Iron Scrap Shredder Machine in Malaysia

2025-02-05Recently, our GEP iron scrap shredder production line was successfully shipped to Malaysia. To ensure the smooth operation of the project, our engineer traveled to Malaysia to oversee the installation and provide technical guidance on-site.Customized Production LineTo meet the specific requirements of the Malaysian customer, we customized the production line based on the desired output, processing capacity, and available workshop space. Adjustments were made to the chamber size, cutter arrangement, and the number of cutter teeth to optimize performance. This tailored approach has gained recognition and approval from our Malaysian client.Introduction to the Malaysia ProjectFor this project, the production line is designed to process iron scrap with high efficiency.Input Material: Various types of iron scrap, including metal sheets, bars, and castings.Processing Capacity: Approximately 6 tons per hour.Output Size: Shredded pieces of 3-5 cm, suitable for recycling and smelting.The production line includes a

Heavy Duty Metal Debaler for Sale

2024-12-31Today, we are introducing the metal debaler, also called metal bales opener/breaker, a machine widely used in the metal recycling industry. This compact, robust, and powerful equipment delivers excellent performance in improving efficiency while significantly reducing labor and time costs.One of the key challenges in metal recycling is maximizing your input-output ratio. Typically, you don't want a production line that is either too powerful or too small. In many of GEP Ecotech's case studies, our customers have successfully addressed these challenges with this equipment.Similar to traditional agricultural baling processes (e.g., straw or stalks), baling materials helps save a considerable amount on transportation costs. However, it also introduces the challenge of unbaling the materials before moving on to the next stage of processing. In metal recycling, if you are unable to efficiently unbale the materials, you may face several issues:Over-investing in larger shredders: This would significantly increase bo

Proposal for Copper and Aluminum Scrap Shredder for Large Parts (Engine Parts, Wheel Rims, etc.)

2024-11-30Today a famous South African metal recycling company asked us for a 6 ton/hour copper and aluminum shredder, to crush big parts, like engine part, wheel rim and etc., the volume of the material is reduced by at least half. Based on the requirements, we have tailored the following proposal for our customer.Recommended Shredding Solution: GD8 Double-Shaft ShredderBased on your specific needs, we recommend our GD8 Double-Shaft Intelligent Shredder. This shredder is designed to process large and tough materials like engine parts and wheel rims, making it ideal for your copper and aluminum scrap recycling requirements.Key Features of the GD8 Double-Shaft Shredder:Motor Power: 2 x 55kW or 2 x 75kW (customized to meet your throughput needs).Cutting System: High-strength NiCrMo alloyed steel cutters, perfect for shredding large, tough non-ferrous materials.Hydraulic Feeding System: Ensures smooth operation by efficiently pushing large parts into the shredder.Control System: Integrated with the GEP intelligent

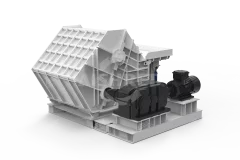

Scrap Aluminum Hammer Shredding Production Line Production line introductionScrap Aluminum Shredder is a kind of shredding equipment used to process scrap aluminum, which is mainly used for the shredding and sorting operation of machined aluminum, raw aluminum, aluminum alloy and broken aluminum. With advanced technology, large processing range and high production efficiency, the production line can fully separate iron, aluminum and plastic, and the purity can reach more than 99%, and the production process is noiseless and non-polluting, which is the mainstream equipment for scrap aluminum recycling at present. Process FlowScrap aluminum shredding and sorting equipment consists of scrap aluminum shredder, magnetic separator, trommel screen, eddy current sorter and dust collector. The material is sent into the aluminum shredder for fine shredding through the conveyor, and the shredded material is separated from iron by the magnetic separator, and then it enters into the trommel screen to separate the

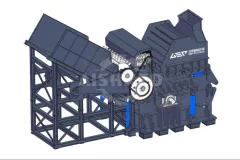

Scrap Steel Hammer Shredding Production Line

2024-11-19Scrap steel shredding production line is used to process scrapped car body, tinplate, old home appliances, bicycle and electric car frame, can briquettes and other light and thin wastes to make them into pure raw materials for steel making. Through continuous shredding and extrusion, it can remove impurities, increase the specific gravity of heap, reduce the cost of transportation and smelting, and meet the requirement of “fine material into the furnace” of the steel mill.Scrap steel shredding production line has advanced technology, large processing range, high production efficiency, can sort out the non-ferrous metals, remove non-metallic inclusions, processing of high-quality scrap steel with high purity, and less environmental pollution in the process. Scrap steel processed through the scrap shredding production line is clean and high-quality scrap steel, its natural bulk density of 1.2 ~ 1.7t/m3, is the ideal steelmaking furnace material.Process flowScrap steel shredding production line consists of

55kW Metal Shredders in Hungary

2024-10-29Project BackgroundIn recent years, Hungary has made significant strides in enhancing its recycling capabilities, driven by the growing demand for sustainable waste management solutions across Europe. To support this effort, a metal recycling company in Hungary sought a reliable and efficient shredder capable of processing large volumes of scrap metal, including metal drums, aluminum profiles, and other industrial waste materials. This company partnered with GEP Ecotech, a leading provider of industrial shredding and recycling equipment, to install a 55kW metal shredder as part of its state-of-the-art recycling facility. Equipment Overview: 55kW Metal ShredderThe 55kW metal shredder provided by GEP Ecotech is a dual-shaft shredder specifically designed to handle tough metal materials. This equipment combines high-capacity processing with energy efficiency, making it ideal for both medium and large recycling facilities. Key specifications of the shredder include:Model : GD8 Double-shaft intelligent shredderCapi

Today, in our factory, I was struck by the sight of our shredder efficiently processing various types of scrap iron, all with thicknesses up to 6 mm. The scene was a testament to the shredder’s robust design and advanced technology, showcasing its ability to handle tough, metal waste with precision and ease. Overview of the GDI Double Shaft ShredderThe GDI double shaft shredder is engineered to tackle tough, thick materials like scrap iron with precision and efficiency. Featuring two parallel, counter-rotating shafts equipped with heavy-duty blades, this shredder is capable of reducing large and robust metal pieces into smaller, manageable fragments. Its design is tailored for industrial use, making it ideal for environments where high-volume metal processing is required.Key Features and Functions of the GDI Double Shaft ShredderIn the realm of metal recycling and waste management, the efficient handling and processing of scrap iron are crucial for resource recovery and environmental sustainability. The GDI

The non-ferrous metal recycling industry in Ireland is a dynamic sector focusing on the recovery of metals such as aluminum, brass, copper, and precious metals from various sources, including electronic scrap. With diverse needs ranging from large-scale corporate recyclers to smaller operations recovering valuable metals from electronic components, selecting the right shredding equipment is crucial. GEP ECOTECH offers a comprehensive range of non-ferrous scrap metal shredders designed to meet these varied requirements effectively.GEP ECOTECH Shredding SolutionsGEP ECOTECH is renowned for its extensive lineup of non-ferrous metal shredders, providing versatile and efficient solutions for metal recyclers. Their equipment is designed to handle a broad spectrum of metal recycling applications with ease and precision.GEP Dual-Shaft ShredderVersatility: Ideal for shredding bales or drums, these models are highly tolerant of tramp metals, making them suitable for a variety of non-ferrous scrap materials.Power

Recently, we received exciting news from our South Korean customer: the GD9Q dual-shaft shredder we supplied has been officially put into operation for scrap metal shredding.The customer, a prominent metal recycling company, handles a variety of scrap metals, including copper-clad laminate, circuit boards, copper-coated steel waste, and copper shavings. They use our GD9Q shear shredder to reduce these materials into pieces of about 10 cm for further processing.The GD9Q is an enhanced version of the GD9, specifically designed to deliver greater shearing force and durability for demanding applications. The installation process was supported by GEP ECOTECH’s technical team, ensuring a smooth and efficient setup.This project is one of the many successful metal recycling projects recently executed by GEP ECOTECH. In the current global economic downturn, many environmental projects dependent on government investments or subsidies have been delayed or canceled. However, metal recycling remains a lucrative

Waste Iron Barrels Shredding Project

2024-07-11The disposal of waste iron barrels has long plagued the industry and waste management departments, but with the increased awareness of resource recycling and technological advances, waste iron barrels shredding projects are gradually becoming an effective way to solve this problem. Economic Analysis and Capital InvestmentCapital investment and revenue expectations are important considerations for project feasibility. Through a detailed assessment of the costs of equipment procurement, personnel training, daily operations, etc., combined with an analysis of the market value of the recovered metals, the economic benefits of the project can be reasonably predicted. AI Shred’ Environmental protection carries out thorough financial planning before the project to ensure the reasonableness of the input-output ratio of the project. Environmental Impact AssessmentEnvironmental impact assessment is an indispensable part of the waste iron barrels shredding project. During the implementation of the project, the

Innovative highlights of scrap metal shredders Scrap Metal Shredder, a machinery and equipment designed for converting waste metals into small pieces of materials that are easy to manage and reuse. It plays an irreplaceable role in many metal recycling processes, such as scrap iron and steel, scrap non-ferrous metals and dismantling of end-of-life vehicles, which greatly promotes the efficient recycling of metal resources. The core competitiveness of the scrap metal shredder lies in its unique shredding mechanism. Through the precision cooperation between the high-speed rotating movable knife and the stationary fixed knife, it generates extremely strong shearing force, and gradually breaks down the scrap metal entering the shredding room into smaller particles. After the initial processing of these metal fragments, through precise screening and classification, they can be directly put into the smelting process, realizing the second life of resources. Innovative highlights of the scrap metal shredder

With growing environmental concerns and the pressing need for sustainable practices, the metal recycling industry in Australia is witnessing significant advancements. Efficient and robust metal recycling equipment is pivotal in meeting the increasing demand for metal recovery and processing. This article explores the various types of metal recycling equipment available for sale in Australia, their features, applications, and the benefits they offer to recycling operations.Types of Metal Recycling Equipment1. ShreddersFeatures and ApplicationsShredders are fundamental in the initial stage of metal recycling, breaking down large metal pieces into smaller, manageable fragments.Single-Shaft Shredders: Suitable for processing lighter materials and providing precise control over output size.Dual-Shaft Shredders: Known for their robust design, these shredders can handle heavier, bulkier metal waste, including automotive parts and industrial scrap.Four-Shaft Shredders: Offer superior cutting efficiency and are ideal

Disposing of cast iron engine blocks presents formidable challenges in the recycling industry due to their dense and robust composition. However, the advent of the Double Shaft Shear Shredder has introduced a game-changing solution, revolutionizing the processing of cast iron engine blocks. Let's explore the unique difficulties associated with shredding these blocks and why the Double Shaft Shear Shredder is the perfect fit for the task. The Challenge of Shredding Cast Iron Engine BlocksCast iron engine blocks are renowned for their durability and resistance to wear and tear, making them notoriously difficult to shred. Their dense structure and complex design require specialized equipment capable of delivering powerful and precise shredding force. Traditional shredders often struggle to effectively break down these blocks, leading to inefficient processing and reduced material recovery. Why the Double Shaft Shear Shredder ExcelsHigh Torque and Cutting Force: The Double Shaft Shear Shredder is equipped with

In Xizang, China, efficient metal recycling is vital for environmental sustainability. At the forefront of this effort is the GEP's GD model double shaft shredder, a robust machine designed for processing scrap iron metal. Let's explore its operational performance in Xizang's metal recycling industry.Consistent ThroughputThe GEP's GD model double shaft shredder boasts a remarkable throughput capacity of 10 to 15 tons per hour, ensuring continuous and efficient processing of scrap iron metal.Its high-performance motors and precision-engineered cutting blades enable smooth and uninterrupted operation, maximizing productivity.Reliable OperationOperating in Xizang's challenging environmental conditions, the GEP's GD model double shaft shredder demonstrates exceptional reliability and durability.Its robust construction and advanced safety features ensure safe and reliable operation, even in harsh industrial environments.Customizable Shredding ConfigurationsThe GEP's GD model double shaft shredder offers

A scrap metal crusher, also known as a scrap metal granulator or metal shredder, is a device designed to reduce metal waste into small pieces for easier transport and recycling. Learn more about the criteria for purchasing a scrap metal crusher and discover the features and advantages of GEP ECOTECH scrap metal crushers

Shredder Machine for Light Metal

2024-03-21In the realm of metal recycling, the efficient processing of light metals such as aluminum, magnesium, and alloys is crucial for sustainable resource utilization. Light metal shredders play a pivotal role in this process, enabling the effective fragmentation and separation of metallic materials for recycling purposes. Key Features of Light Metal ShreddersHigh-Speed Shredding: Light metal shredders are equipped with high-speed rotor assemblies and sharp cutting blades to ensure rapid and efficient shredding of metal components. Variable speed controls and adjustable shredding parameters allow operators to customize shredding processes according to specific material characteristics and recycling requirements.Material Handling Systems: Light metal shredders feature robust material handling systems, including conveyor belts, feed hoppers, and discharge chutes, to facilitate continuous and uniform material flow. Automated feeding and discharge mechanisms optimize shredder throughput and minimize downtime for

Scrap iron wire is an infinitely recyclable renewable resource and an excellent iron-making material, so the recycling of scrap iron wire is of great significance. So how do we recycle scrap iron wire? When recycling scrap iron wire, we need to carry out some formal processing to better improve the utilization rate of scrap iron wire, of which shredding is a very important step.However, the shredding of various mixed wires brings particularly huge challenges to industrial shredders. Scrap wire is highly abrasive, heavy, and often bulky. The emergence of GDI shear shredder has successfully solved this problem. It has a good shaft structure design, low noise, durability, easy replacement of blades, and can easily break bundles of wire or loose iron. We call this The machine is a scrap wire shredder.Features of GDI scrap wire shredder:The scrap wire shredder runs slowly, has low noise and less dust.The blade material is made of special alloy steel and has a long service life.Powerful shredding capabilities and

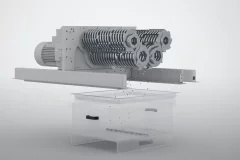

Steel Swarf/Chips Shredder

2024-02-23Steel swarf/chips are usually used in electric arc furnace steelmaking, in order to recycle, but this recycling has its drawbacks, one is the recycling rate is low, the general recovery rate of 84% or so, in addition, the amount of fumes generated by large, large energy consumption; there are also used in the medium-frequency furnace, such as the melting of the steel swarf/chips, but the amount of suction of steel is large, the content of impurities is large, the billet cast out of the steel or made of materials of unstable quality, the use of scrap steel swarf/chips has become a thorny issue. Steel swarf/chips shredder adopts planetary gear reducer drive, the cutters are made of NiCrMo alloy steel, has strong wear resistance and high strength etc. characteristics, differential speed operation between the shafts, has the function of tearing, squeezing, biting and so on. The electrical part is controlled by PLC, with automatic detection of overload protection and other functions. Advantages of steel swarf/

With the continuous development of industrialization, the disposal of scrap metal has gradually attracted people's attention. Scrap metal shredder as an efficient, environmentally friendly processing equipment, has gradually become the first choice in the field of scrap metal processing.First of all, the scrap metal shredder has a very high processing efficiency. Through the powerful shredding force, the scrap metal can be quickly shredded into small particles, greatly reducing the processing time. At the same time, the shredded metal particles are easier to store and transport, providing convenience for subsequent processing.Secondly, the scrap metal shredder has significant environmental advantages. The traditional way of handling scrap metal often produces a large amount of pollution, posing a threat to the environment and human health. The scrap metal shredder, on the other hand, adopts advanced low-noise, low-emission design, which effectively reduces the environmental pollution in the treatment process

Aluminium Profile Shredder Price

2024-01-10Aluminium profile shredders play a pivotal role in recycling operations, breaking down robust aluminium profiles into smaller fragments for repurposing. Their prices vary due to multiple factors that determine their cost.Common Models and Approximate Prices1. Model A - Medium Capacity ShredderPrice Range: $30,000 - $80,000Suitable for mid-sized recycling facilities with moderate throughput requirements.2. Model B - High-Capacity ShredderPrice Range: $80,000 - $150,000Designed for larger-scale operations, capable of processing high volumes of aluminium profiles.3. Model C - Specialized Shredder with AutomationPrice Range: $150,000 - $300,000Equipped with advanced automation and safety features for specialized recycling needs.Factors Influencing Aluminium Profile Shredder PricesMachine Specifications: Shredder capacity, power, and design greatly impact pricing. High-capacity machines with advanced features usually cost more.Technology and Features: Shredders with advanced automation, safety features, and

4 Shaft Steel Drum Shredder

2024-01-08Steel drums, commonly used in industrial settings for storage and transportation, play a vital role in various industries. However, after their life cycle, these drums often need to be recycled or repurposed, which calls for efficient shredding processes. The utilization of a four-shaft steel drum shredder becomes crucial in this regard.Why is Shredding Steel Drums Essential in Recycling?Steel drums, due to their durable and robust nature, can be challenging to manage during recycling. Shredding these drums into smaller components is necessary for several reasons:Volume Reduction: Shredding reduces the volume of steel drums, making them more manageable for transportation and further processing in recycling facilities.Material Handling: Smaller shredded components ease the handling of steel drums, ensuring a more efficient recycling process.Resource Recovery: Breaking down steel drums into smaller pieces allows for the recovery of valuable steel materials, facilitating their reuse in manufacturing.Advantages

Scrap Metal Shredder for Sale Australia

2023-12-14Australia has a strong focus on metal recycling, a growing industry where these metal resources are recycled for remanufacturing, construction and other industrial uses. Metal shredders are an essential piece of equipment for metal recycling, so what are the metal shredders on sale in Australia? Let's take a look at a typical metal recycling project in Australia.Introduction to GEP's Australia Metal Recycling ProjectThis project is a solid waste treatment and recycling project invested by Australia's leading aluminum material production and processing company. This production line integrates three common metal shredding equipment (coarse shredder, medium shredder, double-shaft shredder, fine single-shaft shredder) and high-efficiency sorting equipment (magnetic separator, eddy current Sorting machine and trommel screen). The entire production line has practical technology, strong functionality, and high utilization rate of scrap metal resources.Metal Recycling Project in Australia Australia Metal Shredders

Scrap steel is a valuable resource that can be utilized to reduce dependence on mining and to contribute towards a more sustainable future. One of the most popular ways to recycle scrap steel is by using double-shaft shredders to process it. Double-shaft shredders are powerful machines that can handle large volumes of scrap steel and reduce it to manageable sizes for further processing. Double-shaft shredders feature two counter-rotating shafts fitted with blades that shred scrap steel into smaller pieces. The blades on each shaft are positioned in a way that maximizes efficiency and minimizes downtime. The machines are designed to handle a range of scrap steel materials, including cars, appliances, household goods, and industrial waste. The shredded steel can then be fed into a furnace for smelting, or it can be processed further into other steel products. Using double-shaft shredders to process scrap steel has several advantages. Firstly, it reduces the pressure on the mining industry to extract more iron

Aluminium Scrap Recycling Process

2022-08-21Aluminum is one of the metals with the highest recovery rate and the largest demand in the world. The energy used for recycling waste aluminum is only 5% of the new aluminum from its ore bauxite, which is a very cost-effective and environmentally friendly business. Moreover, aluminum is infinitely recyclable, which means that it can be recycled repeatedly without losing the corresponding quality. Aluminum and aluminum alloy products are widely used in our daily life, such as cans, doors and windows, electronic products, building templates, automobiles, etc. In recent years, the demand for aluminum in the world has gradually increased, and the price of aluminum has also experienced several rounds of increase. It has become an urgent task to improve the recovery of aluminum. So, what are the waste aluminum recovery processes and what equipment are needed? Let AIShred give you a brief introduction. Aluminium Scrap Recycling ProcessThe recycling of aluminum scrap is not a complicated process. It is a mature