Recovering hazardous metals from waste is a critical step in mitigating environmental and health risks while reclaiming valuable resources. Several technologies are commonly employed for this purpose, including high-temperature metals recovery, retorting, secondary smelting, ion exchange, and acid leaching. These methods address specific types of hazardous metals, ensuring efficient separation and recovery.High-Temperature Metals Recovery HTMR is designed to extract hazardous metals like cadmium, chromium, lead, nickel, and zinc from waste materials. This thermochemical process involves heating waste at high temperatures using chemical agents such as carbon, limestone, and silica. The metals volatilize or melt, allowing them to be recovered in metallic or oxide forms.The process includes multiple stages: mixing, high-temperature treatment, product collection, and residual management. However, separating volatile metals like arsenic or antimony can be challenging and may affect the quality of recovered

Many people are looking for hazardous waste disposal companies or hazardous waste disposal sites near them. GEP ECOTECH has compiled a list of companies across the United States that can handle hazardous waste. You can quickly find hazardous waste disposal service providers in your corresponding city.This list has been compiled from publicly available websites and databases, to serve as a reference for those seeking hazardous waste treatment facilities. We strive to keep the information updated; however, we do not guarantee its accuracy, completeness, or timeliness. Users are encouraged to independently verify the information and directly contact the listed facilities to confirm their credentials and services.If you identify errors or prefer your facility not to be included in this directory, please contact us, and we will address your concerns promptly.Site IDSite NameCity, StateAK6210022426US ARMY GARRISON FORT WAINWRIGHTFORT WAINWRIGHT, AKAK8570028649JOINT BASE ELMENDORF-RICHARDSON (JBER)JBER, AKAK96903307

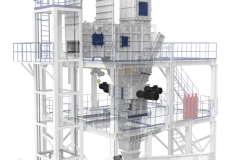

Closed Shredding System

2023-09-02Closed Shredding Systems (CSS) are designed forthe secure handling of hazardous waste, presenting a multi-tiered structure. They consist of modules such as feeding, shredding, safety, and control. CSS combine the safety of the shredding-mixing-pumping (SMP) system with the flexibility of individual shredding, making them suitable for a wider range of materials, with greater capacity and providing more options for subsequent processes.Given the intricacy of the system and the added safety features, closed shredding systems usually experience a more modest throughput. The complete system demonstrates high integration, handling intricate materials and operating frequently on a 24/7 basis. These requirements demand not only robust stability from the equipment but also impose substantial demands on the overall design capabilities of the manufacturers.GEP ECOTECH Closed Shredding Systems are specifically crafted to tackle the demanding task of hazardous waste disposal in challenging environments.Their safety and

Hazardous Waste Processing

2022-03-03Hazardous waste is a variety of corrosive, toxic, flammable, reactive or infectious waste that must be rendered harmless before it can be subsequently sterilised, recycled, landfilled or incinerated. The GEP ECOTECH shredding technology safely treats hazardous waste, including industrial waste, medical waste, radioactive waste, hospital waste, flammable packaging, etc.GEP ECOTECH can design different crushing solutions for different types of hazardous waste to meet the requirements of environmental and operator protection and different regional hazardous waste disposal standards. For example, the use of fire detection, automatic fire extinguishing devices, explosion-proof motors and corresponding control systems enable the crushing of flammable materials such as paint and chemical drums.Depending on the characteristics of the site, we have a choice of flat-bed and floor-mounted solutions, and GEP ECOTECH can provide a remote monitoring system for hazardous waste disposal applications, allowing for timely