Cone Crusher

2023-09-10Cone or gyratory crushers reduce material size through a compression method. During their operation, the main shaft drives the mantle in an eccentric motion, altering the distance between it and the liners, thereby achieving the crushing process. Cone crushers have the capability to process various medium to high-hardness rocks and ores, with an excellent reduction ratio. Consequently, they are typically used in the second and third stages of crushing circuits and sometimes even in the fourth or final stages of the crushing process.Cone crushers are known for their powerful performance in handling hard materials, making them widely used in the fine crushing processes of ores and tough aggregates. However, due to their compression-based crushing principle, they produce needle-like shaped output, which is less favored in certain industries. Additionally, cone crushers often face issues of bearing oil leakage, especially in lower-end equipment, as they typically operate under heavy loads. Furthermore, the

The Second Life of Concrete

2022-03-24Today, the processing of construction waste is becoming a encouraged industry. This not only reduces damage to the environment, but also creates considerable economic profits. Secondary crushed stone from concrete of demolished buildings turns out to be much cheaper than natural, since the energy consumption for its production is 8 times less. Currently, in a number of large cities of the world, obsolete reinforced concrete structures are being demolished. At the enterprises producing reinforced concrete products, a large number of substandard products have also accumulated during their work. This is the raw material for obtaining secondary crushed stone. Many companies have recognized the huge potential value of this, and have gradually accumulated technologies to process these wastes in large quantities and generate secondary crushed stone. They began to set up mobile or stationary construction and demolition waste disposal plants, expanding their business scope to the surrounding area.Real CaseZhong Yuan

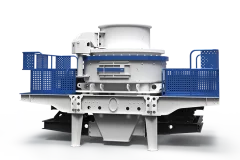

VSI Crusher

2022-03-03Vertical shaft impact crushers are another type of impact crushers. They reduce the size of materials by rapidly impacting them with a vertically positioned rotor. These machines typically come equipped with two motors to provide the necessary centrifugal force for the rotor. Combined with a unique crushing chamber, they can crush materials into very small sizes while achieving excellent particle shapes. Vertical shaft impact crushers are commonly employed in the final stage of the crushing circuit and find extensive use in aggregate and mining applications. They have garnered the moniker "sand-making machines" due to their pivotal role in the production of manufactured sand.Vertical shaft impact crushers operate by driving the rotors to rotate at high speed through central cantilever shaft. Imbalances in centrifugal forces can lead to abnormal equipment vibrations and damage to the support structures. GEP ECOTECH VSI crushers are multi-purpose crushing equipment that allows for flexible combinations of

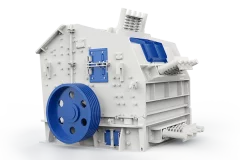

Impact Crusher

2022-03-03Horizontal shaft impact crushers (impact crushers for short) utilize horizontal rotors to strike stones at high speeds, reducing their sizes. The materials produced by impact crushers take on cubic shapes, which are believed to enhance the strength of concrete, making them ideal machines in the aggregate and recycling industry.The greatest challenge faced by impact crushers arises from the high-speed movement of the rotor. Imbalanced forces can result in abnormal vibrations in the equipment. If coupled with poorly manufactured bearings, bearing seats, and machine bodies, it can potentially lead to catastrophic accidents.GEP ECOTECH impact crushers are meticulously designed for safety, stability, and high throughput, offering a choice between two-chamber and three-chamber models. Their bodies are crafted from high-quality raw materials and undergo advanced processing and heat treatment processes to ensure exceptional impact resistance. The expanded feed inlet design enhances the crushing ratio, while the

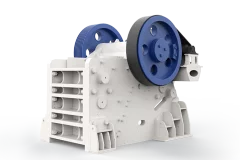

Jaw Crusher

2022-03-03Jaw crushers, as traditional and continually popular pieces of equipment, find wide applications in the mining, aggregate, and construction industries. They are commonlyused for the primary crushing of materials such as rocks, ores, and discarded concrete. Their operational principle is exceedingly simple, akin to the compression process observed in animal jaws, where they crush materials into smaller sizes. After over a century of development, jaw crushers remain highly favored, owing to their straightforward structures that ensure stable operation and ease of maintenance.As one of the most mature industrial crushing equipment, many companies claim that their equipment boasts top-notch performance. However, in practice, they still encounter numerous issues, such as eccentric shaft bending or fracturing, overheating of bearings, abnormal wear or even breakage of jaw plates, and rod fractures, among others.GEP ECOTECH jaw crushers help businesses establish consistently stable crushing production lines,