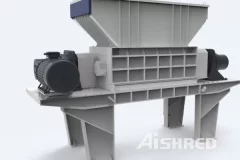

Amorphous strips, commonly used in the production of high-efficiency transformers, magnetic cores, and various electronic components, require specialized shredding equipment to handle their unique material properties. Due to the thin, ribbon-like structure and the toughness of amorphous alloys, selecting the right shredder is crucial for efficient processing. GEP ECOTECH, a leader in the shredding and recycling industry, recommends the dual-shaft shredder as an optimal solution for shredding amorphous strips.Why GEP ECOTECH Recommends Dual-Shaft Shredders for Amorphous StripsGEP ECOTECH's dual-shaft shredder is highly effective for shredding amorphous strips due to its combination of precision, power, and adaptability. Here are some reasons why the dual-shaft design is ideal for this application:High Torque, Low Speed Operation: The dual shafts operate at low speeds with high torque, which allows for the efficient shredding of tough materials like amorphous strips without producing excessive heat or causing

Single Shaft Shredder for Rock Wool

2024-08-21Rock wool, also known as mineral wool, is a commonly used insulation material with excellent thermal and acoustic properties. However, its fibrous and abrasive nature presents challenges when it comes to processing and recycling. A single shaft shredder is an ideal solution for efficiently shredding rock wool, making it easier to handle, transport, and recycle. This article explores the key features of a single shaft shredder for rock wool, including production capacity, output size, feed forms, and maximum feed size, as well as the advantages of using this type of shredder.Key Features of Single Shaft Shredder for Rock WoolProduction Capacity: Typically handles 500 to 300,000 kg per hour, ideal for large-scale operations.Output Size: Adjustable screens allow for consistent output sizes ranging from 10 mm to 50 mm.Feed Forms: Can process rock wool in various forms, including bales, mats, rolls, and loose fibers.Maximum Feed Size: Capable of handling materials up to 2,400 x 1,200 x 2,600 mm.Advantages of

Industrial Cardboard Shredder in Singapore

2024-08-07In Singapore, the efficient management of waste materials plays a crucial role in environmental sustainability and resource utilization. One key aspect of this effort involves the use of industrial cardboard shredders, which are pivotal in recycling and repurposing cardboard waste effectively.Application and BenefitsSimilar to their wood shredder counterparts, industrial cardboard shredders are designed to process large volumes of cardboard waste efficiently. These shredders can handle various types of cardboard materials, including boxes from shipping, packaging, and manufacturing industries. By shredding cardboard waste into smaller pieces, these machines facilitate easier handling, transportation, and subsequent recycling processes.Types of Industrial Cardboard ShreddersSingle-shaft Shredder: Known for high-speed shredding, ideal for producing finer output suitable for applications like paper-making and packaging materials.Double-shaft Shredder: Offers robust processing capabilities for mixed cardboard

In the booming development of the wind power industry, wind turbine blades, as core components, have attracted much attention in their production, use, and disposal. The wind turbine blade shredder, as a key equipment for handling wind turbine blade waste, is gradually occupying an important position in the industry. The wind turbine blade shredder is an efficient mechanical device specifically designed for handling wind turbine blade waste. Its working principle is powered by an electric motor or hydraulic motor, which drives the rotor to rotate. The moving blade, fixed blade, and material tear and cut each other quickly to achieve shredding. Finally, the material is discharged through a sieve and shredded into smaller particles for pre-treatment. The emergence of this equipment not only solves the difficult problem of wind power blade processing, but also effectively promotes the green and circular development of the wind power industry. Through the processing of wind power blade shredder, the waste of

How to Choose Jumbo Bag Shredder Equipment

2024-06-23Recently, we often receive inquiries from customers who want to choose a shredder for jumbo bag. Many customers don't know what equipment to use. Today, let's talk about what equipment to use for crushing jumbo bag.What are Jumbo Bags?Jumbo bags are flexible transport packaging containers known for their advantages such as moisture-proof, dust-proof, radiation-resistant, firm and safe structure, and ease of loading, unloading, and carrying. These characteristics make jumbo bags a widely used industrial packaging product. However, when these bags become waste, they are classified as industrial solid waste, necessitating a reasonable disposal method.Shredders for Waste Jumbo Bags DisposalWaste jumbo bags typically need to be handled by enterprises with the appropriate treatment qualifications. Generally, these bags are first crushed and then incinerated, with most co-processed by cement kilns. For the crushing process, two types of equipment are generally used: double-axis shearing shredders and single-axis

Disposing of cast iron engine blocks presents formidable challenges in the recycling industry due to their dense and robust composition. However, the advent of the Double Shaft Shear Shredder has introduced a game-changing solution, revolutionizing the processing of cast iron engine blocks. Let's explore the unique difficulties associated with shredding these blocks and why the Double Shaft Shear Shredder is the perfect fit for the task. The Challenge of Shredding Cast Iron Engine BlocksCast iron engine blocks are renowned for their durability and resistance to wear and tear, making them notoriously difficult to shred. Their dense structure and complex design require specialized equipment capable of delivering powerful and precise shredding force. Traditional shredders often struggle to effectively break down these blocks, leading to inefficient processing and reduced material recovery. Why the Double Shaft Shear Shredder ExcelsHigh Torque and Cutting Force: The Double Shaft Shear Shredder is equipped with

Saudi Arabia, in its commitment to advancing sustainable waste management practices, has introduced the low-speed, high-torque paper mill waste shredding machines with a remarkable capacity of 20 tons per hour,the machine can efficiently dispose of paper mill ropes, cartons, corrugated paper and other industrial waste. This pioneering project signifies a bold step towards optimizing paper mill waste processing, contributing to environmental conservation, and fostering a circular economy.Equipment IntroductionDual-Shaft Structure: The equipment incorporates a dual-shaft structure, facilitating collaborative efficiency between the two shafts and significantly enhancing processing rates.High-Alloy Blades: Equipped with high-alloy blades, the equipment boasts toughness and wear resistance, ensuring prolonged and efficient operation.Versatile Material Applicability: Handling Diverse Waste: The equipment exhibits outstanding material applicability, capable of efficiently processing diverse waste materials,

In the realm of industrial waste management, the effective processing of cast iron waste is a crucial aspect. Industrial cast iron waste shredders play a vital role in breaking down and preparing these materials for further processing or recycling. Let's delve into various types of industrial cast iron waste shredders, each designed to meet specific needs and requirements in waste management processes.Dual Shaft ShreddersCharacteristics: Dual shaft shredders have two parallel shafts with interlocking blades, enhancing the efficiency of shredding and reducing the size of cast iron waste particles.Applications: Versatile and powerful, dual shaft shredders handle various forms of cast iron waste, producing smaller and more manageable pieces.Quad Shaft Shredders:Characteristics: Quad shaft shredders, with four parallel shafts, provide even greater cutting power and versatility in processing dense and challenging materials like cast iron waste.Applications: Well-suited for heavy-duty industrial applications, quad

Sponges, often used in various applications, can become a substantial waste source. To address the environmental impact and resource utilization, sponge shredders offer an effective solution for recycling and repurposing this material.Introduction to Sponge ShreddersSponge shredders are specialized machines designed to break down used sponges into smaller, manageable pieces. These machines employ cutting-edge technology to efficiently process sponges, converting them into reusable materials.Working Principle of Sponge ShreddersSponge shredders operate on the principle of cutting and grinding. The sponges are fed into the shredder, where sharp blades or cutting mechanisms shred the material into smaller fragments. This process transforms bulk sponges into uniform particles suitable for further processing.Common types of Sponge ShreddersSponge crushers, designed for processing used or discarded sponges, come in various types tailored for specific applications and operational needs. Here are some common types:

How to Choose Ton Bags Shredding Equipment?

2023-11-12Many customers may not know what the ton bag shredding equipment is, so today we will briefly discuss about it. Ton bags are flexible transportation packaging tools that have the advantages of moisture resistance, dust proof, radiation resistance, firmness and safety. They have sufficient strength in structure and are easy to load, unload, and transport. Therefore, they are a kind of highly used industrial packaging product. The waste ton bags belong to industrial solid waste and need to be disposed of in a reasonable way.The treatment of waste ton bags usually requires qualified enterprises to handle them, usually after shredding and incineration, mostly used for collaborative treatment in cement kilns. Two types of equipment are generally used for shredding, double-shaft shearing shredder and single-shaft fine shredder.The double-shaft shearing shredder uses two groups of relatively rotating cutters to form a cutting and tearing effect on materials. The equipment has low rotational speed, high torque, high

GEP ECOTECH's Advanced Industrial Waste Recycling System: Maximizing Efficiency and Sustainability

2023-09-15Aiming at the treatment characteristics of various industrial waste, leftovers, by-products and other solid waste, GEP ECOTECH has developed this industrial waste recycling system, which is centered on an intelligent operation management system and can meet the processing needs of various treatment projects through different equipment combinations. Not only is the overall technology advanced, but customized solutions also make the actual processing efficiency higher.This system is led by a double shaft industrial waste shredder dedicated to industrial waste treatment, which achieves the regeneration and utilization of useful resources in industrial waste through shredding, sorting, reprocessing, and other methods. For example, high calorific value materials are processed into fuels such as RDF or SRF, while low calorific value materials are processed into corresponding resource products based on their characteristics.GEP ECOTECH Industrial Waste Recycling SystemThe production line can shred various types of

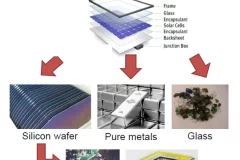

How to Recycle Used Photovoltaic Panels?

2023-02-20Usually the service life of solar photovoltaic panels is about 20-30 years, according to statistics, by 2050 the number of end-of-life photovoltaic panels will be tens of millions of tons, such a huge amount, from the starting point of the circular economy to consider, the recycling of end-of-life photovoltaic panels, in order to achieve the green photovoltaic panels from the source to the end of the environmental protection. So how should the end-of-life photovoltaic panels be recycled? A typical crystalline silicon solar PV panel consists of 65-75% glass, 10-15% aluminium frame, 10% plastic and 3-5% silicon. Recycling is the sorting and reuse of these materials in three main steps: first the PV panel module is dismantled, then it is shredded and finally the valuable metals in the PV panel are extracted by pyrolysis. Shredding as an important part of the recycling process, the photovoltaic panels are first shredded to facilitate the next step of recycling and sorting. Usually choose double-shaft shear

As the environmental protection field continues to deepen, industrial environmental protection ushers in a new round of peak period, industrial solid waste treatment gradually emerged, setting off a new round of governance boom. At this stage, the popular treatment method of general industrial solid waste is resource recycling. Compaction, crushing, sorting, curing, incineration, biological and other solutions are more commonly used and very reasonable. Minimizing the volume of waste means reducing the volume and quantity of solid waste through appropriate methods of treatment. A brief introduction to the disposal of trimmings and solid wastes generated in light industrial production projects, the main materials handled include: textile trimmings, leather waste, non-woven trimmings and other types of light materials. General industrial waste: waste textile, leather and trimmings, fiberglass, leather, wind power leaves, waste rock wool, rubber, plastic, packaging, industrial pallets, etc. Industrial hazardous

Ahead of China's National Day, AIShred has released a new generation of heavy duty single shaft shredders. This new series shredders has been revolutionaryly upgraded, our engineers not only fully adjusted its structural design, but also strengthened the equipment as a whole. The upgraded equipment has stronger shredding capacity and better processing effect in processing of high-strength and complex materials in large production lines. The new product has so many upgrades that it can stand out in numerous applications. Whether it is volume reduction, material recovery or energy recovery, the GSE 3 provides not only reliability, but also greater durability and higher discharge material quality. "The first machine will be applied to the industrial waste disposal project in Zhejiang, China. In addition, we also provided a twin-shaft shredder and an RDF granulator. The customer is quite satisfied with the solution we provided, we are sure it will give our customers a super competitive advantage", said Luhao,

Oil Filter Shredder for Sale

2022-08-18Automotive filters (cars and trucks) and industrial filters (bulldozers and dump trucks) are used to filter various oils. This type of filter consists of different materials: iron shell, bolt, cellulose filter, rubber gasket, mineral oil or synthetic oil. The treatment process mainly depends on the material constituting the filter and whether there is residual oil. The typical recovery method is to discharge the residual oil in the filter, break the filter and separate the metal sheet from the filter paper. Although the used oil filter is a waste, it is illegal to treat it without treatment qualification, but its recycling value is very high. After disassembling it, the waste oil, metal, and filter paper can be recycled, which can be sold and create considerable economic profits. The crushing and disassembling equipment of waste oil filter element and filter is relatively simple. The requirements can be completed by using a double shaft shear crusher + conveyor. Movable containers can be placed under the

Mineral wool is a general term for a class of industrial products, usually including glass wool, rock wool, slag wool, ceramic fibers, etc. Due to their low density, strong heat resistance, sound absorption, and insulation, they are widely used in thermal insulation, sound insulation, filling, etc. Because of the widespread use of mineral wool, inevitably, a large amount of waste is generated, from two primary sources: manufacturing and post-consumer waste. Whether it is rock wool, glass wool, or slag wool and ceramic fibers, they all have recycling value, they can be used to make new mineral wool products, or as an added component to cement or other products, and can also be used to make other building materials such as recycling bricks. Before recycling mineral wool, there is a key step, shred them into small pieces! You will need one or more industrial shredders for this task. AIShred has a wide range of shredding and sorting equipment for material and energy recovery. Our shredding systems have been used

FRP (fiberglass reinforced plastics) products have many advantages, such as high hardness, light weight and corrosion resistance. They are favored by many industrial products and are widely used in chemical industry, engineering, construction, electrical, communication, railway, automobile and other fields. As FRP products gradually reach the life cycle, recycling of waste FRP is becoming a new industry. What equipment is needed to deal with waste FRP? There are generally three directions for the recovery and regeneration of FRP, including chemical pyrolysis, shredding regeneration and energy recovery. First, shredding and regeneration. It is to use the shredder to shred the recycled waste FRP, and sell the FRP fines directly as raw materials, or turn them into FRP, or use them for processing composite materials. Simple and fast operation, typical short, flat and fast business model. Second, energy recovery. This is simpler. You can simply shred the waste FRP, directly package it and sell it to cement plants

The lifespan of solar photovoltaic panels is about 25 years, and more than 95% of the material can be recycled from scrapped and damaged solar PV panels using the latest technology. Aluminum frames can be recycled and sent to refineries, glass can be recycled into glass products, combustibles such as plastics can be recycled for energy, silicon can be reused in the precious metals industry, and heavy metals can be recycled. Due to the rapid development of the photovoltaic industry, a large amount of photovoltaic waste is about to be generated. How to efficiently recycle photovoltaic waste will soon become an important challenge for us. AIShred's low-speed dual-shaft shredder have been successfully applied in solar pv panels recycling plant in a photovoltaic power plant in western China. "This is an experimental photovoltaic waste recycling project. The overall process is to disassemble the aluminum frame, thermally separate the panels, then shred and sort. We chose AIShred among European brands and many

At present, the treatment of industrial waste is not a difficult problem in the industry, but its treatment process will become more complex because of the characteristics of general industrial waste materials. Most of the general industrial wastes belong to composite and low-value wastes. If resources are regenerated directly, the cost of the whole recycling process is high and the process is complex. Therefore, in some industrial or economically underdeveloped places, simple landfill is usually used for disposal, which has a bad effect on the land and environment. In some developed countries and regions, industrial waste is used for collaborative disposal of waste incineration plants, so as to realize energy conversion. At the end of May this year, a customer from Canada finally chose to cooperate with AIShred and purchased a set of industrial waste disposal equipment from our company after multiple inspections and comparisons. Currently, the goods are being prepared.AIShred Disposal Process of Industrial

AIShred Industrial Compost Shredder Machine

2022-07-15Composting factories use organic waste (brown organic waste and green organic waste as well as food waste, slaughterhouse waste, fish, etc.) to produce compost in large quantities. In a composting plant, a shredder is one of the most important equipment, it shreds agricultural and forestry waste and organic waste from kitchens, wet markets, slaughterhouses, etc. into small pieces, which increases their contact area with the air , so that biological fermentation can be carried out efficiently and production efficiency can be improved. AIShred offers industrial shredders and a selection of composters and related equipment, as well as a range of services adapted to your composting needs. AIShred equipment works in industrial and commercial fields and is not suitable for home use. Industrial Compost Shredder Machine In practice, large centralized composting plants typically use slow-speed shredders to process organic waste from the composting process. Its benefits are safe and stable, capable of handling

Industrial multi purpose shredders are machines capable of shredding any type of waste: plastic materials, paper and cardboard, wood and organic waste, leather and car rubber, non-ferrous and ferrous metals, etc. Why buy an AIShred industrial shredder? AIShred equipment is universal industrial-type shredders. The machines have good performance and a number of advantages:High torque, capable of shredding many difficult substancesLow power consumption, low noise levelStart at low speed to ensure safetyThe speed can be adjusted to meet the disposal requirements of different materialsVery reliable, can run continuously all the timeLong Blades and Cutters life, repairableAIShred manufactures different kinds of industrial shredders that can be used in various stages of waste disposal or recycling, capable of shredding materials into different sizes. Our main equipment includes, double shaft shredder, single shaft shredder, four shaft shredder, etc.Double-Shaft ShredderThe shredder is equipped with two shafts with

Waste Shredder for Sale in Maldives

2022-07-08AIShred shredders for sale in Maldives are machine for industrial processing of solid waste, not a home appliance. It is used in hotels, recycling centers, waste management departments, waste transfer stations, Landfills, Cement Plants, Manufacturing Plants and so on. The role of the industrial waste shredder is to reduce the size and volume of waste in batches for material recovery, energy conversion, reprocessing or landfilling. AIShred shredders can handle all solid materials, from food waste, to green waste, from biomass, to municipal waste, from industrial waste to C&D waste. Of course, AIShred provides more than waste shredders, we can also provide users with waste sorting and recycling facilities, and issue design drawings. In the past years, the Maldives has been deeply affected by the covid-19 epidemic. Now the haze of the epidemic is gradually dissipating, and many customers from Maldives are already active. AIShred offers various types and sizes of waste shredders in Maldives, from small stand-

Stranded rope is a common waste refuse in paper mills during the production of recycled paper. This type of waste is mainly composed of plastic, steel wire, pulp and other components, and generally has many impurities and high water content. Stranded rope intertwined, mixed, forming a large volume, difficult to stack and transport. We are with the Korean Group for the industrial waste disposal project in Busan Industrial Park, South Korea; mainly for industrial waste disposal, shredding and sorting as fuel.The customer has also used many other manufacturers' equipment and praised our equipment as the "Mercedes-Benz" of shredders.We use a Double-shaft shear shredder with a 'double motors + double planetary reducers'.The advantages of this machine include high torque, high shearing force, low noise level and low dust generation during the working process. Our cutters are made of NiCrMo, imported from Europe, with high hardness and toughness. The unique anti-winding design of the fixed-cutter is a unique

Industrial Shredder for Sale in Singapore

2022-06-30In Singapore, it is the most convenient to buy heavy equipment from China, because China's heavy equipment is of good quality, has obvious price advantages, and the distance is short and the freight is low. Many developed countries have begun to purchase AIShred's industrial shredders from China. AIShred's shredders have been successfully operated in Singapore and neighboring countries of Singapore. Now I would like to briefly introduce to you.AIShred Small Twin-shaft Shredder for Drug Destruction in SingaporeAs we have covered in this website, item destruction is one of the important uses of AIShred shredders. A drug management center in Singapore uses AIShred's twin-shaft shredder to destroy expired drugs, and then sent to an incineration plant. The advantage of using a double-shaft shredder to destroy medicines is that it is safe and reliable, and it can handle medicines of various packaging types, glass bottles, and iron sheets. AIShred Large-scale Shredding System in Philippine Biomass Power PlantThe