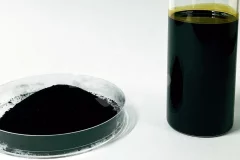

Carbon black is one of the important products of tire pyrolysis, accounting for 30%-35% of tire pyrolysis products, second only to pyrolysis oil. The calorific value can reach 7000 kcal, which is equivalent to coal. After being made into carbon black balls by a briquette machine, it can replace coal in industrial combustion. In addition, it can also be further processed and refined into powder to continue to emit light and heat in other industries. After deep processing, carbon black has many uses and plays an extremely important role in the rubber industry, plastic industry, coating industry, ink industry, environmental protection industry and construction industry. Application Areas1. Rubber industryIn the production of rubber products, carbon black after deep processing can widely replace some traditional industrial carbon black, such as N330, N550, N660, etc., due to its excellent reinforcing properties. It can significantly improve the wear resistance, aging resistance and overall mechanical properties

In the field of tire pyrolysis, batch pyrolysis equipment is popular because of its high efficiency and flexibility. For tires with a diameter of less than 1.2 meters, the whole tire can usually be directly put into the pyrolysis equipment for processing. However, in practice, many customers tend to shred the tires first and then send them to the batch pyrolysis equipment. Recently, our company received a customer from New Zealand, who clearly stated that he hoped to pre-shred the tires before pyrolysis in the hope of higher pyrolysis efficiency. In response to the needs of this customer, our company recommended a production line configuration consisting of a hydraulic tire bead separator, a double-shaft shredder, and an inlet and outlet conveyor. This equipment can shred tires to a size of about 100 mm, which is very suitable as a feed for batch pyrolysis equipment.So, why do some customers choose to pre-shred tires before sending them to pyrolysis equipment? The following is a detailed comparative analysis

Currently, waste tire pyrolysis and oil refining equipment mainly comes in two types: batch and continuous. When selecting pyrolysis and oil refining equipment, companies often face the dilemma of choosing between batch and continuous equipment. Below, we will compare these two types of equipment in detail from key perspectives such as production efficiency, material requirements, environmental performance, automation level, and cost and return on investment, to help you make a more informed decision. 1. Production Efficiency Batch equipment operates in a batch processing mode, handling a batch of waste tires at a time. After each batch is completed, the equipment needs to be shut down for cooling, discharging products and residues, and then starting the next batch. Although this mode is simple to operate, the frequent start-stop cycles result in shorter effective operating times and lower production efficiency. Continuous equipment, on the other hand, enables 24-hour uninterrupted production. Raw materials

What Are the Characteristics of Quality-Compliant Tire Pyrolysis and Oil Refining Equipment?

2025-02-27Under the global background of resource recycling and environmental protection, waste tire pyrolysis and oil refining equipment has become crucial for processing waste tires and achieving resource reuse. For buyers, understanding the features of qualified equipment is vital. 1. Efficient Pyrolysis PerformanceQualified equipment typically adopts advanced pyrolysis technology, capable of precisely controlling temperature, duration, and pressure parameters during pyrolysis. The rational reactor design ensures thorough pyrolysis reactions, maximizing the conversion of organic components in waste tires into fuel oil, carbon black, and combustible gas. With high pyrolysis efficiency and rapid processing speed, it can handle large quantities of waste tires within short timeframes, enhancing production efficiency. 2. Reliable SafetySafety serves as a critical quality indicator. Premium equipment integrates comprehensive safety protections including overpressure protection, overtemperature alarms, and explosion-proof

Tire pyrolysis oil is one of the main products obtained from the pyrolysis of waste tires. Tire pyrolysis oil has a wide range of uses, and its market sales depend on various factors, including market demand, price competitiveness, and product quality. Let's take a closer look below. Main Uses of Tire Pyrolysis Oil1. Industrial FuelPyrolysis oil can be used as an alternative fuel in industrial boilers, cement plants, steel mills, and other industrial facilities that require large amounts of heat. Due to its high calorific value, tire pyrolysis oil can serve as a substitute for diesel or heavy oil, used for heating or power generation.2. Chemical Raw MaterialIn some cases, tire pyrolysis oil can be further processed into chemicals, such as solvents or raw materials for synthetic resins. It can be used to produce chemical products like plastics, rubber products, paints, and coatings.3. Blending DieselIn some countries and regions, tire pyrolysis oil can be blended with other types of fuel to produce diesel

Fully Continuous Pyrolysis Reactor for Sale

2025-02-08The GEP ECOTECH's fully continuous pyrolysis reactor is manufactured according to the production standard of pressure vessels, using an 18mm thick special boiler steel plate, which ensures its ability to withstand high pressure and high temperatures.The reactor features a double-section furnace connection design, further enhancing its durability under extreme conditions. The welding process is performed using automatic inclined side bevel arc welding, which significantly reduces the risk of cracking and ensures a longer service life.The external insulation layer is composed of steel plate, lightweight castable, ceramic knitted blanket, and refractory bricks. With an insulation thickness of up to 350mm, the reactor retains heat efficiently, improving thermal performance and overall energy savings.BenefitsEnhanced Durability: The use of high-quality materials and advanced manufacturing techniques ensures the reactor's longevity and resistance to wear and tear.Energy Efficiency: The superior insulation design

Tire pyrolysis refers to the process of using high temperature to induce thermal chemical reactions of organic substances in waste tires under specific anaerobic or hypoxic conditions, resulting in the decomposition and conversion of high molecular compounds in tires into low molecular substances. Its essence is to break the chemical bonds of large molecules such as rubber in tires through heating, causing them to break down into small molecule substances. So what are the specific products of tire pyrolysis? What are the applications of these products? Let's take a look together below.1. Refining tire oil:It is the substance that produces the most amount of refined tire oil. Engineering tires, truck tires, etc. can produce 45% -50% refined tire oil, while small car tires, motorcycle tires, etc. can produce 35% -40% refined tire oil. It has a high calorific value, generally around 10,300 kcal, and can be used as an alternative fuel for boiler, steel plants, etc. It can also be refined to produce non-standard

Theoretically, the oil yield of waste tire pyrolysis can reach 45% - 50%, that is, about 450 to 500 kilograms of tire oil can be refined from one ton of waste tires. However, in the actual production process, the oil yield often decreases, mainly affected by the following factors. 1.Tire typesTires of different types vary in material, structure and oil content. For example, large engineering tires, truck tires and steel cord tires generally have a relatively high oil yield due to their high manufacturing specifications and good quality. These tires have a high rubber content and better rubber quality, so they can produce more fuel during the pyrolysis process. In contrast, ordinary car tires, motorcycle tires and bicycle tires have a lower oil yield because they are used with lower intensity and the specification requirements during manufacturing are not as strict as those of steel cord tires. In addition, the degree of tire wear also affects the oil content and thus the oil yield.2.Equipment and

What Are the Documents and Related Procedures Required for Tire Pyrolysis and Oil Refining Project

2025-01-26As an expert in solid waste disposal, GEP ECOTECH has rich experience in tire pyrolysis and oil refining disposal. Let's have a look together the documents and related procedures required for a tire pyrolysis and oil refining project.1. Relevant Documents for Business Registration1) Business License: Register the enterprise with the local market supervision and administration bureau, determine the enterprise name, business scope, registered capital and other information, which is the basis for legal operation.2) Tax Registration Certificate: Handle tax registration for tax declaration and payment, determine the tax identity and payment method of the enterprise.2. Project approval certificateProof of Project Filing: Submit a project proposal or feasibility study report to the local Development and Reform Commission, explaining the background, significance, construction content, investment scale, etc. of the project, complete the project filing, and obtain permission to carry out the project.3. Environmental

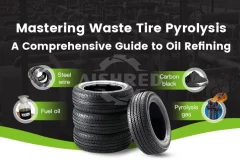

Discover the process of waste tire pyrolysis and oil refining. Learn how thermal cracking transforms tires into valuable resources like tire oil, carbon black, and pyrolysis gas. Explore different technologies, benefits, and applications for sustainable recycling solutions.

How does Waste Tires Realize the Transformation of Their Value Through Pyrolysis Technology?

2025-01-22As a common waste, waste tires have brought considerable pressure to the environment for a long time due to their difficulty in degradation and possible release of harmful substances. However, with the continuous development of pyrolysis technology, it can not only reduce the pollution caused by waste tires to the environment, but also realize the transformation of the value of waste tires. So, next, let's take a look at how waste tires realize the transformation of their value through pyrolysis technology. Pyrolysis technologyPyrolysis is to heat waste tires to a certain temperature under anaerobic or oxygen-deficient conditions, so that they are decomposed into pyrolysis oil, carbon black, steel wire and combustible gas. This method can not only effectively reduce the volume of waste tires, but also realize the recyclable use of resources. Pyrolysis products and their uses1. Pyrolysis oilPyrolysis oil of waste tires is the core product of waste tire pyrolysis and can be directly used as industrial fuel for

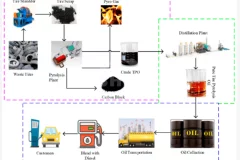

Tire pyrolysis and oil refining is a process of converting waste tires into valuable substances through pyrolysis technology. So what is the overall process like? Let's learn about it together, and see what GEP ECOTECH says.Firstly, Pre-treatmentRemove metal parts, large debris, etc. from waste tires to prevent equipment damage and improve operational efficiency. For continuous production lines, it is also necessary to shred waste tires into rubber chips or grind them into rubber powder.Secondly, FeedingBy manual or mechanical means such as screw feeders, hydraulic feeders, lifting winches, the pre-treated tires or rubber powder are fed into the pyrolysis furnace and the furnace door is closed to ensure high-temperature heating in a sealed environment.Thirdly, Pyrolysis ReactionHeating the pyrolysis furnace under anaerobic or hypoxic conditions, at a certain temperature and pressure, causes the rubber and organic matter in the tire to undergo pyrolysis. The general temperature control is between 160℃ and 700

Tire Pyrolysis System

2025-01-13Tire pyrolysis systems offer a comprehensive and high-level recycling solution for end-of-life tires by using high temperatures in a low-oxygen environment to decompose rubber into valuable byproducts such as tire pyrolysis oil, pyrolysis gas, and carbon black. The system typically consists of a reactor (kiln), oil-gas condensation equipment, and a flue gas purification device. Pre-treatment systems may be required in some cases to process tires into suitable sizes.GEP ECOTECH offers two types of tire pyrolysis systems: batch systems and continuous systems. Batch systems are ideal for smaller-scale operations and applications requiring high flexibility, capable of processing whole tires directly. They offer lower initial investment costs and simpler operation. Continuous systems, on the other hand, are designed for large-scale, continuous production, achieving maximum conversion efficiency with pre-treated rubber powder. They offer higher throughput and automation but require a larger initial investment.GEP

Tire pyrolysis oil refining has become increasingly popular due to its simplicity and high profitability. Many tire recycling companies are adopting or exploring this technology as it not only generates valuable oil from waste tires but also reduces environmental impact. Its flexibility to integrate seamlessly with existing recycling lines makes it an efficient choice for production expansion. Additionally, the process helps lower dependency on fossil fuels by creating alternative energy sources, aligning with global sustainability goals.Price of Tire Pyrolysis Production LineWhen it comes to tire pyrolysis oil refining systems, the cost is a major concern for both newcomers and experienced recyclers. However, the price can vary significantly depending on the system's configuration and capacity. To help you better understand, let’s explore the different types of pyrolysis systems and their general price ranges.Batch-Type Pyrolysis SystemThe batch-type pyrolysis system is the go-to choice for most entry-level