for Paddy Straw & Napier GrassRaw straw and napier grass are light, entangled, and difficult to handle directly. Their low bulk density and high moisture content make transport, storage, and combustion inefficient. Shredding helps reduce volume, untangle fibers, and prepare the material for drying, fine shredding, or direct biomass cofiring. It reduces volume, making transportation and storage more efficient. Shredded

As nations accelerate their transition to carbon neutrality, power plants are increasingly adopting biomass co-firing in Circulating Fluidized Bed (CFB) boilers to reduce coal dependency and decarbonize energy production. This shift not only aligns with global climate goals but also unlocks the potential of agricultural, forestry, and municipal waste as renewable fuel sources. However, the heterogeneous nature of biomass—varying in moisture, size, and calorific value—demands robust retrofitting of boiler systems and specialized preprocessing technologies. GEP ECOTECH, a pioneer in biomass and solid waste processing, delivers cutting-edge fuel preparation systems that ensure efficient, stable, and clean combustion in CFB boilers.Biomass Co-firing in Coal-fired Power PlantWhy Co-Fire Biomass in CFB Boilers?CFB boilers are uniquely suited for biomass co-firing due to their fuel flexibility and high combustion efficiency. By blending biomass with coal or other solid wastes, power plants can:Reduce GHG Emissions

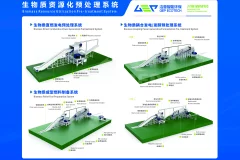

Biomass coupling is an innovative energy utilization method that combines biomass energy with traditional fossil fuels to generate electricity, thereby enhancing energy efficiency. Its unique technological advantages and environmental benefits have become a significant driver for the sustainable development of the energy sector. In biomass coupling, raw materials undergo pre-treatment processes such as crushing and drying before being mixed with coal powder in a specific ratio and fed into the boiler for combustion. The primary processing workflow is as follows:1. Shredding: The raw biomass materials are conveyed to a biomass shredder, which can quickly break down and disperse both bundled and loose biomass into smaller pieces.2. Magnetic Separation: The shredded materials then pass through a magnetic separation system to remove non-ferrous metals, ensuring purity and safety.3. Screening: After primary shredding and magnetic separation, the materials enter a screening system. This step removes heavy

Biomass Co-Firing Coal-Fired Power Units Coupled with Biomass Power Generation Pretreatment System

2024-12-11The biomass blending process is a technology that combusts biomass fuels in a mixture with traditional fossil fuels (e.g., coal, oil, etc.). This practice reduces dependence on fossil fuels and lowers greenhouse gas emissions, while also utilizing waste resources and contributing to environmental protection and sustainable development. gas emissions, while also utilizing waste resources, contributing to environmental protection and sustainable development. Pretreatment of biomass prior to blending is a critical step to ensure that biomass materials can be efficiently and stably blended with fossil fuels for combustion. The pre-treatment process usually includes crushing, drying, sieving, mixing, etc., with the aim of adjusting the biomass feedstock to a condition suitable for blending. The biomass blending pre-treatment system uses a variety of equipment to prepare the biomass fuel so that it is suitable for combustion with traditional fossil fuels (e.g., coal) or for individual high-efficiency energy

Indonesia, like many other countries, has an abundance of coal resources, with numerous coal-fired power plants across the nation. However, the environmental impact of unsustainable coal mining, such as air pollution and greenhouse gas emissions, has become a major concern. In response, the Indonesian government has set ambitious goals to reduce coal dependence and explore cleaner energy alternatives, including the retrofit of coal power plants for biomass cofiring, to help achieve its carbon neutrality targets.Many power companies in Indonesia have already taken proactive steps, developing retrofit plans and actively implementing biomass cofiring projects. For example, Indonesia Power replaced coal with biomass cofiring in 2023, reducing carbon dioxide emissions by 555,000 tons. Other power plants in Indonesia are also pushing forward with their biomass cofiring projects, and we have received numerous inquiries related to this transformation.GEP ECOTECH is dedicated to helping coal power plants achieve

In the global energy landscape, coal remains a dominant player, accounting for a significant portion of electricity generation. Despite its widespread use, coal-fired power plants face mounting criticism for their contribution to greenhouse gas emissions and climate change. As nations strive to meet carbon neutrality goals and adhere to international agreements, the urgency to transition away from traditional coal-fired energy has never been more critical.However, moving entirely away from coal-based power generation presents significant challenges due to its complexity and the time required for complete replacement. As a practical and immediate alternative, cofiring biomass with coal has emerged as an effective transitional solution. By blending biomass—a renewable and carbon-neutral fuel—with coal, power plants can significantly reduce greenhouse gas emissions without requiring extensive modifications to existing infrastructure.Biomass Cofiring MethodsCofiring sustainable biomass with coal can be achieved