Medical waste disposal is a critical challenge for healthcare facilities worldwide. Traditional methods—often manual, inefficient, and space-consuming—struggle to balance safety, compliance, and operational efficiency. These outdated approaches expose workers to biohazards, lack scalability, and fail to meet strict environmental standards.GEP ECOTECH’s Integrated Medical Waste Shredding & Sterilization System offers a smarter solution. Designed for high-throughput operations, it combines precision shredding with sodium hydroxide (NaOH) chemical disinfection, transforming hazardous waste into pre-treated, compliant material. Whether handling sharps, plastics, textiles, or mixed medical waste, our system ensures safe and adaptable processing, seamlessly integrating with incineration, autoclaving, or landfill disposal workflows.How It WorksFrom intake to final packaging, every stage is engineered for safety, efficiency, and compliance:1. Smart Feeding & Pre-SterilizationWaste is loaded via a bucket elevator

Oily rags are a hazardous waste, proper disposal of oily rags is essential for industrial safety and compliance. Depending on the volume of oily rags generated, different shredding solutions may be appropriate. This article introduces two types of oily rag shredder machines available for sale: the dual-shaft linear shredder for small-scale disposal and the enclosed shredding system for large-scale disposal.Dual-Shaft Linear Shredder: For Small-Scale DisposalFor facilities generating moderate amounts of oily rags, the dual-shaft linear shredder offers an efficient, compact solution.Key Features:Compact Design: Fits in limited spaces.Robust Construction: Ensures durability.Efficient Shredding: Two powerful shafts cut through rags effectively.Advantages:Cost-Effective: Affordable for small-scale operations.Ease of Use: Simple controls and low maintenance.Environmental Compliance: Proper disposal of oily rags.Enclosed Shredding System: For Large-Scale DisposalFor larger facilities producing significant volumes

Against the backdrop of the rapid development of modern industry, the generation of hazardous wastes has shown an explosive growth trend. These hazardous wastes are not only diverse, but also complex in nature, covering a wide range of hazardous characteristics such as radioactivity, infectiousness, corrosiveness, flammability and explosiveness, chemical reactivity and toxicity. In the face of this challenge, the hazardous waste disposal industry is ushering in unprecedented development opportunities, especially in the field of environmentally sound disposal.Hazardous wastes that are not properly disposed of will not only seriously damage the ecological environment, but also pose a potential threat to public health. In view of this, environmentally sound treatment technology has emerged as a key link in hazardous waste management. Among them, shredding treatment, as the initial step of environmentally sound treatment, is crucial for reducing the volume of waste and enhancing the efficiency of subsequent

Solid radioactive waste (SRW) poses significant challenges in terms of its safe management and disposal. To address these challenges, advanced shredder technology has emerged as a crucial tool for grinding and homogenizing SRW.Understanding Solid Radioactive Waste (SRW)SRW encompasses various materials contaminated with radioactive substances, such as protective clothing, tools, and equipment used in nuclear facilities. Proper management of SRW is essential to prevent environmental contamination and protect public health. However, the heterogeneous nature of SRW complicates traditional disposal methods, necessitating specialized treatment approaches.The Significance of Shredder TechnologyShredder technology plays a pivotal role in the treatment of solid radioactive waste by facilitating its grinding and homogenization. Unlike conventional methods, shredders are designed to break down SRW into smaller, uniform particles, which enhances subsequent treatment processes. This technology ensures efficient

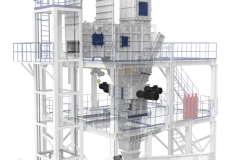

Closed Shredding System

2023-09-02Closed Shredding Systems (CSS) are designed forthe secure handling of hazardous waste, presenting a multi-tiered structure. They consist of modules such as feeding, shredding, safety, and control. CSS combine the safety of the shredding-mixing-pumping (SMP) system with the flexibility of individual shredding, making them suitable for a wider range of materials, with greater capacity and providing more options for subsequent processes.Given the intricacy of the system and the added safety features, closed shredding systems usually experience a more modest throughput. The complete system demonstrates high integration, handling intricate materials and operating frequently on a 24/7 basis. These requirements demand not only robust stability from the equipment but also impose substantial demands on the overall design capabilities of the manufacturers.GEP ECOTECH Closed Shredding Systems are specifically crafted to tackle the demanding task of hazardous waste disposal in challenging environments.Their safety and

With the continuous development of modern industry, the number of various hazardous wastes is increasing, and a variety of hazardous wastes have a variety of dangerous characteristics, including radioactive, infectious, corrosive, flammable and explosive, chemical reactive and toxic, hazardous waste disposal industry ushered in a period of rapid growth. Data show that the existing capacity of hazardous waste is mainly for comprehensive utilization of resources, and the capacity gap of harmless disposal of hazardous waste in China alone is about 20 million tons/year. If hazardous waste is not properly disposed and managed, it can easily pollute the environment and seriously affect human health and the ecological environment. This kind of hazardous waste harmless treatment has been widely used, hazardous waste harmless treatment in the beginning is shredding treatment, for example: IBC ton drums, 200L iron drums, plastic drums, ton bags, paint drums broken to reduce the volume, easy to follow the treatment,

Hazardous Waste Processing

2022-03-03Hazardous waste is a variety of corrosive, toxic, flammable, reactive or infectious waste that must be rendered harmless before it can be subsequently sterilised, recycled, landfilled or incinerated. The GEP ECOTECH shredding technology safely treats hazardous waste, including industrial waste, medical waste, radioactive waste, hospital waste, flammable packaging, etc.GEP ECOTECH can design different crushing solutions for different types of hazardous waste to meet the requirements of environmental and operator protection and different regional hazardous waste disposal standards. For example, the use of fire detection, automatic fire extinguishing devices, explosion-proof motors and corresponding control systems enable the crushing of flammable materials such as paint and chemical drums.Depending on the characteristics of the site, we have a choice of flat-bed and floor-mounted solutions, and GEP ECOTECH can provide a remote monitoring system for hazardous waste disposal applications, allowing for timely