Recycling old mattresses to produce refuse-derived fuel (RDF) is an effective way to reduce waste while generating an alternative energy source. This process converts mattress components such as foam, textiles, and wood into usable fuel, supporting the circular economy and reducing reliance on traditional fossil fuels.The Significance of Mattress Waste RecyclingMillions of mattresses are discarded each year, and their bulky nature makes them challenging to manage in landfills. Mattresses contain materials like polyurethane foam, steel springs, wood, and fabric, many of which are non-biodegradable. Recycling these components not only prevents landfill overflow but also enables the recovery of valuable materials for other uses, such as RDF production.The RDF Production Process from Recycled MattressesCollection and SortingDiscarded mattresses are collected from households, businesses, and institutions. They are sorted to remove non-recyclable items and contaminants, ensuring a clean feedstock for the recycling

In the pulp and paper production process, will produce a variety of solid waste (i.e., slag), for example, an annual production capacity of 1 million tons of paper mills, the amount of slag accounted for about 10% of the amount of slag, i.e., 100,000 tons / year, which is a large number, and highly concentrated, such as improper disposal, but also cause significant pollution and endanger the ecological environment. The composition of paper production waste is very complex, mainly contains: rope, cotton yarn, cotton cloth, paper residue, wood chips, rubber, plastic, electronic parts, wire, nails, aluminum cans, PE plastic bottles, waxed paper and glass, stone and sand. Paper waste residue can be used to make solid alternative fuels, a utilization that not only reduces waste, but also replaces traditional fossil energy sources and reduces carbon emissions. The plastics in paper production waste can not be degraded, and direct stacking seriously affects the ecological environment. At present, there are paper

What is the price of RDF/SRF?

2024-05-06The pricing of RDF (Refuse-Derived Fuel) and SRF (Solid Recovered Fuel) per ton is a significant concern for investors and users alike. It goes beyond just investment returns, impacting the operational costs of users directly. Much like coal pricing, RDF/SRF pricing varies based on factors such as its source, quality, and market dynamics.RDF-5 PelletsThe U.S. Energy Information Administration website outlines prices for different coal grades and sulfur content, highlighting the disparities in coal pricing. When considering RDF/SRF for fuel application, factors like calorific value, post-combustion emissions, and potential impacts on the environment or end products are crucial. For example, RDF with high chlorine content may affect concrete quality when used in cement kilns.Average weekly coal commodity spot pricesHowever, determining RDF/SRF pricing is more complex than coal pricing. Firstly, there's no specialized RDF/SRF category in the spot or futures market. Secondly, RDF/SRF comes from various sources

When it comes to discarded shoes, many people think about how to properly dispose of them, and one potential solution is to convert old shoes into solid recovered fuel (SRF). Although this may sound surprising, in theory, this approach is possible. Here are some considerations for converting old shoes into solid recovered fuel .Why can old shoes be used as solid recovered fuel ?Discarded shoes contain a variety of materials such as rubber, leather, synthetic fibers and metal trimmings. The processing and utilization of these materials, especially the combustion potential of rubber and synthetic fibers, makes discarded shoes a potential solid recovered fuel .Advantages of using old shoes as solid recovered fuelHigh calorific valueSmall particle sizelow moisture contentManufacturing process of using old shoes as solid recovered fuelPrimary shredding (shred to 30 mm),Screening to remove fine materials (helps reduce moisture content), trommel screen recovery or air density separation to remove heavy components,

Mixed municipal waste contains a large number of recyclable beverage bottles, metals, cardboard and other renewable resources that can be recycled and reused; the content of perishable waste, mainly food waste, accounts for 40-60%, which can be utilized as a biomass energy source; and the largest proportion is still high-calorific-value combustibles, which can be prepared as "alternative fuels (RDF/SRF)" to reduce the use of coal combustion.AIShred, as a manufacturer of solid waste pre-processing equipment, offers a complete range of proven and reliable systems and equipment for the preparation of alternative fuels (SRF) based on the three main pre-processing objectives of mixed domestic/other waste: "sorting of recyclables", "extraction of organic matter", and "preparation of combustible materials for RDF/SRF".The whole set of domestic garbage alternative fuel (SRF) preparation system adopts the automatic process design of "feeding - bag breaking - screening - recycling - crushing - transportation", which

New Breakthrough in Waste Plastic Packaging Film Treatment: Waste Derived Fuel Technology

2023-08-17With the development of the economy and the rapid rise of the packaging industry, packaging waste is also increasing in large quantities, if not dealt with in a timely manner, will seriously pollute the environment, and over time the formation of a vicious and ungovernable trend. At present, the recycling and reuse of packaging waste has become an urgent task of environmental protection in all countries, but also the primary measures to combat global environmental pollution. Especially plastic packaging film, with easy aging, easy to break, short life cycle characteristics, if not handled in a proper way, the environment and the ecosystem will produce great harm. In addition, plastic film and other plastic products to petroleum as the main raw material, with the global consumption and depletion of petroleum resources, including waste plastic packaging film, including the recycling of waste plastics has also become a hot spot for people to study. A large amount of plastic packaging films are discarded

RDF Shredder Machine for Sale, Get Quotation for Your Waste-to-Fuel Solution with one Click

2023-07-22In today's world, the escalating volume of waste has overwhelmed traditional landfill disposal methods, resulting in wasted space and valuable resources. To combat this issue, the conversion of waste into solid fuel has become a popular solution. Two essential products of this process are RDF (Refuse-Derived Fuel) and SRF (Solid Recovered Fuel). These fuels are obtained through advanced shredding and processing techniques that transform waste into valuable energy sources with high calorific value. The waste shredder plays a vital role in this waste-to-fuel transformation process, efficiently breaking down waste materials and creating homogeneous fuel products. RDF and SRF offer sustainable alternatives to conventional fossil fuels, contributing to a more eco-friendly and resource-efficient future.RDF PlantThe RDF (Refuse-Derived Fuel) plant is a specialized facility designed to efficiently convert solid waste into RDF, a valuable solid fuel with high calorific value. The RDF plant's workflow involves several

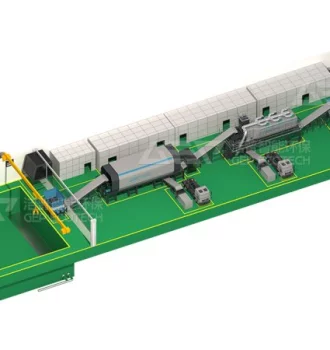

Alternative Fuel System for Cement Industry

2023-07-21With the global demand for cement on the rise, the cement industry faces an imperative to adopt sustainable practices that minimize its environmental impact. In this pursuit, the industry has strategically prioritized the search for alternative fuels, a crucial step towards reducing fossil energy consumption, improving manufacturing processes, curbing pollution, and cutting down production costs. Leading the charge in environmental technology solutions, GEP ECOTECH is at the forefront of driving sustainability in cement production. Their cutting-edge Alternative Fuel System offers a comprehensive and proven technology that efficiently converts various materials with calorific value into engineered fuels. This groundbreaking system incorporates shredding, sorting, screening, conveying, and control mechanisms, ensuring a streamlined and efficient process with an impressive single production line capacity of up to 80 tons per hour. GEP ECOTECH's Alternative Fuel System serves as a game-changer in cement

Straw Pretreatment System for Biopower Plant

2023-06-06Crop straws, like other agricultural and forestry wastes, are widely used biomass energy. Using them as fuel for biomass power plants is one of the popular options. There are many advantages to using crop straws to generate electricity. They usually have a high calorific value, can enter the boiler without complicated treatment, and do not consume carbon emission quotas. To use crop residues and other biomass materials to generate electricity or heat, they just need to be processed to a size suitable for combustion. It's simple, yet challenging. The main reason is that the boiler cannot be turned off, and the fuel must be continuously and stably supplied Using the AIShred biomass pretreatment system, ou can draw on our many years of experience in this field. The system is composed of biomass shredder, chain plate conveyor, belt conveyor, magnetic separator, intelligent monitoring system, and dust collector. It can process biomass raw materials to suitable uniform sizes according to recycling needs. The

Fuel Production From Household Waste

2023-05-22In recent years, the popular term "RDF" in the field of solid waste refers to waste derived fuels, and most environmentalists have also turned their attention to the field of household waste. The composition of household waste we usually refer to is a mixture of wet waste and dry waste, while in the preparation of fuel for household waste, it is best to make a distinction based on current incineration needs. Frontend differentiation can reduce the investment cost of pre-treatment production lines while also improving the calorific value of materials. In the field of incineration, calorific value is a sensitive term. In fact, this process flow is not complicated. Our designed process principles have three positioning points: "impurity removal, reusable selection, and combustible compression". These three process points constitute the equipment solutions applicable in the current field of solid waste disposal. The impurity removal we refer to can be understood as the purification of household waste. There will

Industrial waste realizes its final value in factory production and is hidden in the corners of factories because there is no way to be discarded directly, plus the high price of disposal. In the "double carbon" target, high coal prices, cement companies increasingly hot competition and other comprehensive background, alternative fuels and co-disposal has received more and more attention, the wave of industrial solid waste preparation of alternative fuels was born. AI Shred environmental protection alternative fuel preparation technology can turn industrial solid waste into reusable "coal" energy, industrial waste disposal is no longer a problem!What are the categories of industrial waste?Industrial waste is divided into cloth and leather trimmings from garment factories and shoe factories, waste residue from paper mills and twisted rope braid material, fiberglass trimmings, waste rubber and plastic, etc. From the perspective of resource recycling, these wood materials to leather trimmings, they can all be

How to Deal with Paper Mill Waste?

2023-02-22Do you know how the paper we use every day is produced? Whether it is office paper, living paper, corrugated paper boxes, etc., paper is really important in our life. Traditional paper is produced from pulp. However, with the deepening of environmental protection concepts and the promotion of environmental protection policies, recycled paper has been slowly replacing traditional pulp paper. The rise of recycled paper has great significance for environmental protection and resource recovery. However, in the process of recycled paper making, a large amount of paper mill waste will be produced. According to statistics, the paper mill waste produced by a recycled paper mill accounts for about 12% of the recycled paper production. For example, a recycled paper mill with an annual output of 1 million tons will produce about 120 thousand tons of paper mill waste every year. If these paper mill residues are not properly treated, they will have a great impact on the environment, thus losing the significance of the

RDF Shredders for Waste-to-Fuel

2023-02-14Derived fuel has the characteristics of high calorific value, stable combustion, easy transportation, easy storage and low secondary pollution, which is widely used in drying engineering, cement manufacturing, heating engineering and power generation engineering. RDF raw materials mainly come from domestic waste, industrial waste, organic waste, etc. It contains waste paper, hard plastic, metal, glass, wood, rubber and other substances. The coarse shredder and fine shredder meet the crushing requirements of RDF, greatly simplifying the RDF treatment process and realizing high economic and ecological value. Equipment Configuration The crushing of this high mixture of materials places high demands on the crushing technology. The stable operation of the shredder requires high performance alloys and high reliability of the whole machine. This type of crushing requires a machine capable of handling hard materials such as metals and plastics. To obtain a high quality RDF, the following steps need to be performed:

Waste Wood RDF Forming Process

2022-08-23RDF technology is the world's umbrella term for solid waste treatment technologies for small and medium-sized cities with a capacity of 400 to 1,200 tonnes of domestic waste per day. RDF can solve the perplexity of cities with long-standing waste enclosures and is a new technology to replace outdated landfills that pollute air, groundwater and crops. Wood can be found everywhere in life and is obtained in various ways, such as logs, paper mill trimmings, waste and bulky waste(sofas, tables, chairs and benches, etc.). Wood itself has a high recycling value, and with the prevalence of RDF technology today, the recycling and use of wood is becoming increasingly popular. The wood itself has a high calorific value and for the wood RDF forming process, a low speed high torque double-shaft shredder (used as pre-shredding) + chipper + wood shredder + pelletizer (forming machine) is generally used. With some auxiliary equipment such as: chain conveyor, iron remover, negative pressure dust collector, etc. Please feel

Tequila,a distilled beverage made from the blue agave plant, produced mainly in the area around the city of Tequila, 65 km (40 miles) northwest of Guadalajara, and in the highlands of Los Altos de Jalisco, in the state of Jalisco in west-central Mexico.It takes 8-10 years for a mature agave plant to grow, its rootstock is so large that it weighs several hundred kilograms and is known as a "natural brewer".Then, the use of the rootstock goes far beyond that. The agave is squeezed to squeeze out as much of the juice as possible before it is used for brewing, a process that removes roughly 50% of the water from it, while the rest of the material can be shredded, dried and made into biomass pellets to be burned in boilers. AIShred, as a specialist in biomass disposal, has a wide range of shredders to provide material disposal services.We can supply low speed, high torque double-shaft shredders for cutting and shredding materials. The customised cutters are made of NiCrMo imported from Europe for long life and

AIShred RDF&SRF Alternative Fuel Technology

2022-07-12Internationally, Refuse Derived Fuel (hereinafter referred to as "RDF") is regarded as a new way of waste harmless, recycling and reduction. It has been widely used in cement, power generation and other industries. It is green, environmentally friendly, high quality and low price Alternative fuels (SRF/RDF) are the new trend of the future. The preparation of waste-derived fuel RDF is not limited by site and scale. It is suitable for small and medium-sized waste treatment plants to be scattered and manufactured, and then collected for power generation, which is conducive to improving the scale and efficiency of waste-to-energy power generation. Converting waste to waste-derived fuel (RDF) serves two purposes: it can reduce the amount of waste sent to landfills, thereby solving problems in the waste field, and it can supply large coal-fired power plants, waste incineration plants, cement plants Provides a large number of alternative fuel RDF. AIShred RDF&SRF Alternative Fuel Achievement PathAIShred has

Energy Recovery from Municipal Solid Waste

2022-06-06Municipal Solid Waste (MSW) contains organic as well as inorganic matter. The latent energy present in its organic fraction can be recovered for gainful utilisation through adoption of suitable Waste Processing and Treatment technologies. The recovery of energy from wastes also offers a few additional benefits as follows:The total quantity of waste gets reduced by nearly 60% to over 90%, depending upon the waste composition and the adopted technologyDemand for land, which is already scarce in cities, for landfilling is reducedThe cost of transportation of waste to far-away landfill sites also gets reduced proportionatelyNet reduction in environmental pollutionEnergy can be recovered from the organic fraction of waste (biodegradable as well as non-biodegradable) basically through two methods as follows:Thermo-chemical conversion: This process entails thermal de-composition of organic matter to produce either heat energy or fuel oil or gas;Bio-chemical conversion: This process is based on enzymatic

How Much does a RDF Plant Cost?

2022-05-16Alternative fuel RDF(refuse derived fuel) or solid secondary fuel is a fuel obtained from waste. RDF contains high-calorie waste components such as plastic, paper, cardboard, textiles, rubber, leather, wood, etc.RDF can be used as main or supplementary fuel in furnaces of cement plants, thermal power plants, metallurgical furnaces. The calculations performed showed the expediency of replacing gas or coal with RDF in the production of cement.The production of cement requires significant energy costs due to the need to maintain the temperature in cement kilns above 2000°C. For each ton of cement produced, typically 60-130 kg of fuel oil, or its equivalent (natural gas, coal), and about 105 kWh of electricity are required. On average, energy, fuel and electricity costs account for up to 40 percent of cement manufacturing costs. Therefore, it is advisable to use alternative fuels obtained from waste in production processes in order to reduce the use of traditional fuels and raw materials by replacing them with

Plant for Production RDF and SRF

2022-05-09Refuse Derived Fuel(RDF) and Solid recovered fuel(SRF) is the final product of a complex production process which is modernly defined as the "chain of differentiation, recovery and recycling of municipal solid waste". RDF/SRF is an excellent fuel with a great energy power and a very limited cost, in addition, turning waste into RDF/SRF also reduces landfill space and many other costs. RDF/SRF Production Process The RDF/SRF preparation process consists of several processes: a primary shredding, screening, separation, removal of ferrous and non-ferrous metals and a final shredding. Different material compositions and specific requirements may increase or decrease certain processes. At the waste treatment site, Minhang Sanitation Company processes overproduction, bulky waste fractions, large packaging and unsorted municipal solid waste by transforming them into waste-derived fuels (RDF) of various qualities. The company specialized in disposal supplies waste incineration plants, but mainly cement plants, for

Fuel Processing for RDF, TDF and SRF

2022-05-05Since the beginning of the 21st century, more and more waste has been generated. In order to cope with the threat to the environment caused by the increase in waste, people have begun to use waste as fuel that can be burned in boilers for power generation or heating. We divide the fuel from waste into RDF, TDF, SRF according to different components and processing method of the waste. RDF(Refuse-derived fuel) is a fuel produced by sorting and shredding combustible materials contained in municipal solid waste (MSW) and industrial waste. Compared to fossil fuels, RDF is more affordable, abundant, and environmentally friendly. SRF(Solid Recovered Fuel) is a fuel produced by drying, filtering, and shredding solid waste, It is usually produced to meet the standards in Europe. The EN 15359 document gives the specifications for classifying SRF. Unlike RDF, SRF is a more refined material that is slightly more efficient than RDF, though it takes a more advanced process to make the fuel. TDF(Tire-derived fuel) is a

Co-processing Waste in Cement Industry

2022-04-21The problem of waste is one of the most urgent on the world agenda, According to the World Bank, the world generates 2.01 billion tonnes of waste every year, with at least 33 percent of that—extremely conservatively—not managed in an environmentally safe manner. Therefore, the most important task is to clear the waste and create a system that will allow separating waste, competently managing its flows, processing it and without harm to nature. Turning the so-called “tailings” into cement, which remain at the waste sorting complexes after the extraction of all useful recyclable materials, is one of the most environmentally friendly and effective solutions to this problem. The use of alternative fuels from municipal solid waste (MSW) in cement production will help global achieve environmental goals.Waste Disposal in the Production of CementLimestone, clay and thermal energy are needed to make cement. The cost of the latter is 30% of all production costs. The cement industry uses a variety of fossil fuels to

Due to the continuing energy cost fluctuations and the discussions on the sustainable protection of resources the cement industry has hardly enabled to reduce its entire energy and power demand as a result of technical optimisation of its cement production. With the rising energy prices, people have successively used petroleum and coal as the main fuel for cement production. Later, people began to explore the use of waste oil and tires. Nowadays, as people pay more and more attention to reducing carbon emissions, the waste-to-fuel technology has become more and more mature, and many cement kilns have begun to use municipal solid waste or industrial and commercial waste as alternative fuels.Substituting Coal and Petcoke with Alternative fuelsCoal and petcoke, two of the most carbon-intensive fuels, are typically used to heat cement kilns. The substituting coal with lower-carbon fuels offers the greatest short-term potential to reduce CO2 emissions in the industry. Most alternative fuels have a lower carbon

Alternative Fuels Pre-Processing Shredder

2022-04-08The GD Series double shaft shredder is designed to be versatile, making it suitable for pre-processing a wide range of solid alternative fuels. It can handle materials from municipal solid waste, industrial and commercial waste, to agricultural and forestry residues, and even automotive and truck tires. These materials are frequently used to produce alternative fuels for incinerators, chain grate furnaces, CFB boilers, and rotary kilns.The winning feature of this shredder is that it is a low speed machine.It consists of two shafts with opposite rotation, independent of each other. The cut takes place thanks to the action of the rotating blades on the fixed blades which are installed on a crosspiece placed between the two shafts. The rotating blades and fixed blades are interchangeable and resharpenable.The distance between them is also adjustable to always have a clean cut. The machine can be equipped with a screening grid that allows to obtain a product of defined dimensions, suitable for use as a

Bioenergy is energy obtained by using biomass as a fuel, and is an alternative energy that can be used as a material of biological resources. Biomass used as an energy source is an organic matter that stores sunlight in the form of chemical energy, which uses wood, wood waste, straw, manure, sugar cane, and other by-products from various agricultural processes as fuel. Bio energy utilization refers to technologies such as chemical, biological, and combustion engineering that use biomass directly or in the form of liquid, gas, solid fuel, or electrical and thermal energy through bio-chemical and physical conversion processes. Industrial shredder is a necessary pretreatment equipment for large-scale utilization of bioenergy. It efficiently and quickly chops biomass materials into small sizes, which helps to improve the efficiency of subsequent processing. For example, in a biomass power plant, an automated industrial shredding system can continuously supply fuel and shred biomass into the required size, which