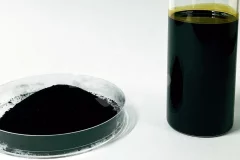

Carbon black is one of the important products of tire pyrolysis, accounting for 30%-35% of tire pyrolysis products, second only to pyrolysis oil. The calorific value can reach 7000 kcal, which is equivalent to coal. After being made into carbon black balls by a briquette machine, it can replace coal in industrial combustion. In addition, it can also be further processed and refined into powder to continue to emit light and heat in other industries. After deep processing, carbon black has many uses and plays an extremely important role in the rubber industry, plastic industry, coating industry, ink industry, environmental protection industry and construction industry. Application Areas1. Rubber industryIn the production of rubber products, carbon black after deep processing can widely replace some traditional industrial carbon black, such as N330, N550, N660, etc., due to its excellent reinforcing properties. It can significantly improve the wear resistance, aging resistance and overall mechanical properties

Waste tires contain bead wires, which, if not removed, may cause increased wear and even damage to equipment such as tire shredders. The use of tire debeader can effectively reduce equipment wear and maintenance costs. At the same time, it can greatly improve the efficiency of waste tire processing, reduce environmental pollution, and increase resource recovery rate, making it an important equipment in the waste tire recycling industry, rubber regeneration, and environmental protection industry. The tire debeader, also known as tyre bead wire remover, tire bead wire puller, or bead extraction machine in some regions, is an essential piece of equipment in the waste tire recycling process. As one of the key tire recycling plants in the pre-treatment stage, it efficiently separates the steel bead wires from tires, preparing them for further processing such as shredding, granulation, or pyrolysis.Applicable Tire SizesThe tire debeader is usually suitable for waste tires with a diameter ranging from 800mm to

Waste tires are known as "black gold". According to statistics, the United States generates approximately 250 million to 300 million waste tires annually, with a total weight of about 3 million tons. If these tires are not utilized, it will be a great waste of resources. Therefore, recycling waste tires has profound significance, as follows:1. Environmental protection1) Reduce pollution: Long term accumulation of waste tires can release harmful substances, pollute soil and water sources, and recycling can effectively reduce such pollution.2) Fire prevention: Waste tires are flammable and can easily cause fires when piled up in large quantities. Recycling can reduce the risk of fires.3) Reducing carbon emissions: Recycling waste tires can reduce the production of new materials, thereby lowering carbon emissions.2. Resource conservation1) Resource reuse: Rubber, steel wire, and fiber from waste tires can be recycled and reused to reduce dependence on natural resources.2) Energy conservation: Waste tires can be

Can Tire Pyrolysis Oil Be Burned Directly?

2025-03-12The oil produced from tire pyrolysis and refining is usually referred to as pyrolysis oil or cracking oil. It belongs to heavy oil and cannot be directly burned. It needs to be further processed before it can be safely and effectively used. The following are specific reasons and solutions:1. Complex Composition1) Impurities: Pyrolysis oil contains impurities such as sulfur, nitrogen, chlorine, etc. Direct combustion can produce harmful gases.2) Instability: The chemical composition of pyrolysis oil is complex, and direct combustion may lead to incomplete combustion, producing black smoke and harmful substances.2. Disposal Method1) Refining: Removing impurities through processes such as distillation and filtration to improve the purity and stability of the oil.2) Desulfurization: Using desulfurizers or catalysts to remove sulfides and reduce the production of sulfur dioxide during combustion.3) Mixing: Mixing pyrolysis oil with diesel or other fuels to improve its combustion performance.3. Application Fields1

What Is Tire Pyrolysis and Oil Refining?

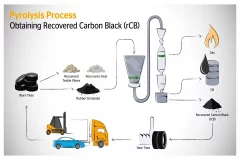

2025-03-08Tire pyrolysis and oil refining is a process of converting waste tires into useful resources such as fuel oil, carbon black, and combustible gas through high-temperature pyrolysis technology. This technology can not only effectively process waste tires, reduce environmental pollution, but also achieve resource recycling. The following are the main processes and key points of tire pyrolysis and oil refining:1. Basic principleHeat waste tires to a certain temperature (usually 300 ℃ -500 ℃) in an anaerobic or low oxygen environment, causing their polymer to undergo pyrolyzing and produce the following products:1) Pyrolysis oil: can be used as fuel oil or further refined.2) Carbon black: can be used in industrial fields such as rubber products and coatings.3) Combustible gas: mainly composed of methane, hydrogen, etc., can be used as fuel for pyrolysis process.4) Steel wire: The steel wire in tires can be recycled and reused.2. Main process1) Tire pretreatmentRemove impurities (such as mud, stones) from the

What Are the Characteristics of Quality-Compliant Tire Pyrolysis and Oil Refining Equipment?

2025-02-27Under the global background of resource recycling and environmental protection, waste tire pyrolysis and oil refining equipment has become crucial for processing waste tires and achieving resource reuse. For buyers, understanding the features of qualified equipment is vital. 1. Efficient Pyrolysis PerformanceQualified equipment typically adopts advanced pyrolysis technology, capable of precisely controlling temperature, duration, and pressure parameters during pyrolysis. The rational reactor design ensures thorough pyrolysis reactions, maximizing the conversion of organic components in waste tires into fuel oil, carbon black, and combustible gas. With high pyrolysis efficiency and rapid processing speed, it can handle large quantities of waste tires within short timeframes, enhancing production efficiency. 2. Reliable SafetySafety serves as a critical quality indicator. Premium equipment integrates comprehensive safety protections including overpressure protection, overtemperature alarms, and explosion-proof

Tire pyrolysis refers to the process of using high temperature to induce thermal chemical reactions of organic substances in waste tires under specific anaerobic or hypoxic conditions, resulting in the decomposition and conversion of high molecular compounds in tires into low molecular substances. Its essence is to break the chemical bonds of large molecules such as rubber in tires through heating, causing them to break down into small molecule substances. So what are the specific products of tire pyrolysis? What are the applications of these products? Let's take a look together below.1. Refining tire oil:It is the substance that produces the most amount of refined tire oil. Engineering tires, truck tires, etc. can produce 45% -50% refined tire oil, while small car tires, motorcycle tires, etc. can produce 35% -40% refined tire oil. It has a high calorific value, generally around 10,300 kcal, and can be used as an alternative fuel for boiler, steel plants, etc. It can also be refined to produce non-standard

Theoretically, the oil yield of waste tire pyrolysis can reach 45% - 50%, that is, about 450 to 500 kilograms of tire oil can be refined from one ton of waste tires. However, in the actual production process, the oil yield often decreases, mainly affected by the following factors. 1.Tire typesTires of different types vary in material, structure and oil content. For example, large engineering tires, truck tires and steel cord tires generally have a relatively high oil yield due to their high manufacturing specifications and good quality. These tires have a high rubber content and better rubber quality, so they can produce more fuel during the pyrolysis process. In contrast, ordinary car tires, motorcycle tires and bicycle tires have a lower oil yield because they are used with lower intensity and the specification requirements during manufacturing are not as strict as those of steel cord tires. In addition, the degree of tire wear also affects the oil content and thus the oil yield.2.Equipment and

What Are the Documents and Related Procedures Required for Tire Pyrolysis and Oil Refining Project

2025-01-26As an expert in solid waste disposal, GEP ECOTECH has rich experience in tire pyrolysis and oil refining disposal. Let's have a look together the documents and related procedures required for a tire pyrolysis and oil refining project.1. Relevant Documents for Business Registration1) Business License: Register the enterprise with the local market supervision and administration bureau, determine the enterprise name, business scope, registered capital and other information, which is the basis for legal operation.2) Tax Registration Certificate: Handle tax registration for tax declaration and payment, determine the tax identity and payment method of the enterprise.2. Project approval certificateProof of Project Filing: Submit a project proposal or feasibility study report to the local Development and Reform Commission, explaining the background, significance, construction content, investment scale, etc. of the project, complete the project filing, and obtain permission to carry out the project.3. Environmental

How does Waste Tires Realize the Transformation of Their Value Through Pyrolysis Technology?

2025-01-22As a common waste, waste tires have brought considerable pressure to the environment for a long time due to their difficulty in degradation and possible release of harmful substances. However, with the continuous development of pyrolysis technology, it can not only reduce the pollution caused by waste tires to the environment, but also realize the transformation of the value of waste tires. So, next, let's take a look at how waste tires realize the transformation of their value through pyrolysis technology. Pyrolysis technologyPyrolysis is to heat waste tires to a certain temperature under anaerobic or oxygen-deficient conditions, so that they are decomposed into pyrolysis oil, carbon black, steel wire and combustible gas. This method can not only effectively reduce the volume of waste tires, but also realize the recyclable use of resources. Pyrolysis products and their uses1. Pyrolysis oilPyrolysis oil of waste tires is the core product of waste tire pyrolysis and can be directly used as industrial fuel for

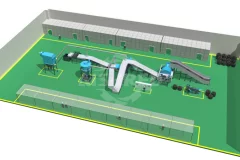

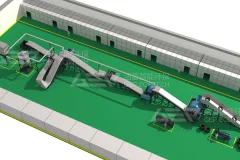

Tire Pyrolysis System

2025-01-13Tire pyrolysis systems offer a comprehensive and high-level recycling solution for end-of-life tires by using high temperatures in a low-oxygen environment to decompose rubber into valuable byproducts such as tire pyrolysis oil, pyrolysis gas, and carbon black. The system typically consists of a reactor (kiln), oil-gas condensation equipment, and a flue gas purification device. Pre-treatment systems may be required in some cases to process tires into suitable sizes.GEP ECOTECH offers two types of tire pyrolysis systems: batch systems and continuous systems. Batch systems are ideal for smaller-scale operations and applications requiring high flexibility, capable of processing whole tires directly. They offer lower initial investment costs and simpler operation. Continuous systems, on the other hand, are designed for large-scale, continuous production, achieving maximum conversion efficiency with pre-treated rubber powder. They offer higher throughput and automation but require a larger initial investment.GEP

Tire pyrolysis oil refining has become increasingly popular due to its simplicity and high profitability. Many tire recycling companies are adopting or exploring this technology as it not only generates valuable oil from waste tires but also reduces environmental impact. Its flexibility to integrate seamlessly with existing recycling lines makes it an efficient choice for production expansion. Additionally, the process helps lower dependency on fossil fuels by creating alternative energy sources, aligning with global sustainability goals.Price of Tire Pyrolysis Production LineWhen it comes to tire pyrolysis oil refining systems, the cost is a major concern for both newcomers and experienced recyclers. However, the price can vary significantly depending on the system's configuration and capacity. To help you better understand, let’s explore the different types of pyrolysis systems and their general price ranges.Batch-Type Pyrolysis SystemThe batch-type pyrolysis system is the go-to choice for most entry-level

Recently, an Australian customer inquired about a 4-6 ton per hour tire pelletizing line, the majority of which are car and truck tires, with diameters of up to 1200mm, and a discharge size of 150mm containing steel wire, to be used as an alternative fuel for cement kilns to burn to generate energy. The client is an Australian company specializing in import and export, providing integrated solutions with financial, environmental and operational objectives for a variety of sectors including industrial and commercial construction. After initial communication, it was determined that the project is currently in the stage of technical improvement and supplier selection, our company according to the requirements provided by the customer and the existing operation of the site problems, to give targeted solutions to address the customer's main concerns and timely provision of equipment programs and quotations. Then it enters the repeated communication link, at present the customer gives high evaluation and

What Would a Tire Granulating Line Be Like?

2024-09-29Recently, a Latin America customer inquired about a 5-ton per hour tire granulation line project, of which 90% are car tires, and the rest are truck tires, tractor tires, bus tires, etc., but the diameter does not exceed 1200mm. The customer's requirements for the discharge particle size are relatively wide, and they have the following applications:1. Around 50x50mm, to be used as a substitute fuel for cement kilns and generates energy through combustion2.<1mm, to be used as rubber powder for fine sand and mortar for construction, or for sewage treatment3. from 2 to 5mm, to be used as a medium: coarse sand for reinforced concrete, paving, and asphalt productionThe client is a turnkey engineering company that provides comprehensive solutions with financial, environmental, and operational goals for various fields such as industry, shopping centers, hospitals, and commercial buildings. After preliminary communication, it has been determined that the project is currently in the feasibility study stage, and our

Tire shredders, also known as tire crushers or tire granulators, are used to reduce tires into smaller pieces, often as part of recycling processes. There are different types of tire shredders, each suited for different stages of processing used tires. Here are some common categories:Primary Shredders: These machines are designed to take whole tires and shred them into large rubber chunks. They typically feature sturdy blades or knives capable of handling tires of all sizes, including those from trucks or construction equipment.Secondary Shredders: After tires have been processed by a primary shredder, secondary shredders further reduce the size of the fragments into smaller pieces, usually a few centimeters in size.Granulators: Granulators are used to produce uniform-sized rubber granules. These machines often come equipped with screening systems to control the size of the finished product.Micro-Granule Shredders: They produce very small pieces of rubber, called micro-granules, which can be used in the

How to Reuse Waste Tires?

2024-03-27There are several ways to reuse waste tires, also known as scrap tires, in an environmentally friendly and economically beneficial manner.Here are some common methods:1. Tire Recycling Plants: These facilities specialize in shredding tires into their original components such as rubber, steel, and fiber. The rubber can be ground into small granulates or powders, which is used in various applications including playground surfaces, athletic tracks, and rubberized asphalt for roads.2. Tire-Derived Fuel (TDF):Tires can be shredded into smaller pieces and used as a fuel source in industries like cement manufacturing and pulp and paper mills. TDF serves as an alternative fuel, reducing the consumption of fossil fuels and diverting tires from landfills.3. Tire Pyrolysis:Pyrolysis is a process that involves heating tires in the absence of oxygen to break them down into oil, gas, and carbon black. The resulting products can be used as fuel, chemical feedstock, or as filler material in various industrial applications.4

The Essential Guide to Tire Shredding

2024-01-31The disposal of used tires represents a significant environmental challenge worldwide. Tire shredding is a fundamental solution to this problem, transforming end-of-life tires into valuable materials for various industries. This process not only helps in managing waste efficiently but also contributes to reducing the ecological footprint of tire disposal.Understanding Tire ShreddingTire shredding is the process of breaking down used tires into smaller, manageable pieces. These pieces can then be repurposed for a variety of applications, ranging from rubber mulch for landscaping to crumb rubber for athletic tracks and fields. The process involves several stages, each designed to reduce tires to a specific size and remove contaminants such as metal wires and synthetic fibers.The Tire Shredding ProcessCollection and Pre-processing: The initial step involves collecting the used tires and preparing them for shredding. This may include inspecting tires for any reusable qualities or removing rims and other non-

Waste tire recycling machine for rubber powder, also known as rubber powder production line, is designed to convert waste tires into rubber powder or granules for various applications. These machines typically go through several stages to process tires into usable rubber powder. Here are some key components and steps involved in the process:Rubber Powder Production Line1. Tire Shredding:Tire Cutter/Shredder: Used to cut or shred tires into smaller pieces or strips, increasing the surface area for subsequent processing.2. Granulation or Grinding:Rubber Crusher/Grinder: Further reduces the shredded tires into granules or fine rubber powder.3. Magnetic Separation:Magnetic Separator: Removes steel wires and other metallic components from the rubber material obtained from the grinding process.4. Fiber Separation (Optional):Fiber Separator: Separates and removes fiber materials from the rubber powder, depending on the desired purity of the final product.5. Fine Powder Processing (Optional):Fine Grinding/Milling

Optimizing the Use of a Double-Shaft Shredder for Processing Waste Tires into Rubber Powder

2023-11-18Introduction:The disposal and recycling of waste tires have become crucial environmental concerns worldwide. One effective approach is the utilization of a double-shaft shredder to process waste tires and convert them into rubber powder. This article aims to discuss the optimization of the double-shaft shredder’s operation for the efficient production of high-quality rubber powder.Selection of Shredder Parameters:To achieve optimal results, several key parameters of the double-shaft shredder should be considered:Shredder Speed: Adjusting the speed of the shredder blades ensures the proper size reduction without excessive energy consumption.Blade Configuration: Choosing the appropriate blade design and spacing enhances the shredding efficiency and minimizes the generation of excess heat.Shredder Capacity: Ensuring the shredder’s capacity matches the throughput requirements guarantees smooth and continuous tire processing.Tire Preparation:Effective tire preparation is essential for maximizing the shredder’s

SBR Granules Production Plant

2023-08-01"SBR" is an acronym for "Styrene-Butadiene Rubber," a synthetic rubber known for its versatility and numerous applications. When enhanced with additives, SBR exhibits exceptional resistance to abrasion and aging, making it a preferred choice in various industries. The popularity of SBR granules has grown significantly due to their diverse uses in engineering and construction projects, as well as their wide application in the production of rubber products, road repair, sports surfaces, tracks, rubber flooring, and more. SBR granules are derived from waste tires or other rubber materials through a straightforward and efficient manufacturing process. The key stages of production encompass shredding, steel wire separation, granulation, and fiber separation. GEP ECOTECH boasts extensive expertise in assisting customers with the design, manufacturing, and construction of rubber granule production lines. Our solutions are meticulously tailored to suit specific requirements, including raw materials, site conditions

The increasing number of cars has resulted in a rise of scrapped cars. Several cities are now constructing industrial parks dedicated to dismantling and recycling these vehicles. While scrapped cars may seem useless, there are still many materials that can be recycled after dismantling. However, the tires of these scrapped cars have become a major problem. Stacking them in a centralized location not only occupies land but also increases the risk of fire, which negatively affects the environment. Fortunately, tires have some recycling value. As such, there is an urgent need for a production line that can turn waste tires into a valuable resource in the market. GEP ECOTECH is a professional supplier of solid waste solutions and equipment. They are able to independently design, develop, and manufacture a waste tire resource disposal production line that is tailored to the characteristics of waste tires and can meet various project disposal requirements. One example is the process of waste tire granulation:

When choosing a tire shredder, you should not only focus on the price, but also on the quality of the equipment. Consider the output, displacement, energy consumption, and choose a more suitable tire shredder equipment from the many tire shredder brands. What factors need to be considered when selecting a tire shredder?The characteristics of the material to be disposed ofWhen choosing a tire shredder, the selection should be based on the nature of the actual material to be processed. Different models of tire shredder equipment have different production capacities and can handle different materials. These differences have also become the criteria for distinguishing tire shredder equipment models. For example, to deal with large truck tires, choose a large tire shredder equipment. Equipment CapacityDifferent types of tire shredders have different unit processing capacities, and different tire shredder equipment consumes different amounts of energy in the process, so the operating costs are different. It is

The Recycling of Waste Tires

2023-02-09With the rapid development of the automobile industry and the increase of cars, the number of scrap tires produced each year is also increasing. According to statistics, the world is expected to produce a total of about 2.35 billion tires in 2021, and the number is increasing year by year, causing serious harm to the environment. And scrap tires are treasures everywhere, and can be recycled after treatment, so the treatment of scrap tires is not only environmentally friendly but also has huge economic benefits. There are three main directions of reusing waste tires:Waste tire cement kiln co-disposal: With the continuous increase of coal price and the implementation of double carbon policy, cement enterprises start to layout alternative fuel projects for waste tires, which is a very good high calorific value fuel that can save cost and reduce carbon emission.Thermal cracking of waste tires: The steel wire, carbon black, fuel oil and combustible gas after thermal cracking of waste tires can be obtained. These

Waste Tyre Recycling and Disposal Process

2023-02-07As an essential material in people's daily lives, waste tyres are increasingly becoming a disposal problem with the development of the automotive industry. The tyres themselves are highly utilisableThe following are the two most common tyre recycling processes.Pyrolysis: Pyrolysis is one of the most thorough methods of treating automotive waste rubber. Cracking treatment has no pollutant emissions, and can also recover fuel oil and carbon black, which is conducive to environmental protection and resource utilization and has high economic value, and is considered one of the best ways to treat waste tyres at present.Made into rubber powder/particles/blocks: waste tyres are made into rubber powder by normal temperature crushing method, normal temperature chemical method, etc. Rubber powder is widely used in sports plastic sports field, playground, rubber floor tile, waterproofing membrane, waterproof coating, highway modified asphalt, rubber products and other fields. In terms of making rubber powder, we