With the continuous development of modern industry, the number of various hazardous wastes is increasing, and a variety of hazardous wastes have a variety of dangerous characteristics, including radioactive, infectious, corrosive, flammable and explosive, chemical reactive and toxic, hazardous waste disposal industry ushered in a period of rapid growth. Data show that the existing capacity of hazardous waste is mainly for comprehensive utilization of resources, and the capacity gap of harmless disposal of hazardous waste in China alone is about 20 million tons/year. If hazardous waste is not properly disposed and managed, it can easily pollute the environment and seriously affect human health and the ecological environment. This kind of hazardous waste harmless treatment has been widely used, hazardous waste harmless treatment in the beginning is shredding treatment, for example: IBC ton drums, 200L iron drums, plastic drums, ton bags, paint drums broken to reduce the volume, easy to follow the treatment,

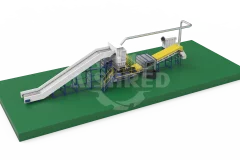

Recycling of old corrugated cardboard has been a long-standing problem. Many of the materials currently on the market are still collected and packaged directly for sale, but in fact further processing of this material - into recycled paper , will have greater added value. Our complete disposal process is approximately: double-shaft shredder (as pre-shredding, discharge size about 15-20cm) + single shaft shredder (used as fine shredding, discharge size about 3cm) + magnetic separator + wet dust removal + pulse dust removal.The low-speed, high-torque double-shaft shredder allows for better capacity reduction of the material, and with the single-shaft fine shredder, the material can be processed to the desired discharge size of the customer.The magnetic separator can pick out the adulterated metal inside the material, after removing most of the metal, one way can sell it directly to increase the added value, and the other can protect the shredder cutters.Both wet and impulse dust removal ensure a high degree of

Waste Shredding Plants for Sale New Zealand

2022-07-01New Zealand attaches particular importance to the circular economy and sustainable development, which ensures that the natural environment throughout the country does not deteriorate and is getting better and better. However, the wastes caused by human activities will always have an impact on the environment, such as urban domestic waste, waste tires, plastics, industrial and commercial waste, etc. These constantly generated waste should be shredded by a waste shredder, and then sorted and recycled. Why Waste Shredding Plant?In the waste management industry, shredding first, then recycling is the motto, shredding provides easier handling of recyclable waste, thereby encouraging more consistent recycling. For example, in the treatment of municipal solid waste, the material is shredded by a shredder, and subsequent operations such as magnetic separation, air separation and anaerobic fermentation can be completed.AIShred Waste Shredding Plant for SaleAIShred is a manufacturer of industrial shredders and a

GV series intelligent tower type hazardous waste shredding system is a set of intelligent, modular and one-stop hazardous waste pretreatment scheme independently developed by AIShred. It integrates lifting system, storage bin, safety protection system, shredding system, fire protection system, intelligent control system and maintenance system, which can provide professional and intelligent shredding process for customers. One of our customer from East Asia bought our GV series tower type hazardous waste shredding system to process contaminated IBC tank and steel drum, the shredding system working very well obtained the high praise from the customer. Application of the hazardous waste shredding systemHazardous waste "rotary kiln - waste heat boiler" disposal system;Cement kiln co-disposal;SMP (shredding - mixing - pumping) system;Battery recycling;Fuel/chemical drum, IBC tank, etc. Industrial wasteAdvantages of the hazardous waste shredding systemSystem integration process, overall safety and environmental pro

Although affected by economic fluctuations, Türkiye is still one of the fastest-growing economies in the world. The government has formulated and implemented ambitious plans for Türkiye's economic development.Türkiye's industry is developed, the urbanization rate is close to 80%, and there are many wealthy people, which will lead to a large amount of solid waste, landfill pollutes the environment and wastes a lot of non-renewable resources. Reuse, Reduce Recycle(3R) is currently the three most critical words in the field of solid waste treatment. Reuse refers to the reuse of undamaged items; reduce refers to reducing the amount of waste, which can reduce landfill consumption; and recycle refers to resource recycling, which converts discarded garbage into renewable products or energy.You need a shredding and recycling plant to complete the 3R mission.GEP ECOTECH provides shredding and recycling systems in Turkey that can be used to process various solid waste materials such as municipal solid waste,

Waste Shredding Plant for Sale in Oman

2022-05-11Waste shredding plant for sale in Oman can be customized according to the needs of customers and can be used in higher volume projects with higher capacity models. Shredder plant is a cost-effective investment tool and can be developed later by adding and removing equipment. Waste shredding plant for sale is offered for sale in AIShred with its fixed and mobile options as well as compact option that is the perfect combination of the two. Stationary waste shredding plants are ideal for large industrial projects. Mobile and compact waste shredding plants provide significant advantages by avoiding waste of time and money in the case of use in several projects.AIShred Waste shredding plant for SaleWaste shredding plants for sale is a machine preferred for being versatile, low investment cost and lowering operating costs by companies operating in the waste management industry or who want to meet their needs for their processing projects. AIShred, one of the leading waste shreddder manufacturers both in China and

Small Waste Shredding Machine for Sale

2022-05-11AIShred has vast experience in designing and manufacturing of industrial shredders for the processing of solid waste both for waste management companies and companies that generate waste. AIShred has production of industrial shredders more than 10 years, which allows it to assert that choosing them as your supplier of this equipment, you choose reliability and quality. The proposed GD3 shredder model is optimally suited for companies that have small generation of waste and other waste requiring further shredding, as well as for enterprises engaged in the processing of waste with small amounts of processing. The shredder is compact and easy to transport if necessary. Also, this industrial shredder can be equipped with a conveyor, magnetic and other cleaning separators. Shredders are designed and manufactured by AIShred and if you wish, you can always come to our production and see one of the shredder models in assembly and in operation. In the production of shredders, we use high-quality components and

Waste Tyre Shredding Machine for Sale

2022-04-24The GDT series tire shredder is a unique tire crushing machine designed specifically for recycling tires from trucks, agricultural and special equipment, aircraft and car wheels. The shredder has a built-in grate that allows you to calibrate the output material (rubber chips) by size.Distinctive features of the tire shredding machine from GEP ECOTECH are compactness, power, as well as an integrated unloading system with the ability to adjust the size of the outgoing fraction using grates.Productivity Capacity - up to 30 tons per hour.The Tire Shredder GDT series can use a hydraulic drive. Such a drive is necessary for tearing a metal cord (metal cord), which is made from a very elastic and hard metal.LOW MAINTENANCE COSTSGEP ECOTECH has developed a new tire shredder concept with a double rotor and low maintenance costs. The cutting blades are made of high quality wear resistant steel. The design of the rotor and blades allows very fast replacement during maintenance. The cost of knives is quite low due to

Waste Management Shredder for Sale Vietnam

2022-04-22Industrial shredders for all materials for sale in Vietnam are automated or semi-automated machines that process waste and materials before disposal or recycling. It used in several sectors, like landfills, cement plant, waste-to-enery plant, MSW sorting plant, paper mills and so on. AIShred industrial shredder, efficiently processes cardboard boxes, plastic packaging, wooden crates, glass, metal cans and mixed waste and reduces the volume of waste by up to 90%! AIShred shredders are strong, sturdy and resilient, but it is also very safe, easy to handle and clean! It is equipped with a gear motor, mobile knives in treated steel and a removable rack for optimal waste compaction and long machine life. Many adaptations are available. AIShred industrial shredder that can process a wide variety of materials commonly found in Vietnam including cardboard, paper, crates, boxes, aluminum cans, PET/HDPE, tin cans, polystyrene, glass and building materials. Our experts can help you choose the best industrial shredder

Bulky Waste Shredder for Sale

2022-04-18Bulky wastes are bulky items such as old furniture, mattresses, sports equipment, rugs, kitchen utensils, decorative accessories or any other item that cannot be disposed of with household waste due to its large size. The newer bulky waste can be reused after repair, and the bulky waste with no repair value can be completely shredded by Industrial bulky waste shredder, and then recycled metals, the plastics, textiles, leather, and paper can be recycled or made into RDF. AIShred designs and manufactures a variety of low-speed, high-torque industrial shredders for size reduction and recycling of solid, bulky waste of nearly all sizes. We have a shredder specially developed for shredding bulky waste, which has more than 200 units installed worldwide and is in good condition AIShred shredders can shred bulky wastes like sofa, mattress, pallets, tables and chairs into small pieces ,this way will reduce its volume and easy to transport.ModelCapacity(m³/h)Output Szie(mm)Dimensions(mm)GDL45010-20100~3004000×1750×

Mini Industrial Shredder for Sale

2022-04-14The MicroShred, our mini industrial shredder, efficiently processes various materials and reduces the volume of your waste by up to 90% of its initial volume! The MicroShred is, as its name suggests, strong, sturdy and resilient, but it is also very safe, easy to handle and clean! It is equipped with a gear motor, mobile knives in treated steel and a removable rack for optimal shredding of waste and long life of the machine.Optimal FeaturesPROVEN TECHNOLOGY: Based on over 50 years of experienceSECURITY: Protective grids and hopper articulated by loading push armQUICK WASTE LOADINGPOWERFUL ENGINEEASY CLEANING: Cleaning is done by simply reversing the knivesCOMPACT DESIGNAdvatangesIncreased productivityImproved internal and external logisticsSafe and comfortable working environmentMore cost effective waste management and increase in revenue from the sale of recyclable materials

Pre-processing of Solid Waste

2022-04-12The processing of solid waste usually consists of various mechanical processes, which serve to change the physical and fuel properties of the waste input and its composition in such a way that subsequent processes and possibilities of the waste utilization can be improved. The minimum technical equipment for efficient treatment includes the following installations:Storage and loading facilitiesRemoval of impurities and foreign matterPre-shreddingSolid Waste Treatment ProcessStorage and LoadingShallow bunkers or deep bunkers receive the delivered waste. Bulky impurities can be roughly removed in the flat bunker with the help of wheel loaders or special grabs. Irrespective of this, the delivered waste can be checked here without any major problems. Problematic deliveries can be excluded from the treatment. Furthermore, the separate storage of different fractions (e.g. dry commercial waste, bulky waste, wet household waste) is easier to realize in flat bunkers. They are cheaper than underground bunkers, but

Municipal solid waste (MSW) is household, commercial, and / or institutional solid waste. They consist of everyday items such as paper, grass clippings, plastic bags, furniture, clothing, bottles, rubber, metals, food waste, paints and batteries. They are not only of domestic origin, but also commercial (offices, retail and wholesale, restaurants), institutional (libraries, schools, hospitals, prisons) and industrial (packaging and administration). Most of them are classified as not dangerous. As part of their solid waste management plan, almost all countries are promoting source reduction, recycling and composting to reduce landfill disposal. Several countries have also adopted specific measures for the disposal of certain materials: leaves, grass clippings, yard waste, office waste and computer paper, newsprint, cardboard and corrugated cardboard, glass, plastic, aluminum and steel containers are prohibited in disposal plants. Many plants burn municipal solid waste at high temperatures not only to reduce

Waste-to-Energy (WtE) plants treated around 420 million tons of waste per year worldwide1. Thanks to the production of energy through waste incineration, WtE plants allow materials to be recovered and recycled. decrease the amount of waste sent to landfills and reduce the proportion of fossil fuels used as a source of energy production.Waste to RDFWaste shredding plant processes overproduction, bulky waste fractions, large packaging and unsorted commercial waste by transforming them into waste-derived fuels (RDF) in various qualities. These fuels can be sent to waste incineration plants, cement plants, steel plants, etc., to obtain certain economic benefits.Waste to Fuel PelletBy pelletization we mean the process of transforming waste, generally into pellets, to make it usable for other applications. To be transformed into pellets, the waste must first be shredded, crushed or pulverized. The materials thus obtained are then processed in a rotary drum or disc pellet machine with the aid of a binding agent,

The proliferation of electronic products has brought with it the issue of disposal of obsolete electronic products. E-waste resource disposal has become a topic of great concern. The method implemented for the recycling of e-waste is physical shredding, and after the shredding and sorting of the e-waste disposal production line, the recycling rate of e-waste is greatly improved. E-waste is a huge hazard, but the value of recycling is also quite large. If after concentrated processing, a relatively high level of renewable resources can be separated, such as copper, iron, aluminium and gold and silver and other metal substances. Waste circuit boards contain up to 60% of metals, of which copper is more, in addition to gold, silver and tin and other rare metals. AIShred intelligent electronic waste shredding and disposal line is a professional intelligent solid waste shredding equipment designed for electronic waste materials, through the European CE certification, the dynamic knife is made of high wear-

Green waste and biomass refers to wastes from animals and plants, which do not need to be wasted and can be converted into fuel or fertilizer. With AIShred's shredding systems, these wastes can be efficiently disposed of for biomass fuel, aerobic/anaerobic fermentation or other further processing requirements. As shown in the picture above, the waste from urban arbor pruning can be shredded into pieces using an industrial shredder and sent to biomass power plants for incineration and power generation. AIShred Twin-Shaft Shredder is a ideal machine to process green waste and biomass.Twin-Shaft ShredderThe twin shaft shredder have two rotating shafts, which allows them to process very hard and large materials. Due to the high strength of the knives and the hexagonal shaft system, they are able to shred hard and tough materials, such as cellulose and lignin. All shredders are supplied with an automatic load control system and shaft speed control with reverse rotation. When the load is exceeded, the system