Double shaft shredder is an advanced garbage treatment equipment that plays an important role in the resource utilization and disposal of household waste. The following is a specific explanation of the role of the dual shaft shredder in the resource utilization and disposal of household waste:1. Improve the efficiency of garbage disposalThe dual shaft shredder can efficiently crush large pieces of garbage and convert them into small pieces of material, facilitating subsequent transportation and processing. This high crushing ability significantly improves the overall efficiency of garbage disposal, enabling a large amount of garbage to be properly processed in a shorter period of time.2. Promote resource recycling and utilizationCrushed garbage is easier to classify and sort, thereby improving the efficiency of resource recycling. For example, shredded plastic bottles, paper, and metal cans can be more easily sorted and recycled, achieving the recycling of resources.For organic waste such as kitchen waste,

The Role of Fine Shredders in Secondary Processing of Municipal Solid Waste (MSW)Municipal Solid Waste (MSW) management is a pressing global challenge, and effective waste processing technologies are essential for sustainable waste disposal. In recent years, fine shredders have emerged as valuable assets in the secondary processing of MSW. This article explores the significance of fine shredders in enhancing MSW processing efficiency and promoting resource recovery. Fine Shredders in MSW Processing: Size Reduction for Enhanced Sorting:Fine shredders play a crucial role in reducing the size of MSW materials, making them more manageable for subsequent sorting processes. By breaking down bulky items into smaller particles, these shredders facilitate the extraction of valuable recyclables and organic materials. Increased Surface Area for Biological Treatment:The fine shredding process increases the surface area of organic waste, promoting more effective biological treatment. This is particularly beneficial for

Municipal Solid Waste (MSW) management is a critical aspect of urban sustainability and environmental preservation. In Poland, addressing the challenges posed by MSW requires innovative solutions. A key initiative involves the implementation of a 20-ton/h shredder machine designed for the pre-treatment of MSW.Project OverviewThe primary objective of deploying a 20-ton/h shredder machine is to streamline the preliminary processing of MSW, breaking it down into smaller components for improved subsequent sorting, recycling, and treatment. The chosen machine offers substantial processing capabilities to accommodate the significant volume of waste.Equipment SelectionThe selection criteria for the shredder machine emphasized both the scale and efficiency of the equipment. The chosen machine is equipped to handle diverse materials present in MSW, including plastics, paper, metals, and organic waste. After repeated project research and communication, the project finally selected GEP ECOTECH's GC hydraulic primary

The shredding and recycling of landfill waste poses great challenges to operators, such as large waste capacity, mixed material types, the need for on-site operations, etc. Fortunately, AISHRED has considered all these issues of landfill waste shredding and has launched high-quality, cost-effective, and durable stationary and mobile shredding equipment specifically designed for landfill waste shredding. AISHRED's waste shredding equipment can well meet the arduous daily needs of landfill work, including easily shredding a large amount of waste, bulky waste, tough materials, their solid high torque motors and ultra sharp cutters. Common Landfill Waste Shredding Equipment1. Stationary primary shredderIn the process of landfill waste disposal, the front-end configuration of primary shredder can greatly improve the subsequent screening efficiency and quality, and is an essential pre-treatment process stage. However, stationary primary shredders require high-power power supply and a sturdy and flat installation

With the advancement of urbanization construction, the total amount of MSW/domestic waste generated in daily life is also increasing. The government has also invested a lot of energy in the treatment of domestic waste, and has also implemented policies and guidelines on the treatment of urban domestic waste. Many customers who have first contacted have many doubts about the treatment of domestic waste. Hereby, I will make a brief introduction about the treatment of domestic waste. At present, there are three main ways to treat domestic waste: landfill, compost and incineration. Landfill usually buries domestic waste directly underground to let the waste decompose naturally; The composting method requires the use of equipment to break the organic matter in the domestic garbage, and then degrade the organic matter to make compost; Incineration is the process of crushing and sorting domestic waste, or directly burning it for power generation, or making it into RDF combustion rods, which is basically heat energy

The AIShred MSW Shredder is not only high in shredding efficiency but also easy to maintain. However, the components of municipal solid waste are complex and diverse, which will inevitably cause equipment operation failure. For example, the problem of material winding is a headache for many customers and shredder manufacturers. How to solve these problems? Let follow the step of AIShred to have a brief understanding.Unique Anti-winding Device to Solve the Problem of Material Winding Due to the complexity and diversity of the shredded materials, the domestic waste shredder is likely to encounter problems such as shaft winding, shutdown, sudden power failure and abnormal noise during daily operation. AIShred has successfully developed a unique anti-winding device according to the complexity of materials and the actual operation experience of many projects. During the process of cutting tools inside the domestic waste shredder, we have made special treatment to prevent the wrapping of various plastic bags,

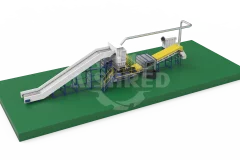

Waste Pre Shredder for MSW

2022-07-11You need a high-availability primary shredder for processing of municipal solid waste, whether for landfilling or making RDF. Shredder is the most common equipment in the field of solid waste management. Its function is to shred solid waste into small pieces for subsequent treatment. When dealing with municipal solid waste, the pre shredder can shred large pieces of waste into small pieces for easy sorting, at the same time, shredded combustible waste have a higher combustion efficiency. AIShred not only provides pre shredders for the treatment of municipal solid waste, but also provides total solutions, click here to view AIShred MSW solutions. How to get your tailored shredder information As you know, even the same model of shredder may use different motors or hydraulic drives, other supporting components may also be different, because the working conditions of each production line are different, so the shredders used in the production line are configured on a case-by-case basis. So how to get shredder

Size Reduction of Municipal Solid Waste

2022-06-16Size reduction is defined as operations or processes which reduce the size of influent materials through division into two or more subunits. Size reduction of municipal solid wastes (often called shredding, grinding, or pulverizing) is a new concept, and much of the technology has been borrowed from the mining and rock-crushing industry. Because solid waste is a heterogeneous mixture(unlike rock), much of the technology is not directly transferable; and size reduction of solid waste has not always been efficient; however,as more solid waste systems have been built, the technoloqy of solid waste size reduction has been sianificantly advanced. More than 2.01 billion tonnes of municipal solid waste are produced annually worldwide. Land areas suitable for land disposal near urban areas where the bulk of the solid waste is generated are becoming scarce and expensive. Open burning and open dumping have been outlawed in many areas because of pollution and health hazards. Incineration is becoming increasingly more

Domestic Waste Pretreatment Production Line

2022-05-21The composition of domestic waste is different in different regions, seasons and periods. It mainly includes kitchen waste, paper waste, waste textile waste, plastic waste, residue waste, waste metal waste and waste glass. At present, in most areas of China, domestic waste is mainly collected in a mixed way without effective classification, so domestic waste will contain a large number of organic components such as kitchen waste, accounting for 50% - 60%. The high content of kitchen waste also leads to the low calorific value of waste in China, which is generally only about 4000-4800kj / kg. This can easily lead to the failure to improve the calorific value of the back-end boiler, and the need to add coal and other combustion aids to improve the calorific value. In view of this situation, AIShred has launched a complete set of domestic waste pretreatment production line, which can fully solve the problem of complex composition of domestic waste, sort out the recyclable materials in the domestic waste for

Municipal Solid Waste Sorting Plant for Sale

2022-05-17Municipal solid waste sorting plants are designed for the treatment of waste from the residential, commercial and industrial sectors. Contamination levels can be high and some components require special handling. The main sorting operations include screening, magnetic separation and manual sorting. The optical sorting not used because the raw material is usually "dirty". In the mixed waste stream, residues make up approximately 85% of the incoming mixed solid waste. A significant proportion of the residues consists of combustible and biodegradable materials. "Dirty" waste sorting plants are also used to obtain product for composting. However, this compost is of poor quality and this limits the potential market for the product.

Municipal Solid Waste Twin Shaft Shredder

2022-05-11The AIShred GD12 shredder is a very economical, low-speed, twin-shaft shredder specially designed for the processing of household, industrial and commercial waste of coarse, medium and fine fractions, as well as for the processing of old wood. GD12 is great for processing of Municipal Solid Waste. Minimal operating costs with maximum performance, combined with the capabilities of intelligent technology, make the waste shredder an indispensable assistant. The Eco Drive delivers up to 50% energy savings compared to conventional electro-hydraulic drives. A feature of shredders is the ability to remotely monitor the operation and control via internet. By using the most advanced synchronous motors, the maximum level of efficiency is achieved, making the Eco Drive one of the most energy efficient drive systems on the market. Maintenance costs are kept to a minimum as belts, hydraulic pumps and shaft ends are not used on this model. If high performance and, accordingly, an increased rotor speed are required, it is

Pre-processing of Solid Waste

2022-04-12The processing of solid waste usually consists of various mechanical processes, which serve to change the physical and fuel properties of the waste input and its composition in such a way that subsequent processes and possibilities of the waste utilization can be improved. The minimum technical equipment for efficient treatment includes the following installations:Storage and loading facilitiesRemoval of impurities and foreign matterPre-shreddingSolid Waste Treatment ProcessStorage and LoadingShallow bunkers or deep bunkers receive the delivered waste. Bulky impurities can be roughly removed in the flat bunker with the help of wheel loaders or special grabs. Irrespective of this, the delivered waste can be checked here without any major problems. Problematic deliveries can be excluded from the treatment. Furthermore, the separate storage of different fractions (e.g. dry commercial waste, bulky waste, wet household waste) is easier to realize in flat bunkers. They are cheaper than underground bunkers, but

Municipal solid waste (MSW) is household, commercial, and / or institutional solid waste. They consist of everyday items such as paper, grass clippings, plastic bags, furniture, clothing, bottles, rubber, metals, food waste, paints and batteries. They are not only of domestic origin, but also commercial (offices, retail and wholesale, restaurants), institutional (libraries, schools, hospitals, prisons) and industrial (packaging and administration). Most of them are classified as not dangerous. As part of their solid waste management plan, almost all countries are promoting source reduction, recycling and composting to reduce landfill disposal. Several countries have also adopted specific measures for the disposal of certain materials: leaves, grass clippings, yard waste, office waste and computer paper, newsprint, cardboard and corrugated cardboard, glass, plastic, aluminum and steel containers are prohibited in disposal plants. Many plants burn municipal solid waste at high temperatures not only to reduce

We are literally drowning in waste, and it is even expected that global waste production will increase by an astronomical 70% by 2050. Today, low-income countries recycle just 4% of their waste. It’s crucial to recycle as much as possible so that materials from end-of-life products can be given a new life in new products. Material recovery facilities and recycling plants can improve productivity by increasing throughput and accelerating the recycling process. The more effectively different metals, plastics, glass, paper, cardboard, decomposable and other materials are separated from mixed waste, the more sellable products the recycling unit can produce. However, waste contains a wide variety of different bulky materials that are difficult to process due to their size. Efficient industrial shredders are designed for various types of materials for recovery and recycling processes. They reshape and resize mixed waste into a homogeneous grain size that is optimal for screening and separation, enabling a more

Industrial Shredder for Alternative Fuels

2022-04-06Waste is a stable and profitable energy source. Material that has been used and disposed of can be turned into energy-efficient fuel to replace or complement other sources of energy in various applications. Waste fuels, often referred to as “alternative fuels,” are generally produced from municipal solid waste and commercial and industrial waste. Common types of alternative fuels are refuse-derived fuel (RDF) and solid recovered fuel (SRF). There is enormous potential in alternative fuels. They eliminate waste and limit the purchase of black energy sources. Removing impurities and substances with low energy content allows higher-quality waste fuel to be produced. An efficient and properly designed production process increases the calorific value of the waste fuel and ensures that the fuel is optimal for the application. This has a considerable positive impact on production and finances. We manufacture industrial waste shredders and provide maintenance and professional services for companies producing or

Mechanical biological treatment plants use municipal solid waste, commercial waste and industrial waste as raw material. Waste is screened and sorted, and all valuable materials are recovered or used in energy production. There are two fundamental issues in mechanical biological treatment (MBT): firstly, how effectively valuable materials can be retained and impurities sorted out; secondly, how much energy is generated from the processed material by composting, anaerobic digestion and biodrying. Improving both the mechanical and biological parts of the process can have a significant impact on the efficiency of the whole plant. A straightforward way to improve productivity is to tailor the waste material to the optimal size for both separation and energy production right at the beginning of the process. Increased capacity is good news for both the environment and profitability of the plant. Proper pre-shredding turns mixed waste into an easy-to-process grain size, regardless of whether it is packed in plastic

Many processes of co-processing municipal solid waste in cement kilns mostly adopt the method of shredding the waste and then incinerating it in the kiln. Since the municipal solid waste is mixed waste, in order not to affect the cement clinker calcination process and product quality, improve the acceptance ability and control ability of the cement kiln system, shredder machine must be set up. So what kind of shredder is used for pre-processing and co-processing MSW in the cement industry? Today, I recommend a GD series MSW shredder for your reference. GD series double-shaft shearing MSW shredders use the principle of mutual shearing and tearing between two relatively rotating knives to shred materials. Adopt "double motor + double planetary reducer", with strong power and high running stability. It is often used in environmental protection fields such as municipal solid waste disposal, resource regeneration, and waste incineration pretreatment. The equipment has the characteristics of low speed, large

Municipal Solid Waste Processing

2022-03-03Municipal Solid Waste(MSW) originates from domestic and general commercial activities and its main components include plastics, waste paper, metals, wood, food scraps, etc. In less developed areas, municipal solid waste is transported directly to landfill, which not only takes up a lot of land resources, but also contaminates the soil and groundwater, and the irritating gases can pollute even the surrounding kilometres.By shredding and screening municipal solid waste, valuable materials such as metals can be recovered and combustible materials can be made into waste-derived fuels for power or heat generation, while organic materials can be fermented to make compost or biogas.GEP ECOTECH shredding and screening technology effectively treats a wide range of municipal solid waste, both sorted and unsorted, using simple equipment for well sorted waste and a wide range of different equipment for unsorted waste.In addition, we can provide landfill stock disposal facilities to reduce pollution and extend the life