Practical Guide to Alternative Fuels for Fossil Fuels, RDF/SRF/TDF & Biomass Fuel Produnction System

2025-03-26We specialize in the design and manufacturing of efficient, environmentally friendly Solid Recovered Fuel (SRF) and Refuse-Derived Fuel (RDF) processing equipment. Our state-of-the-art production lines transform various waste materials into high-quality alternative fuels, effectively addressing waste management challenges while delivering sustainable energy solutions for businesses.

The traditional RDF (Refuse-Derived Fuel) production process mainly relies on heavy-duty single shaft shredders for shredding treatment, sometimes using double shaft shearing or primary shredding as pretreatment equipment to improve material processing efficiency. However, this process presents many challenges: the price of single shaft shredders from some world well-known manufacturers may reach as high as USD850,000, putting significant financial pressure on small and medium-sized enterprises in the initial investment stage; The power consumption for ton processing can reach 50 kW·h, which not only increases operating costs, but may also require additional procurement of high-capacity transformers to meet demand; In addition, wearable parts such as cutters wear out quickly and often require repair or replacement within a few days, thereby increasing maintenance costs. These factors limit the cost control and production efficiency of traditional process, affecting the long-term sustainable development of

In 2023 GEP Ecotech supplied a GS series single-shaft fine shredder to a customer in Poland for shredding RDF Waste. The shredder delivered exceptional stability, with the customer highly satisfied with the installation speed, final product size, output, and after-sales support. This success reflects GEP's commitment to providing efficient and reliable shredding solutions.Introduction to GS Series Single Shaft Fine ShredderThe GEP GS series single-shaft fine shredder is designed for optimal performance in waste reduction and recycling applications, particularly for Refuse-Derived Fuel (RDF) production. Its key components include:Main ShaftRotary Cutters and Fixed CuttersShredding ChamberFeeding and Pushing SystemsPower SystemThis shredder is known for its small particle output, replaceable screens, and high shredding efficiency. It also has a wide range of material applicability, making it suitable for various waste types.Key Features and Advantages for RDF ProcessingPrecise Output Control: The GSS series

In the pulp and paper production process, it will produce a variety of solid waste (i.e., slag), for example, an annual production capacity of 1 million tons of paper mills, the amount of slag accounted for about 10% of the amount of slag, i.e., 100,000 tons / year, which is a huge number, and highly concentrated, such as improper disposal, but also cause significant pollution and endanger the ecological environment. The composition of paper waste is very complex, mainly contains: rope, cotton yarn, cotton cloth, paper residue, wood chips, rubber, plastic, electronic parts, wire, nails, aluminum cans, PE plastic bottles, waxed paper and glass, stone and sand. Paper waste residue can be used to make solid alternative fuels, a utilization that not only reduces waste, but also replaces traditional fossil energy sources and reduces carbon emissions.The plastics in paper waste residue cannot be degraded, and direct stacking seriously affects the ecological environment. At present, there are paper waste separation

RDF Shredder Machine for Sale, Get Quotation for Your Waste-to-Fuel Solution with one Click

2023-07-22In today's world, the escalating volume of waste has overwhelmed traditional landfill disposal methods, resulting in wasted space and valuable resources. To combat this issue, the conversion of waste into solid fuel has become a popular solution. Two essential products of this process are RDF (Refuse-Derived Fuel) and SRF (Solid Recovered Fuel). These fuels are obtained through advanced shredding and processing techniques that transform waste into valuable energy sources with high calorific value. The waste shredder plays a vital role in this waste-to-fuel transformation process, efficiently breaking down waste materials and creating homogeneous fuel products. RDF and SRF offer sustainable alternatives to conventional fossil fuels, contributing to a more eco-friendly and resource-efficient future.RDF PlantThe RDF (Refuse-Derived Fuel) plant is a specialized facility designed to efficiently convert solid waste into RDF, a valuable solid fuel with high calorific value. The RDF plant's workflow involves several

During the production of cement, clinker needs to be calcined at a high temperature of 1300-1450°C, which will consume a large amount of fossil energy, and the carbon dioxide produced by the combustion of fossil fuels accounts for about 30%-35% of the total carbon emissions of cement companies. The application of alternative fuels to reduce the use of coal has received attention in the cement industry and can significantly reduce the carbon emissions from fuel combustion. As a promising renewable energy source, alternative fuels (SRF/RDF) have become the fourth largest energy source after coal, oil and natural gas for various industrial kilns such as cement kilns and fluidized beds. Alternative fuels as a high-quality environmentally friendly renewable resources, itself from solid waste waste treatment, combustion efficiency and fossil fuels similar, but low carbon emissions, to meet the policy requirements of carbon emission reduction, cost savings for enterprises, has an important significance for

Fuel Production From Household Waste

2023-05-22In recent years, the popular term "RDF" in the field of solid waste refers to waste derived fuels, and most environmentalists have also turned their attention to the field of household waste. The composition of household waste we usually refer to is a mixture of wet waste and dry waste, while in the preparation of fuel for household waste, it is best to make a distinction based on current incineration needs. Frontend differentiation can reduce the investment cost of pre-treatment production lines while also improving the calorific value of materials. In the field of incineration, calorific value is a sensitive term. In fact, this process flow is not complicated. Our designed process principles have three positioning points: "impurity removal, reusable selection, and combustible compression". These three process points constitute the equipment solutions applicable in the current field of solid waste disposal. The impurity removal we refer to can be understood as the purification of household waste. There will

"Eat" into waste, "vomit" out of fuel, and become a "artifact" that turns waste into treasure in Zhengzhou, Henan. The Industrial Solid Waste Disposal System produced by GEP ECOTECH can "eat" 20 tons of C&I waste in one hour and produce preparations Popular alternative fuel RDF/SRF. So what craftsmanship does GEP ECOTECH make "people suspected" and make the waste into the "fragrant" of the fuel industry?Waste is an abandoned item that loses its value and cannot be used. It is the ultimate part of the material cycle. The widely used waste treatment methods today are sanitary landfills, high temperature compost and incineration. However, most of the industrial waste incineration contains considerable heat values, and directly landfills or incineration undoubtedly causes waste of resources. Now, this industrial solid waste disposal system located in Zhengzhou, Henan can effectively use general industrial solid waste such as leather edge, cloth edge corner, waste paper residue, waste fabric, waste plastic, etc

RDF Pelleting Machine for Sale

2023-02-28RDF refers to refuse-derived fuel, which is fuel obtained from waste. According to the standards of the American Inspection and Materials Association, RDF can be divided into seven categories: RDF1 to RDF7. Generally, RDF refers to shaped RDF pellets, which are derived from municipal solid waste and obtained after shredding, sorting and pelleting. The RDF technology brings life to the energyization of waste and becomes a new growth point in the field of waste utilization. It is widely used in coal-fired power plants, thermal power plants, waste incineration power plants, thermal power plants, cement plants and other enterprises, effectively accelerating the transformation and upgrading of power, gradually realizing green and low-carbon power production, and contributing to the global energy transformation. In order to produce high-quality RDF, besides shredding and screening equipment, RDF pelleting machine is also very important. High-quality RDF equipment can reduce your energy consumption and reduce the

Facts: Municipal solid waste contains a large amount of high calorific value components, which will not be effectively utilized if the waste is directly incinerated or filled up. Through the existing thermal power plants, thermal power plants, cement plants for coupling power generation, co-disposal, combined with RDF fuel briquetting production technology, without landfill, without large investment in the construction of waste incineration power plant, urban household waste, industrial solid waste can be "harmless, reduction, resource, energy" comprehensive use of treatment applications. As MSW is incinerated directly as a solid fuel without treatment, the following main problems often exist.the organic matter in the waste is highly perishable, making transportation and storage more difficult.the waste is characterized by large fluctuations in composition and calorific value, high moisture and ash content, which can easily cause unstable combustionwaste often contains plastic, salt and other chlorine-

RDF Shredders for Waste-to-Fuel

2023-02-14Derived fuel has the characteristics of high calorific value, stable combustion, easy transportation, easy storage and low secondary pollution, which is widely used in drying engineering, cement manufacturing, heating engineering and power generation engineering. RDF raw materials mainly come from domestic waste, industrial waste, organic waste, etc. It contains waste paper, hard plastic, metal, glass, wood, rubber and other substances. The coarse shredder and fine shredder meet the crushing requirements of RDF, greatly simplifying the RDF treatment process and realizing high economic and ecological value. Equipment Configuration The crushing of this high mixture of materials places high demands on the crushing technology. The stable operation of the shredder requires high performance alloys and high reliability of the whole machine. This type of crushing requires a machine capable of handling hard materials such as metals and plastics. To obtain a high quality RDF, the following steps need to be performed:

There is a lot of domestic waste produced in cities every day, which is increasing. Therefore, it is an urgent task to seek a way of recycling treatment of municipal solid waste. Converting municipal solid waste into waste derived fuel, namely RDF (Refuse Derived Fuel), is a mature waste treatment method in developed countries. RDF fuel has been widely used in the United States, Europe, Japan and South Korea to generate electricity or heat. How Does Municipal Solid Waste Become RDF?The production process of RDF is to first use sorting equipment to classify urban domestic waste, separate the recyclable parts according to different material properties, and then separate the waste plastics, waste paper scraps, wood chips, PVC and other combustible wastes from the waste through screening steps such as magnetic separation, air separation, non-ferrous metal screening and other steps, and then crush, dry and grind them into granular fuel. RDF is extruded and solidified into granules at high temperature. The RDF

Waste Wood RDF Forming Process

2022-08-23RDF technology is the world's umbrella term for solid waste treatment technologies for small and medium-sized cities with a capacity of 400 to 1,200 tonnes of domestic waste per day. RDF can solve the perplexity of cities with long-standing waste enclosures and is a new technology to replace outdated landfills that pollute air, groundwater and crops. Wood can be found everywhere in life and is obtained in various ways, such as logs, paper mill trimmings, waste and bulky waste(sofas, tables, chairs and benches, etc.). Wood itself has a high recycling value, and with the prevalence of RDF technology today, the recycling and use of wood is becoming increasingly popular. The wood itself has a high calorific value and for the wood RDF forming process, a low speed high torque double-shaft shredder (used as pre-shredding) + chipper + wood shredder + pelletizer (forming machine) is generally used. With some auxiliary equipment such as: chain conveyor, iron remover, negative pressure dust collector, etc. Please feel

How Much does a RDF Plant Cost?

2022-05-16Alternative fuel RDF(refuse derived fuel) or solid secondary fuel is a fuel obtained from waste. RDF contains high-calorie waste components such as plastic, paper, cardboard, textiles, rubber, leather, wood, etc.RDF can be used as main or supplementary fuel in furnaces of cement plants, thermal power plants, metallurgical furnaces. The calculations performed showed the expediency of replacing gas or coal with RDF in the production of cement.The production of cement requires significant energy costs due to the need to maintain the temperature in cement kilns above 2000°C. For each ton of cement produced, typically 60-130 kg of fuel oil, or its equivalent (natural gas, coal), and about 105 kWh of electricity are required. On average, energy, fuel and electricity costs account for up to 40 percent of cement manufacturing costs. Therefore, it is advisable to use alternative fuels obtained from waste in production processes in order to reduce the use of traditional fuels and raw materials by replacing them with

Plant for Production RDF and SRF

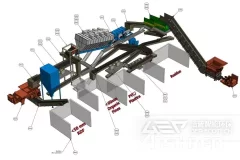

2022-05-09Refuse Derived Fuel(RDF) and Solid recovered fuel(SRF) is the final product of a complex production process which is modernly defined as the "chain of differentiation, recovery and recycling of municipal solid waste". RDF/SRF is an excellent fuel with a great energy power and a very limited cost, in addition, turning waste into RDF/SRF also reduces landfill space and many other costs. RDF/SRF Production Process The RDF/SRF preparation process consists of several processes: a primary shredding, screening, separation, removal of ferrous and non-ferrous metals and a final shredding. Different material compositions and specific requirements may increase or decrease certain processes. At the waste treatment site, Minhang Sanitation Company processes overproduction, bulky waste fractions, large packaging and unsorted municipal solid waste by transforming them into waste-derived fuels (RDF) of various qualities. The company specialized in disposal supplies waste incineration plants, but mainly cement plants, for