5-gallon paint buckets are a common sight in home renovations and industrial projects. While these buckets are sturdy and durable, they eventually reach the end of their lifecycle. Disposing of these large, specialized containers presents a significant environmental challenge.Why Recycle Paint Buckets?Paint buckets are typically made of metal or plastic, both of which have high recycling value. Metal buckets are shredded, compressed, and treated with heat to remove paint residues, then sent to smelting for reuse. Plastic buckets go through a similar process, where they are shredded, cleaned, and pelletized to create recycled plastic products.Efficient Shredding for Effective RecyclingCrushing or Shredding is a critical step in the recycling process. High-quality shredding equipment ensures that these materials are properly broken down for further processing. GEP ECOTECH offers a variety of shredding machines, including dual-shaft, four-shaft, and single-shaft models, to meet different recycling needs.

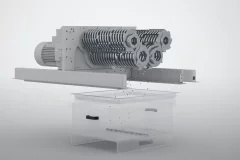

4 Shaft Steel Drum Shredder

2024-01-08Steel drums, commonly used in industrial settings for storage and transportation, play a vital role in various industries. However, after their life cycle, these drums often need to be recycled or repurposed, which calls for efficient shredding processes. The utilization of a four-shaft steel drum shredder becomes crucial in this regard.Why is Shredding Steel Drums Essential in Recycling?Steel drums, due to their durable and robust nature, can be challenging to manage during recycling. Shredding these drums into smaller components is necessary for several reasons:Volume Reduction: Shredding reduces the volume of steel drums, making them more manageable for transportation and further processing in recycling facilities.Material Handling: Smaller shredded components ease the handling of steel drums, ensuring a more efficient recycling process.Resource Recovery: Breaking down steel drums into smaller pieces allows for the recovery of valuable steel materials, facilitating their reuse in manufacturing.Advantages

In the world of waste recycling, plastic drums pose a significant challenge due to their size, durability, and potential environmental impact. To address this issue, plastic drum shredder machines have emerged as essential equipment in recycling facilities worldwide. This article explores the various types of commonly used plastic drum shredder machines, conducts an economic analysis of their benefits, and highlights the advantages of GEP ECOTECH equipment in this context.Common Types of Plastic Drum Shredder MachinesSingle-Shaft Plastic Drum Shredders: These machines feature a single rotating shaft with sharp blades or hammers that effectively shred plastic drums into smaller pieces.Dual-Shaft Plastic Drum Shredders: Dual-shaft shredders are designed with two interlocking shafts equipped with blades. This configuration enhances shredding efficiency and is ideal for handling thicker or heavier plastic drums. They are known for their versatility, making them suitable for various drum sizes and materials.

Drum Crushing Machine Sale in Qatar

2023-08-09Qatar, a rapidly developing country in the Middle East, is witnessing significant growth in various industries, accompanied by increased waste generation. Proper waste management has become a priority to ensure environmental sustainability. As part of this effort, the introduction of drum crushing machines for sale in Qatar is gaining momentum, offering an efficient solution for managing and recycling large drums and containers.Overview of the drum crushing machineA drum crushing machine is a specialized device designed to crush and compress empty or partially filled drums, reducing their size and facilitating easier transportation and recycling. These machines typically come in various sizes and configurations to handle different types and sizes of drums. They are equipped with powerful hydraulic systems, robust crushing mechanisms, and safety features to ensure effective and safe operation.Benefits of Drum Crushing MachinesThe utilization of drum crushing machines in Qatar offers several advantages:Space

Waste oil drums mainly refers to various IBC tank, gasoline containers, paint drums and other iron metal barrels. Waste oil drums are the most common liquid storage container. After the materials are used up, the waste oil drum contains various hazardous wastes. Do not dispose at will. Some enterprises or individuals dispose of abandoned oil barrels and IBC tanks at will after using up oil or sulfuric acid, this is illegal in most countries. Utilization value of waste oil drumsAll waste oil drums are pressed and formed by high quality sheet metal, which has high recycling value. Scrap iron can be recycled and smelted twice for use by crushing and shredding.Recycling of waste oil drumsVarious oil drums are widely used around the world. Oil drums have the characteristics of simple manufacturing process, low cost, simple structure, and good sealing performance. By using paint coating and anticorrosive technology, they can be used as an irreplaceable container. However, the materials stored in the oil barrel are

The storage of chemical solvents is generally done in special plastic drums, also called chemical drums, the more common ones on the market are the big blue drums. Plastic drums are stable in nature and do not affect the stability of the stored solvents, they also have a good isolation effect on all types of corrosion and toxicity, and are therefore widely used in the chemical industry. The iconic big blue drums in particular, with their better shading properties, are used particularly often. This has also resulted in what we are used to calling the big blue barrel crushing process when dealing with used chemical barrels. The big blue drums can be divided into hazardous solid waste and ordinary plastic drums according to their use. In addition to the big blue drums used to store hazardous chemical solvents, other storage of harmless items are harmless ordinary plastic drums, and their recycling treatment is naturally different. When crushed, ordinary plastic drums only need to be shredded by shredders, and