Hammer Shredder

2024-10-08Hammer shredders, also known as hammer mills, are powerful and versatile machines widely used in the recycling industry for efficiently reducing various materials, particularly waste metals, into smaller, manageable pieces. With their high horsepower and large throughput capacity, hammer shredders are among the most commonly used equipment in waste recycling plants and metal recovery facilities. While they excel at processing loose materials, hammer shredders are not suitable for compacted waste, for which GEP ECOTECH's heavy-duty debalers are recommended for pre-processing.GEP ECOTECH's heavy-duty hammer shredders are high-performance solutions designed to meet the demanding needs of recycling operations. Their rugged design and powerful capabilities make them ideal for handling large volumes of difficult materials, including automobile shells, white goods, and both ferrous and non-ferrous metals. These machines are built for continuous operation with minimal downtime, providing cost-effective and reliable

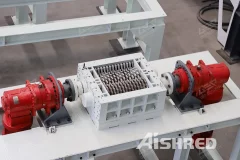

Recently, we received exciting news from our South Korean customer: the GD9Q dual-shaft shredder we supplied has been officially put into operation for scrap metal shredding.The customer, a prominent metal recycling company, handles a variety of scrap metals, including copper-clad laminate, circuit boards, copper-coated steel waste, and copper shavings. They use our GD9Q shear shredder to reduce these materials into pieces of about 10 cm for further processing.The GD9Q is an enhanced version of the GD9, specifically designed to deliver greater shearing force and durability for demanding applications. The installation process was supported by GEP ECOTECH’s technical team, ensuring a smooth and efficient setup.This project is one of the many successful metal recycling projects recently executed by GEP ECOTECH. In the current global economic downturn, many environmental projects dependent on government investments or subsidies have been delayed or canceled. However, metal recycling remains a lucrative

A scrap metal crusher, also known as a scrap metal granulator or metal shredder, is a device designed to reduce metal waste into small pieces for easier transport and recycling. Learn more about the criteria for purchasing a scrap metal crusher and discover the features and advantages of GEP ECOTECH scrap metal crushers

The price of an aluminum blocks shredding machine can vary widely depending on several factors, including the machine's specifications, brand, capacity, and whether it's new or used. Additionally, prices can vary from one region or country to another. To give you a rough estimate, I can provide a general price range based on common types of industrial shredders:Small-Scale Shredders (Low Capacity)Small shredders designed for low-capacity operations can range from $1,000 to $10,000 or more, depending on their features and quality.Medium-Scale Shredders (Moderate Capacity)Medium-sized shredders with a higher capacity typically range from $10,000 to $20,000, again depending on various factors.Large-Scale Shredders (High Capacity)Large industrial shredders capable of processing substantial amounts of material can cost anywhere from $20,000 to $100,000 or more, depending on capacity and features.GEP ECOTECH Single Shaft Aluminum Blocks Shredding Machine Specialized Shredders (Custom-Built)Custom-built shredding

When it comes to metal processing and waste management, the Hammermill Shredder is an essential piece of equipment. It is widely used for shredding discarded metal materials such as automotive wreckage, discarded electronic devices, and other metal scraps into smaller particles for further recycling or disposal.Working Principle of the Hammermill ShredderThe Hammermill Shredder operates based on a set of rotating hammers that crush metal materials at high speeds. It shreds metal waste into smaller particles through impact and shear forces. The primary function of a Hammermill Shredder is to reduce large metal pieces into smaller, manageable fragments. It is particularly effective in breaking down bulky metal waste, such as automotive parts or appliances, into smaller particles. Hammermill Shredders typically have a single rotor with multiple hammers mounted on it. The hammers strike the metal waste as it passes through, resulting in fragmentation. Hammermill Shredders are commonly used in the initial stages

UBC stands for Used Beverage Cans, and as the name suggests, it primarily consists of aluminum beverage containers that have been consumed and discarded by consumers. These cans are commonly used for packaging various beverages, including cocal, soda, beer, and energy drinks. UBC originates from households, commercial establishments, and public spaces, where people consume these beverages and then empty cans are collected by recycler.The recycling value of UBC is substantial and multifaceted. Aluminum, the primary metal in UBC, is highly sought after in the recycling industry for several reasons. Firstly, recycling aluminum requires significantly less energy compared to producing new aluminum from raw materials. This energy efficiency translates into reduced greenhouse gas emissions and conserves valuable resources. Secondly, aluminum retains its quality and properties even after multiple recycling cycles, making it an ideal material for sustainable manufacturing. Lastly, the recycling of UBC reduces the

Metal Shredders for Sale in South Africa

2023-12-28Metal shredders in South Africa have become instrumental in advancing the recycling industry by efficiently processing and recycling various types of metal scrap. These machines play a crucial role in transforming discarded metal materials into reusable resources, contributing to sustainable waste management and resource conservation efforts.Usage of Metal Shredders in South AfricaThe utilization of metal shredders in South Africa has gained momentum owing to their effectiveness in handling diverse metal scrap materials. These machines are extensively used in:Scrap Yards and Recycling Facilities: Metal shredders are prominently employed in scrap yards and recycling facilities to process and recycle ferrous and non-ferrous metals. They efficiently shred materials like steel, aluminum, copper, and more, preparing them for further processing and reuse.Industrial and Manufacturing Sectors: Various industries and manufacturing plants utilize metal shredders to manage their metal waste. These machines aid in

The catalytic converter is an exhaust purification device installed at the vehicle's exhaust outlet. Through oxidation and reduction reactions, it transforms harmful gases such as carbon monoxide, hydrocarbons, and nitrogen oxides emitted from the vehicle exhaust into carbon dioxide, water, and nitrogen. The converter's filter core contains three rare precious metals: platinum, palladium, and rhodium. By dismantling the discarded catalytic converter canister and extracting the filter core, these metals can be further refined.Small-scale recyclers typically disassemble the catalytic converter to obtain the filter core, which is then sold to smelters. Larger recyclers handle the metal recovery and refining process internally. Manual workshops often use dismantling machines to extract the filter core from the canister. However, this method is unsuitable for large enterprises due to significant safety risks and low automation levels, making it inefficient for high-volume tasks.GEP ECOTECH has designed an

Two Shaft Aluminium Beverage Can Shredder

2023-10-21A two-shaft aluminum beverage can shredder is an industrial machine designed specifically for shredding and reducing the size of aluminum beverage cans. These shredders play a crucial role in recycling operations, as they help process aluminum cans into smaller particles for further recycling and material recovery.Video of Twin-Shaft Shredder Shredding Aluminum CansKey Features of a Two-Shaft Aluminium Beverage Can ShredderDual Shafts: As the name suggests, a two-shaft shredder has two parallel shafts equipped with sharp blades or cutting discs. This design enhances the efficiency of shredding and ensures a more thorough reduction of material.Cutting Blades: The cutting blades on each shaft are strategically positioned to cut through aluminum cans effectively. The blades are designed to withstand the abrasive nature of metal shredding.High Torque and Power: Two-shaft shredders typically have high torque and power to handle the tough and rigid nature of aluminum cans. This is important for achieving efficient

The automotive industry produces a substantial quantity of waste materials, particularly in the form of discarded automobile shells. Proper disposal and recycling of these shells are crucial for environmental sustainability and resource conservation. The use of double-shaft shredders has gained significant attention as an effective method for processing automobile shells. This article aims to explore the optimization of automobile shell processing using a double-shaft shredder. Enhanced Shredding Efficiency:Efficiency is the key factor in any waste processing operation. With the double-shaft shredder, the shredding process is optimized to ensure maximum throughput and reduced energy consumption. By utilizing two counter-rotating shafts equipped with sharp blades, the shredder efficiently tears apart the automobile shells into smaller, manageable pieces.Customizable Shredding Configurations:Different types of automobile shells may vary in size, material composition, and structural complexity. The double-shaft

Scrap Metal Processing

2022-03-03Metals are one of the most widely used materials on earth and are a non-renewable resource, consisting mainly of non-ferrous metals (aluminum, copper, zinc, etc) and ferrous metals (iron, manganese, chromium, etc), which are made into a variety of alloyed monomers and alloyed products that are widely used in production and life.Most metals have a huge recycling value and with GEP ECOTECH's metal shredding plants metal products can be efficiently crushed and sorted for transport and subsequent smelting. GEP ECOTECH's shredding solutions are used for sheet metal, drums, stampings, turned parts, metal molds, aluminum products, radiators, copper wire, metal pipes, as well as special alloys, car casings, auto shredder residue, scrap metal briquettes, lead-acid batteries, etc. for shredding and recycling.Please note that heavy sheet metal, metal castings etc. are not handled by GEP ECOTECH equipment.