A single-shaft shredder can be used to shred both new and used carpet materials. These machines are designed to efficiently reduce various types of materials, including carpet, into smaller pieces. Here's how a single-shaft shredder works and the considerations for shredding carpet:Working Principle of single-shaft shredderFeed Hopper: The carpet material is fed into the shredder through a feed hopper.Single Shaft with Rotating Blades: In a single-shaft shredder, there is a single rotating shaft equipped with sharp blades. As the shaft rotates, the blades cut and tear through the carpet material.Screen or Grate: Some shredders may include a screen or grate with specific hole sizes to control the output size of the shredded material.Output Conveyor: The shredded carpet pieces are discharged through an output conveyor, container, or directly into a collection bin.Considerations for Shredding CarpetMaterial Preprocessing: Before feeding carpet into the shredder, it's advisable to remove any non-carpet materials

Textile waste management is a pressing issue in today's society due to the increasing consumption and disposal of fabrics. Single-shaft shredders have emerged as a viable solution for efficiently processing textile waste. In this article, we will explore the optimization of using a single-shaft shredder in textile waste management, considering its benefits, operating parameters, and potential challenges.1.Benefits of Single-Shaft Shredder1.1 Increased Efficiency: The single-shaft shredder offers high-speed processing capabilities, effectively reducing textile waste into smaller fragments.1.2 Versatility: It can handle various types of textile waste, including woven fabrics, non-woven textiles, and garments.Resource Recovery: Shredding textiles can facilitate the extraction of valuable materials, such as fibers, that can be recycled and reused.1.3 Space and Energy Saving: Single-shaft shredders are compact, requiring minimal space, and they operate with low energy consumption compared to alternative textile

The disposal of discarded clothes and shoes has become a significant environmental concern, prompting the need for effective waste management solutions. A big shredder machine designed for processing clothes and shoes can play a vital role in reducing waste volume and facilitating recycling. This article outlines the key considerations when selecting a large shredder machine for clothes and shoes, ensuring efficient and sustainable waste management practices. 1. Material Diversity: Clothes and shoes can comprise various materials such as fabrics, plastics, metals, and rubber. A large shredder machine should be capable of processing this diverse range of materials effectively. Look for a shredder that can handle different materials to ensure versatility in waste processing. 2. Shredding Capacity: The capacity of the shredder is crucial, especially when dealing with large quantities of clothes and shoes. Consider the volume of waste generated daily and select a shredder with the appropriate capacity to match

With the rapid development of leather industry, a large number of leather offcuts also caused serious waste of resources and environmental pollution. Especially in the textile, garment, footwear industry is more developed areas, industrial parks pile of leather, cloth offcuts everywhere, bringing serious environmental problems, social problems and government burden. The tannery industry produces a large amount of waste rubber raw materials every year. As a traditional industry with high input and low output, 30% of raw materials in the tanning industry end up as waste in its production process. According to statistics, India discharges about 150,000 tons of tanning waste every year, and the United States has 60,000 tons. And China is a big tanning country, throwing in nearly 200 million pieces of leather every year, which will produce 1.4 million tons of waste. Every year, there are a lot of leather, fabric, shoes, fabric offcuts are casually discarded, which not only causes serious environmental pollution,

With the development of the economy, the number of waste textiles eliminated by residents has gradually increased, sporadic treatment cannot meet the production requirements, and a sustainable industrial waste system is urgently needed to help us explore together. Today, let's talk about the energy recovery of waste textiles. Because of the addition of comprehensive materials, the thermal value of the waste textiles is very good and the combustion is good. Therefore, it has great potential for incineration power generation and cement kiln. As the energy recovery of waste textiles, we must use industrial waste shredding to deal with the production line. Only through the disposal of this production line can we meet the energy recovery of waste textiles. So what is this industrial waste system? First of all, the core equipment of this system is shredding+sorting, and the connection system is conveying. The purpose of broken is to fully shatter, shear and crushed materials. First, ensure that the material can be

With the improvement of people's living and consumption, the use cycle of textiles is becoming shorter and shorter, and the recovery, treatment and utilization of waste textiles have reached a point that cannot be ignored. AISHRED focuses on solid waste crushing equipment, and has its own unique disposal plan for the recycling and reuse of various solid waste, including waste textiles. Now let's briefly discuss the recycling methods of waste textiles.Sources of Textile WastesThe so-called waste textile mainly refers to the waste short fiber, waste yarn, silk return, leftover material, etc., as well as the waste textile clothing and its products produced in the production process. Waste textiles mainly come from two aspects: one is from production enterprises, which will produce waste staple fiber, waste yarn, silk return, waste cloth noil, etc. in various processes of spinning, weaving and finished product production and processing. On the other hand, it comes from discarded textiles in daily life, such as

Waste Textile Shredders for Sale to Malaysia

2022-07-30There are many kinds of waste textiles, which are usually divided into: waste fiber, waste cotton shavings, waste cloth, waste fiber and other mixtures of cotton and cloth, waste man-made fiber, waste leather, leather shaving mixtures, etc. These materials have high recycling value. Recently, our company has successfully signed a contract with a customer of a garment factory in Malaysia on the disposal of waste textiles. The main equipment includes GD6 double shaft shear shredder, GSS20 single shaft fine shredder, belt conveyor, iron separator, GI intelligent control system, etc., which are used to make RDF molding fuel and power generation in power plants. Simplest Recycling Method of Waste Textiles: Energy RecyclingAt present, the simplest recycling method of waste textiles is energy recycling, that is, crushing the waste textiles that cannot be reused, mixing them with other crushed solid waste materials to make RDF alternative fuels with high calorific value and low carbon emissions relative to fossil

Affordable Single Shaft Shredder for Sale

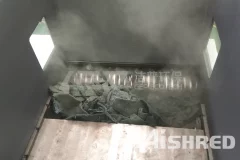

2022-04-08The GSS series single shaft shredder is the perfect machine for the fine shredding sector: thanks to the trapezoidal blades and the reduced rotation speed, it is able to guarantee excellent performance in terms of energy consumption, production and maintenance. The structure of the machine is made up of very thick electro-welded sheets, such as to guarantee sturdiness and reliability over time. The shredding takes place through the cutting action of the rotating blades on the fixed blades which are mounted on an adjustable crosspiece. A pusher also guarantees the grinding of bulky items, avoiding floating phenomena. The motorization varies according to the requirements of the material to be treated. It is given by a hydraulic motor with relative control unit, keyed to a planetary reduction gear. A screening grid is installed under the rotor. Unlike the shredders already on the market, this machine allows to obtain a ground product with very homogeneous dimensions and defined according to the size of the