2 Shaft Shredder Torque Specs

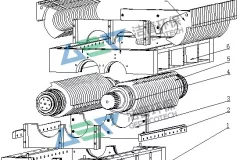

2025-02-15When it comes to industrial shredders, the 2-shaft shredder is one of the most widely used machines for reducing the size of various materials, including plastics, wood, metal, and waste. A critical aspect of ensuring optimal performance and longevity of a 2-shaft shredder is understanding and adhering to its torque specifications.What Are Torque Specifications?Torque specifications for a 2-shaft shredder define the amount of rotational force required for the shredder's shafts to effectively process materials. These specifications are typically provided by the manufacturer and are based on factors such as:The type and density of materials being shredded.The size and design of the shredder's cutting blades.The power of the motor driving the shredder.Torque is usually measured in Newton-meters (Nm) or foot-pounds (ft-lbs) and is a critical parameter for ensuring the shredder operates efficiently without overloading the system.Common Torque Ranges of 2 Shaft ShredderWhile specific torque values can vary from

What is an Industrial Shredder?

2024-04-23In our daily lives, paper shredders are ubiquitous office equipment. However, when discussing industrial shredders, many individuals encounter confusion. Have you ever searched for "industrial shredder" on a search engine, only to find results predominantly focused on office paper shredders? Perhaps you have even encountered platforms that conflate the two, exacerbating your confusion. Rest assured, you are not alone. Here, we will demystify industrial shredders and elucidate their true nature for you. Google search results page confusing industrial shredders and paper shreddersⅠ. ConceptIndustrial shredders are not intended for paper shredding. Rather, they are machines used to cut and tear various materials into small pieces. Due to their widespread use in industrial settings, they are referred to as "industrial shredders."Ⅱ. ClassificationThere exist numerous types of industrial shredders, which can operate independently or collaboratively, serving various industries. They are classified based on

In the realm of waste management, the disposal of bulky items like sofas, mattresses, and furniture presents unique challenges. However, the integration of industrial shredders with balers offers a transformative solution, revolutionizing the processing of these large and cumbersome items. Efficient Shredding of Sofas, Mattresses, and FurnitureIndustrial shredders equipped with robust cutting mechanisms and customizable configurations are capable of efficiently shredding sofas, mattresses, and furniture into smaller, more manageable pieces. These shredders can handle a variety of materials commonly found in these items, including wood, metal, foam, fabric, and plastics. By breaking down these bulky items, shredders significantly reduce their volume, making them easier to handle and process.Optimized Material Compaction with BalersOnce shredded, the materials from sofas, mattresses, and furniture can be efficiently compacted into dense bales using industrial balers. Balers compress the shredded materials,

If you have a requirement for mass or continuous destruction of various storage devices (3.5-inch and 2.5-inch mechanical and solid-state drives, optical discs, flash memory, etc.), choosing an industrial-grade device instead of a consumer-grade device may reduce the risk of downtime . A large Chinese online mall and cloud service provider used AIShred GD5 dual-shaft shredder to destroy decommissioned hard drives and achieved success. "As an e-commerce business established over 20 years ago, we decommission a large number of hard drives every year. Destroying them safely and in a timely manner to ensure data security is our focus. The AIShred dual-shaft shredder processes more than 200 hard drives per hour, and we are satisfied with it without any unexpected downtime for two months", the purchasing director of this company commented that. Using an industrial-grade twin-shaft shredder is a popular method for destroying hard drives and other digital storage devices. Many companies choose to use AIShred's

As the environmental protection field continues to deepen, industrial environmental protection ushers in a new round of peak period, industrial solid waste treatment gradually emerged, setting off a new round of governance boom. At this stage, the popular treatment method of general industrial solid waste is resource recycling. Compaction, crushing, sorting, curing, incineration, biological and other solutions are more commonly used and very reasonable. Minimizing the volume of waste means reducing the volume and quantity of solid waste through appropriate methods of treatment. A brief introduction to the disposal of trimmings and solid wastes generated in light industrial production projects, the main materials handled include: textile trimmings, leather waste, non-woven trimmings and other types of light materials. General industrial waste: waste textile, leather and trimmings, fiberglass, leather, wind power leaves, waste rock wool, rubber, plastic, packaging, industrial pallets, etc. Industrial hazardous

AIShred Destroys Substandard Child Seats

2022-09-05The child safety seat is a kind of seat that is tied to the car seat and has binding equipment for children to ride on and can bind children to ensure their safety in the event of an accident. In many developed countries, it is mandatory to equip children with safety seats. At present, with the improvement of people's safety awareness, more and more parents have also equipped their children with car safety seats. There are two main sources of scrapped child safety seats: one is the scrapped products that have reached the service life, and the other is the unqualified products produced in the factory. How to deal with and recycle these scrapped children safety seats? Let's take the solution AIShred recently provided to a British customer as an example to study it. The main materials of the child safety seat include hardware and software. The hardware includes plastics (PP, ABS, PC, HDPE, etc.) and steel, which are mainly used to construct the skeleton. The soft parts include sponges, fabrics, etc., which are

Fiberglass, Fibre-reinforced plastic(FRP) is one of the most commonly used composite materials in the world today, with a wide range of uses, from wind turbine blades to boats and airplanes, to various containers and support components, fiberglass is everywhere. The main task of disposing of fiberglass is to avoid it being landfilled, because it is particularly difficult to degrade. Now, there are two better ways to recycle fiberglass as I know, the first is co-processing in cement kilns, and the second is to process it into recycled products. Co-processing of Fiberglass Waste in Cement KilnThere are many advantages in the treatment of fiberglass waste in cement kilns. One is that the energy in the waste can be recovered and energy consumption is reduced. The other is that fiber materials, silicon, alumina in the fiberglass can not only reduce the consumption of raw materials, but also improve the quality of cement.Material Recycling of Fiberglass Waste for new ProductsNow a new way of recycling fiberglass

Industrial multi purpose shredders are machines capable of shredding any type of waste: plastic materials, paper and cardboard, wood and organic waste, leather and car rubber, non-ferrous and ferrous metals, etc. Why buy an AIShred industrial shredder? AIShred equipment is universal industrial-type shredders. The machines have good performance and a number of advantages:High torque, capable of shredding many difficult substancesLow power consumption, low noise levelStart at low speed to ensure safetyThe speed can be adjusted to meet the disposal requirements of different materialsVery reliable, can run continuously all the timeLong Blades and Cutters life, repairableAIShred manufactures different kinds of industrial shredders that can be used in various stages of waste disposal or recycling, capable of shredding materials into different sizes. Our main equipment includes, double shaft shredder, single shaft shredder, four shaft shredder, etc.Double-Shaft ShredderThe shredder is equipped with two shafts with

As an industrial shredder manufacturer, providing blades and knives is one of our important jobs. Whether your shredder was purchased from us or not, we have the right blades and knives for you. AIShred's blades and cutters use high-quality raw materials and are machined using high-precision equipment. How to order knives and blades from AIShredIf your shredder is from AIShred, ordering knives and blades is a snap. Please contact your sales manager, he will help you with everything, if you have lost the contact details of your sales manager, please leave us a message and we will arrange everything.If your shredder from another brand, we need you to provide some information, like brand, model, picture, size, etc. Our engineers will fully communicate with you, and it can be produced after confirmation.AIShred Shredders & Spare PartsAs a responsible equipment manufacturer, AIShred cares about the customer's equipment use experience. Improving the service life of equipment and reducing the consumption of wearing

Guide to Industrial Shredder Investment

2022-05-24Shredder, Crusher ,Granulator - Which one is better?Often, the terms shredder, crusher and granulator interchangeably. What's the difference? When you need to shred material into small pieces, it may cost you hundreds of thousands or even millions of dollars to buy a machine, so how to ensure that you are not spending money in vain? To know the answer, we must first clarify two questions: 1) What kind of material do you need to shred and what is the original form of the material? and 2) What size (particle size) do you want the material to be shredded?These two factors will determine the right place for your investment. For example, is your material plastic, paper, rubber, PVC, old tires, household waste, wood pallets, construction waste, iron scrap, medical waste, or something else? What are you going to do with the materials after shredding? How big do you need the material to be shredded, for example 100mm, or 10mm, or smaller? Once you have the answers to these questions, you can choose the right machine

Guide to Industrial Shredder Selection

2022-05-23The environmental community agrees that "solid waste is a misplaced resource", so if you decide to use a shredder to dispose of them in order to make use of the "resource", beware! The wide variety of shredders on the market can be not only dazzling but also confusing. There are even a variety of equipment names: granulators, shredders, crushers, and so on. But for professional solid waste shredding equipment providers, such as AIShred, shredder generally refer to single-shaft, twin-shaft and multi-shaft shredding equipment. On the surface, there is a wide range of shredders readily available, and promotional videos show shredders that can always "eat up" material quickly, with amazing output and results. Unfortunately the reality is that no single shredder can handle different wastes perfectly. Providing the right shredding solution for solid waste requires a deep understanding of the performance and advantages and disadvantages of each type of shredder, and then careful selection. The basic principles of

The AIShred GSS single-shaft shredder is the result of 10 years of experience in mechanical engineering, in the design and manufacture of heavy industrial equipment. It is a single-rotor shredder and is capable of shredding almost all types of industrial and household waste: packaging, chipboard, plastic, wooden boxes, barrels, garbage containers, furniture, mattresses, paper, cardboard, foam plastic, consumer electronics, car and truck tires, etc. This high performance shredder is available in many different versions depending on the materials to be ground, the required capacity and the size of the final fraction. The shredder is available in various versions: mobile or stationary, with electric or diesel drive. Depending on the model, the weight of the shredder varies from 1 to 50 tons. GSS series single-shaft shredders are equipped with a high-performance all-metal rotor. The special rotor geometry increases cutting efficiency by up to 60% compared to conventional shredders. In addition, this

Industrial Scrap Metal Shredder

2022-05-12Metal is one of the most widely used industrial materials, and it can be recycled many times after use without loss of quality. compared with the costs of manufacturing metal elements from ore, the use of recycled materials for these purposes provides a significant economic effect. We offer high-quality shredders for scrap metal. They are the most important equipment for recycling metal products, They are able to shred both light (aluminum, magnesium, copper, nickel) and harder metals (iron, zirconium, titanium, steel, etc.). AIShred's industrial shredders can process the following metal wastes:Scrap Car BodyScrap Metal DrumScrap Metal ProfilesScrap Aluminum AlloyScrap Metal BriquettePunching, Sheet metal, Milling WasteWEEE As leading metal shredder manufacturers, we offer an complete range of scrap metal shredding plants. Whether you need pre-shredders, shear shredders or separation technologies, all our equipment guarantee the highest results in end product cleanliness and purity.

How to Destroy Inert Ammunition?

2022-05-07Every year, the world produces large quantities of expired or substandard military materiel that must be destroyed to ensure safety. Recently we have received several inquiries for military supplies, including firearms, inert ammunition, etc, like blow:I'm looking for a metal shredder machine (not too big)The structure of the targets that the machine has to shred is like pipes (kind of an inert ammunition) and the sizes are: length – 190 mm; diameter – 20 mm; thickness – 4mmThe product must be in pieces less than 5x5 mmI preferred a hydraulic machine – low speed- high torque The total weight of the items that I must shred is 450 ton. I would greatly appreciate if you could send me quotes for several machines that meet the requirements above.Indeed, the twin shaft shear shredders has proven to be the perfect material destruction device. For the destruction of military supplies, its reliability is the main reason why people choose it. At the same time, inert ammunition, it will not be dangerous when squeezed,

The GD Series are high performance twin shaft shredders that are excellent for both dry and wet applications. They are produced in a variety of sizes and can be used to reduce the size of solid waste, reduce particles to improve the efficiency of manufacturing processes, and recycle expired or damaged goods. GD2 shredder is a compact shredder used for shredding hard substances. It's ideal for working in tight spaces while still providing the power you need to grind food scraps, small bones and even silverware. GD2 shredder is the ideal low cost solution for meat and animal processing plants, food processing plants, hotels/casinos/restaurants, ships and more. The GD3 shredder easily handles tough, difficult-to-process items, including metal chips, seafood and food processing waste, and more. The GD6 and its elder brothers are designed for the most demanding applications. Reinforced shafts and seals allow you to grind solid objects to the required size. They have been tested in a variety of industrial

Industrial shredders effectively shred solid wood waste, tree trunks, railway sleepers, various construction waste, tires, solid household waste, old furniture, refrigerator cases, pallets with nails, woodworking waste, wood sheet waste, waste paper, glass waste, plastic waste, volumetric plastic containers, plastic pipes, PET bottles, film, almost any kind of existing solid waste. According to their design, shredders are divided into:Single-shaft shredderTwo-shaft shredderFour-shaft shredderSingle-shaft ShredderA single-shaft shredder is a low-speed shredder with a hydraulic press plate (prepressor) for crushing thick waste and high resistance to shredding: corrugated cardboard, wood waste, wooden boxes and pallets, various types of plastics, bulk polymer containers, plastic pipes, sprues , MSW, car tires.Single-shaft shredder operation principleThe material to be shredded is fed into the shredder's hopper. Loading of material can be carried out manually or mechanically, using an inclined conveyor or loader

Industrial Shredder for Sale Indonesia

2022-04-18Indonesia is a country with a large population, and a large amount of domestic and industrial solid waste is generated every day. The Indonesian government and all sectors of society pay more and more attention to the effective disposal of these solid wastes. Useful materials are recycled, organic materials are turned into compost or biogas, combustible materials are turned into power plant fuels, and hazardous wastes are harmless and destroyed. AIShred manufactures equipment for the pretreatment of these solid wastes - industrial shredders, and has the ability to help contractors design complete solutions. The video above is of an AIShred shredding system that processes industrial waste, separates metals, and makes refuse-derived fuels. With the industrial shredder, it is possible to scientifically process various solid wastes. Whether it is municipal solid waste, organic waste, industrial and commercial waste, mixed waste, it is an essential step to shred it before proceeding to the next step. Considering

Industrial Shredder for Sale Australia

2022-04-13In Australia, if you want to buy a industrial shredder for treatment solid wastes, I'd like to introduce you to our product ranges. Double-Shaft ShredderAs you know, double-shaft shredder is a most common solid waste shredder equipment on the market. It handle almost all kinds of solid wastes and applied in waste reduce, recycling and fuels production. The uniqueness of AIShred double shaft shredder lies in the optimized design for different materials, unlike products such as automobiles, all of our twin shaft shredders can be custom designed and produced to meet unique needs.Single-Shaft ShredderSingle-Shaft Shredder aim the field to fine-shredding, commonly used for material recovery and RDF production. It can shred plastic, textiles, leather, OCC waste, production waste and more. The advantages of AIShred single shaft shredders are stability, durability and ease of maintenance.Pre-ShredderThe pre-shredder is a coarse-shredding machine for pretreatment of solid wastes such as municipal solid waste, scrap

Industrial Shredder for Sale Thailand

2022-04-13In Thailand, many units purchase industrial shredders from China to process industrial and commercial waste, municipal solid waste, or shred tires for fuel production. As the most powerful industrial shredder manufacturer in central China, AIShred is a supplier that many Thai customers must know before making purchasing decisions. First of all, we manufacture industrial shredders that meet all requirements in Thailand. As mentioned above, our shredders have the most extensive use and the most reliable performance, and are widely used in material pretreatment, such as domestic waste mechanical treatment, industrial and commercial waste shredding, production waste shredding and recycling, biomass fuel pretreatment, RDF fuel pretreatment, tire shredding and more. We provide one-stop solution. Secondly, our products are proven in the Thai market. We have cases in Thailand that are highly appreciated by customers, which proves that our product quality and after-sales service meet the general expectations of the

DIN 66399 Heavy Shredder for Sale

2022-04-11New 2-shaft shredder: hard drives, plastic containers, files and other items are shredded safely. A new development is the recently presented 2-shaft shredding machine AIShred GD3. AIShred was recently able to supply this machine for metal post-shredding. With a cutting unit opening of 200 x 500 mm and a drive power of 11kW, it shreds plastic and metal containers, production waste, files and paper waste safely and reliably. Depending on the respective setting, grain sizes between 20 and 80 millimeters or larger are achieved. "Of course, the capacity of this shredder also depends on the materials to be shredded and the desired particle size," explains Harris Yang. AIShred's 2-shaft shredders are equipped with two knife shafts with staggered knives and a perforated screen underneath and are particularly suitable for shredding hard drives and electronic scrap. Here, many customers are particularly concerned with data security during scrapping. The devices from AIShred shred hard drives reliably and powerfully

Slow Speed Industrial Shredder for Sale

2022-04-07AIShred twin shaft low speed shredders are designed to reduce the volume of various materials by grinding the feedstock to a smaller size fraction. It can process materials such as: all types of MSW, C&I Waste, any wood, tires,, plastic wastes, carpets, mattresses, sofa and other materials. By reducing the volume of the source material by several times, this equipment can be used in the following cases:At landfills for shredding bulky waste - extends the life of the landfill by 20–30%;At sorting stations and waste processing plants - for shredding KGM and MSW with the simultaneous function of a "bag opener";At enterprises for the processing of wood waste - for chipping wood;In conjunction with a solid waste press packer - for preliminary shredding of solid waste;At manufacturing enterprises where shredding of various materials such as production waste, drywall, batteries, etc. is required.Shredders can be driven either by electric motor or by hydraulic. They can be both stationary and mobile with various

Industrial Shredder for landfill

2022-04-07According to the statistics, 70% of global waste is currently sent to landfills, often in an unregulated way. Household waste consists mainly of organic waste such as food, paper, cardboard, plastic or wood, while commercial waste typically consists of rubble, bricks, soil and concrete. Waste shredding is an effective way to reduce the need for landfills. Shredding makes it possible to mechanically separate various materials, allowing more homogeneous material to be fed into the sorting plant. This ensures more efficient sorting, better-functioning equipment and a higher share of recycled material. Shredded waste material can be roughly divided into two kinds of material: the kind that can be reused for similar purposes, and the kind that can be reused for other purposes – such as fuel for Waste to Energy plants. So shredding not only limits piles of waste, subsequently lowering transport costs – it also eliminates the environmental damage that would result from leaving waste untouched. And finally, it

We are literally drowning in waste, and it is even expected that global waste production will increase by an astronomical 70% by 2050. Today, low-income countries recycle just 4% of their waste. It’s crucial to recycle as much as possible so that materials from end-of-life products can be given a new life in new products. Material recovery facilities and recycling plants can improve productivity by increasing throughput and accelerating the recycling process. The more effectively different metals, plastics, glass, paper, cardboard, decomposable and other materials are separated from mixed waste, the more sellable products the recycling unit can produce. However, waste contains a wide variety of different bulky materials that are difficult to process due to their size. Efficient industrial shredders are designed for various types of materials for recovery and recycling processes. They reshape and resize mixed waste into a homogeneous grain size that is optimal for screening and separation, enabling a more

Industrial Shredder for Alternative Fuels

2022-04-06Waste is a stable and profitable energy source. Material that has been used and disposed of can be turned into energy-efficient fuel to replace or complement other sources of energy in various applications. Waste fuels, often referred to as “alternative fuels,” are generally produced from municipal solid waste and commercial and industrial waste. Common types of alternative fuels are refuse-derived fuel (RDF) and solid recovered fuel (SRF). There is enormous potential in alternative fuels. They eliminate waste and limit the purchase of black energy sources. Removing impurities and substances with low energy content allows higher-quality waste fuel to be produced. An efficient and properly designed production process increases the calorific value of the waste fuel and ensures that the fuel is optimal for the application. This has a considerable positive impact on production and finances. We manufacture industrial waste shredders and provide maintenance and professional services for companies producing or